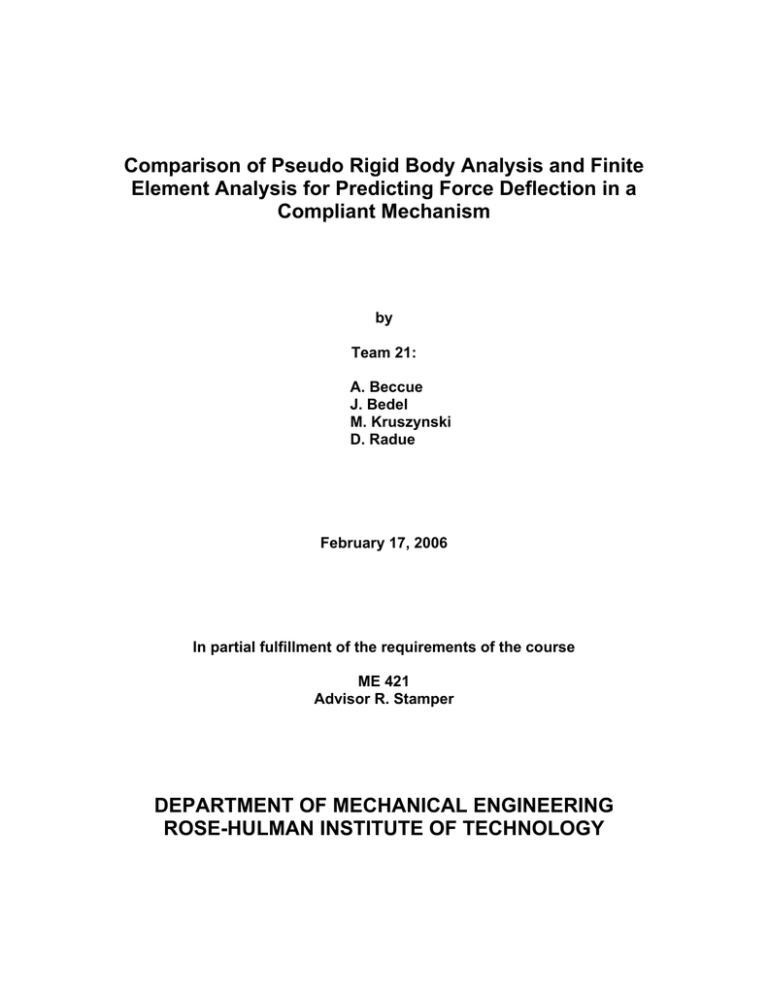

Comparison of Pseudo Rigid Body Analysis and Finite

advertisement

Comparison of Pseudo Rigid Body Analysis and Finite

Element Analysis for Predicting Force Deflection in a

Compliant Mechanism

by

Team 21:

A. Beccue

J. Bedel

M. Kruszynski

D. Radue

February 17, 2006

In partial fulfillment of the requirements of the course

ME 421

Advisor R. Stamper

DEPARTMENT OF MECHANICAL ENGINEERING

ROSE-HULMAN INSTITUTE OF TECHNOLOGY

i

Abstract

Compliant mechanism designers use pseudo-rigid body modeling (PRB) and finite

element analysis (FEA) to predict and refine the behavior of parts prior to physical

prototyping. Although it is generally accepted that FEA produces more accurate results

because it makes fewer geometric assumptions than PRB, the accuracy comes at a

significant expense in modeling time. The conditions in which this expense is warranted

are unclear. In this study, both modeling techniques were used to predict the force

deflection characteristics of an endoscopic handle owned by Cook Urological®. The

results were then compared to experimental data in order to assess the accuracy of the

models and draw conclusions about their applicability.

When predicting the force-deflection curve for vertical actuation of the handle, both

models deviated significantly from experimental results. Neither modeling technique

captured the experimental response within bounds that accounted for material variation

and other key modeling assumptions. The FEA model was more accurate; through 1.5

inches of deflection, the FEA had an average of 184% deviation from the experimental

results while the PRB averaged 450% deviation. However, the FEA required between

seven and ten times the man-hour investment to develop. Ultimately the study suggests

that PRB might be more viable when modeling inaccuracy can be efficiently overcome

through prototype refinement while FEA seems viable when prototype refinement is costprohibitive and modeling assumptions errors can be limited.

ii

Table of Contents

Section Title

Page

List of Figures ..…….……………………………………….………………...………….iii

Nomenclature ……….……………………………………….………………...………….iv

1. Background ...…………………………………………………………………..………1

2. Objective ..……………………………………………………………………..………1

3. Test Parts ………....………….…………………………………………………..…….1

4. Experimental Setup and Methods …...............................................................................2

4.1 Experimental Apparatus……….....…………...…………………………………2

4.2 Experimental Protocol …………………...…...…………………………………2

5. Pseudo-Rigid Body Model ..………...……………………………………..…………..3

5.1 Pseudo-Rigid Body Modeling Methods ....…...…………………………………3

5.2 Pseudo-Rigid Body Model Development and Refinement...……………………4

6. Finite Element Analysis Model .……...……………………………………..…………4

6.1 Initial Finite Element Analysis Model ...……...…………………………………4

6.2 Finite Element Analysis Refinements ………..….………………………………5

7. Results ..………….……………….……………………………………………............6

8. Conclusions and Recommendations ..……….…………………………………………5

9. References ..………….……………….…………………………………………….....6

10. Acknowledgements ..………….……………….……………………………………6

Appendices …….……………………………………………..............……………...... A-1

A: Testing Apparatus…………………..............……………….………………... A-1

B: Sample Calculations……………………..............………..……………….......A-1

C: Vendor Information……………………..............…………………………......A-4

D: Raw Data…………………………..............………...……………….............. A-5

E: Computer Code…………………………..............……………...……………. A-6

F: Task Breakdown…………………………..............……………...…………… A-7

iii

List of Figures

Figure Name

Page

Figure 1: Cook® Endoscopic Handle in Packaging ..……..….………………...………….1

Figure 2: Handle Terminology ..……………………..…...….………………...………….2

Figure 3: Handle in Fixture with Measurand Detail ...……….………………...………….3

Figure 4: Pseudo-Rigid Body Model Schematic …………….………………...………….4

Figure 5: Initial Finite Element Model ...…………………….………………...…………5

Figure 6: Force Application Point Detail for Final Finite Element Model .…...………….6

Figure 7: Sample Part Comparison ………………………….………………...………….7

Figure 8: FEA Force-Deflection Curves .…………………….………………...………….7

Figure 9: PRB Force-Deflection Curves .…………………….………………...………….8

Figure 10: Comparison of Average Force-Deflection Curves….……………...………….9

iv

Nomenclature

Symbol

Quantity

F

Vertical Actuator Force (lbf) (See Figure 3)

Y

Vertical Actuator Displacement (in) (See Figure 3)

a, b, c, d

Link Lengths (in) (See Figure 4)

θ2, θ 3

Reference Angles (rad) (See Figure 4)

K1, K2

Torsion Spring Constants (in·lbf/rad) (See Figure 4)

1

1

Background

When designing compliant mechanisms, there are multiple analytical approaches for

predicting part performance. These tools are often used to reduce development costs by

facilitating design refinement prior to physical prototyping. Pseudo-rigid body modeling

(PRB) and finite element analysis (FEA) are two such methods for predicting the

performance of compliant mechanisms. PRB treats the compliant mechanism as a series

of rigid links connected by springs, and then applies classical mechanics. FEA solves the

differential equations of stress in the body with numerical methods by breaking the model

into small elements and balancing forces on all elements simultaneously with matrix

algebra. Of the two methods, FEA requires significantly more time and resources to

develop than PRB; however, FEA is generally expected to be more accurate.

2

Objective

The objective of this research is to compare the force-deflection characteristics of a

compliant mechanism with predictions from FEA and PRB. The viability and

applicability of these techniques, with regard to compliant mechanism design, is to be

determined.

3

Test Parts

A self-tensioning endoscopic device handle from Cook Urological® is the focus of this

study. This part was originally designed using PRB and recently was the subject of an

FEA course at Rose-Hulman Institute of Technology. It was selected for this study

because of these previous analyses and at the behest of its original designer, Dr. Richard

Stamper. In Figure 1 this part is shown as packaged for use. In Figure 2 the part is

labeled to identify applicable terminology.

Figure 1: Cook® Endoscopic Handle in Packaging

2

Vertical

Actuation

Point

Finger Grip

Base

Crank

Slide

Cylinder

Slide Track

Figure 2: Handle Terminology

4

Experimental Setup and Methods

4.1 Experimental Apparatus

The experimental apparatus for measuring force deflection of the handle consists of a

handle fixture, an MTS – 858 Table Top System, and a 5N load cell (See Appendix A for

details). Shown in Figure 3 is a schematic of the handle and experimental apparatus.

The measurands, vertical actuator force (F) and vertical actuator displacement (Y), are

labeled. The handle fixture was fabricated out of ABS (acrylonitrile butadiene styrene)

using a fused-deposition modeler, and it allows the handle to interface with the lower

grips of the MTS system while rigidly fixing the handle base. The vertical actuator of the

MTS system directly contacts the handle. The load cell is attached to the vertical actuator

and records strain data which is used by the associated software to calculate the force

applied by the actuator. The actuator displacements are directly recorded.

4.2

Experimental Protocol

The experimental protocol is performed by the software integrated with the MTS system.

After the handle is fixed, the actuator depresses the handle a total of 1.75 inches at a rate

of 0.05 in/sec, recording data every 0.01 seconds. The actuator returns to its starting

position before the next trial. During data reduction the data set is cropped such that the

first point is the point when the actuator first registers a reaction force from the handle.

For the purposes of this study, eight trials were performed on two different handle

samples.

3

Actuator, MTS Table Top System

Handle

F

Y

Handle Fixture

Lower Grips, MTS Table Top System

Figure 3: Handle in Fixture with Measurand Detail

5

Pseudo-Rigid Body Model

5.1 Pseudo-Rigid Body Modeling Methods

PRB modeling is a technique where a single, complex, flexible member is assumed to be

several rigid members with springs connecting the members at specific points in an effort

to mimic the kinematics of original flexible member. PRB analysis uses kinematic and

static mechanics to relate equations of motion to external forces applied at specified

points on the members. For compliant mechanisms that incorporate compliant joints, the

joints are replaced by torsional springs with characteristic spring constants that depend on

material and geometric properties. For more on PRB, see Compliant Mechanisms, by

Larry Howell. In order to model flexible beams as two rigid members connected with a

spring, the spring has to have both a characteristic spring constant and a characteristic

spring length which accounts for the distance that the spring is away from a specified

end. Unlike the characteristic spring constant, the characteristic spring length does not

rely on material or geometric properties but is simply chosen to be a length that best

describes the angular deflection path of the original body.

4

b

Y

K1

a

F

θ2

K2

c

θ3

d

Figure 4: Pseudo-Rigid Body Model Schematic

5.2 Pseudo-Rigid Body Modeling Development and Refinement

The PRB model was a modification of Dr. Stamper’s original analysis used to design the

handle. The principle change is to treat the crank member as a flexible beam, because it

tends to undergo large deflections. A diagram of the schematic for the final PRB model

is shown in Figure 4 (see the Nomenclature Section for variable definition). The final

model consists of two springs, one that models the junction between the base and the

finger grip and a second that models the bending in the crank member. It is of note that

although there appears to be a joint between the finger grip and the crank, this section of

the part was reinforced such that it behaved nearly rigidly. This is why the second

torsional spring is positioned on the crank and not at the junction between the crank and

the finger grip. See Appendix B for a thorough derivation of the relevant equations for

the PRB model.

6

Finite Element Analysis Model

6.1 Initial Finite Element Analysis Model

The finite element analysis for the handle is a modification of work performed by the

spring 2005 Advanced Finite Element Analysis class (ME 522) at Rose-Hulman Institute

of Technology, instructed by Dr. Lorraine Olson. The original FEA model treats the

handle in two dimensions. The part is broken into eighteen individually meshed areas, as

shown in Figure 5a, and the depth of each area varies to account for differences in part

thickness. Two element types are used: quadrilateral 8-node (Ansys #183) and triangular

5

6-node (Ansys #2). The model uses material properties defined by the manufacturer’s

product specifications for silicon lubricated, 10% glass fiber-reinforced nylon 6/6 (RTP

201 SI 2) (See Appendix 3 for data sheet). The material is treated as linear, elastic, and

isotropic. Boundary conditions on the part are assessed as fixed displacements in the xand y-directions at the base and in the y-direction at the slide-cylinder and vertical

actuation point (See Figure 5b). Note that much of the base is excluded from the model

because it is assumed to be rigid in comparison to the finger-grip and crank members.

Because the geometry of the part is non-linear, analysis was performed through a

progression of small deflections. Several meshing iterations were performed until the

solution converged for each progressive deflection.

Figure 5a: FEA Mesh Areas

Figure 5b: FEA Displacement Nodes

Figure 5: Initial Finite Element Model

6.2 Finite Element Analysis Refinements

The final FEA model modifies the initial two-dimensional FEA model to account for the

specific loading conditions of the experimental setup and changes in the geometry of the

sample parts due to stress relaxation. In the experiment the vertical actuation force is

applied normally to the surface of the handle. As the part deflects, the force application

point shifts (shown in Figure 6a and 6b). Because this boundary condition cannot be

readily adapted to the finite element model, there are two model versions. In the first

version the force is constantly applied at the rightmost possible application site, and in

the second version, the leftmost application site is used. This technique bounds the range

of curves associated with variations in the force application point. The second major

revision to the model is in starting geometry. When the parts are molded, the slidecylinder is positioned outside the slide track. In the sample parts, however, the slidecylinder has been moved to the slide track and allowed to stress relax. The initial FEA

model uses the geometry of the handle as-molded, not the stress-relaxed geometry, and it

uses an extra deflection step to position the slide-cylinder against the slide track. This

step adds stresses that are not present in the physical piece. To account for this deviation,

the model is revised to use the nodal coordinates after re-positioning of the slide-cylinder

as the initial nodal coordinates without including the pre-stresses.

6

Right-most Point of Force Application

Figure 6a: Undeflected Model

Left-most Point of Force Application

Figure 6b: 1.5 in. Vertically Deflected Model

Figure 6: Force Application Point Detail for Final Finite Element Model

7

Results

Figures 7, 8, and 9 display the force deflection curves of the two modeling techniques

and the experimental values. There are two sets of data for each model in order to

account for the biases that affect each. The experimental data for the two parts differed

by an average of 0.49 lbf at 1.5 inches of deflection (see Figure 7). The two FEA

analysis data sets account for the change in the application point of the force and

uncertainty in the modulus of elasticity of the material. They differ from each other by

44% of the average value. The PRB model varied with the positions of the torsional

springs and the lengths of the rigid body members, specifically the placement of spring

along the length of the crank. The difference between the final values of the PRB model

is 18% of the average force deflection curve.

7

Vertical Actuator Force (lbf)

3.00

2.50

Average

2.00

Part 2

avg

diff= .49

1.50

Part 1

1.00

0.50

0.00

0.00

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

Vertical Displacement (in.)

Figure 7: Sample Part Comparison

8.00

FEA Upper Limit: Node 228, E=6E05

7.00

Average FEA

6.00

avg diff=

2.2 lbf

Force (lbf)

5.00

4.00

FEA Lower Limit: Node 246, E=4E05

3.00

2.00

1.00

0.00

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

Displacement (in.)

Figure 8: FEA Force Deflection Curves

1.60

1.80

2.00

8

16.00

14.00

PRB Upper Limit

12.00

PRB Average

Force (lbf)

10.00

PRB lower Limit

avg diff. =

1.71 lbf

8.00

6.00

4.00

2.00

0.00

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

2.00

Deflection (in.)

Figure 9: PRB Force Deflection Curves

Figure 10 shows a comparison of the average force deflection curves for the two analysis

methods and the experimental results. The FEA analysis predicts values that are 184%

(of the average experimental value) higher than the experimental values. The average

FEA force was 4.90 lbf while the average value of the actual experimental data was 1.72

lbf. The PRB model predicts values that are 450% (of avg. exp. values) higher than the

experimental values. The average value predicted by the PRB model was 9.53 lbf.

While the predicted values are significantly higher than those of the experimental values,

the shape of the curves show some resemblance to the force deflection curve of the actual

parts.

9

14.00

12.00

Force (lbf)

10.00

PRB

8.00

avg diff=

7.8 lbf

FEA

6.00

avg diff=

3.2 lbf

4.00

Experimental

2.00

0.00

0.00

0.20

0.40

0.60

0.80

1.00

1.20

1.40

1.60

1.80

2.00

Displacement (in.)

Figure 10: Comparison of Average Force Deflection Curves

8

Conclusions and Recommendations

PRB and FEA do not accurately (within 10%) predict the experimental force deflection

curve of the handle; however, this should not be interpreted as a complete modeling

failure. Both PRB and FEA come within an order of magnitude of the experimental

values and give some semblance of the final force deflection characteristics.

Between the two methods, PRB is the less complicated method, but it is also predicts the

handle force-deflection curve with less accuracy. This might be more acceptable for an

application in which prototyping costs are low, because it could be the analysis

completed quickly and inaccuracies could be overcome through prototype revision. By

contrast, the FEA model requires significantly more time and computing power to

implement. When factoring in the time invested by Dr. Stamper to make the original

PRB and the time invested by the ME 522 class in making the FEA model, FEA required

seven to ten times the man hours of PRB to complete. For the handle, this investment

more than doubled the average model accuracy, but the FEA model still had an average

error of 184%. The relative accuracy gain associated with FEA instead of PRB might be

appropriate if prototype iteration is cost-prohibitive.

It is worth noting that the accuracy of the either method is dependent upon the

assumptions inherent to the method and the assumptions made by the designer. FEA

generally captures more part geometry than PRB, but geometry is not the only driving

factor in compliant mechanisms. Material properties and boundary conditions are other

factors that require modeling assumptions. If a designer needs to predict part

10

performance with a high degree of accuracy, the selection of FEA instead of PRB does

not guarantee an accurate model, as indicated in this study. An accurate representation of

material properties and boundary conditions may be just as crucial in producing an

accurate model.

9

References

Howell, Larry L. Compliant Mechanisms. New York: John Wiley and Sons, 2001.

10

Acknowledgements

Team 21 would like to thank the following individuals and companies for contributing to

our experimentation and modeling. Their contributions were critical for our work.

Dr. Richard Stamper – project advisor, proposed Cook handle analysis, provided initial

PRB analysis and Compliant Mechanisms

Dr. Lorraine Olson – provided initial FEA model, advised FEA model modification and

refinement

Gary Burgess – provided access to the MTS tensile tester, assisted in testing protocol

development, fabricated test fixture

Rob Davignon – provided sample parts, provided material product sheets, provided

Solidworks® access for test fixture design.

RTP Company – provided information about the material properties of the handle

Cook Urological

A-1

A

Testing Apparatus

MTS – 858 Table Top System, #1288496

5N Load Cell – 661.11B-02, #101373

MTS Systems Corporation

14000 Technology Drive

Eden Prairie, MN 55344

Stratasys FDM 3000, #2283

Stratasys, Inc.

14950 Martin Drive

Eden Prairie, MN 55344

A-2

B

Sample Calculations

Pseudo-Rigid Body Analysis

Kinematics equations

ai + b cos θ 2 + bi sin θ 2 = d + c cos θ 3 + ci sin θ 3

where a

b

c

d

θ2

≡

≡

≡

≡

≡

(1.1)

link length, in

link length, in

link length, in

link length, in

angle, rad

θ 3 ≡ angle, rad

b cos θ 2 = d + c cos θ 3

(1.2)

a + b sin θ 2 = c sin θ 3

(1.3)

⎛ a + b sin θ 2 ⎞

⎟

c

⎝

⎠

θ 3 = sin −1 ⎜

d = cos θ 2 − c cos θ 3

(1.4)

(1.5)

Free body diagram of link b equations

∑F

x

=0

F12x + F32x = 0

(2.1)

where F12x ≡ positive horizontal reaction force at B, lbf

F32x ≡ positive horizontal reaction force at C, lbf

∑F

y

=0

F12y − F + F32y = 0

(2.2)

where F12y ≡ positive vertical reaction force at B, lbf

F32y ≡ positive vertical reaction force at C, lbf

∑M

F ≡ negative vertical force applied to handle, lbf

B

=0

T12 − F b cos θ 2 − F32y b cos θ 2 − F32x b sin θ 2 + T32 = 0

(2.3)

where T12 ≡ positive counterclockwise reaction torque at B, lbf-in

T32 ≡ positive counterclockwise reaction torque at C, lbf-in

T12 = K 1 (θ 2, 0 − θ 2 )

where K1 ≡ Characteristic spring constant at B, lbf-in/rad

θ 2,0 ≡ Initial θ 2 , rad

(2.4)

A-3

T32 = − K 2 [(θ 3, 0 − θ 2, 0 ) − (θ 3 − θ 2 )]

(2.5)

where K 2 ≡ Characteristic spring constant at C, lbf-in/rad

θ 3,0 ≡ Initial θ3 , rad

Spring constant equations

K1 =

EI1

l1

(3.1)

where E ≡ Flexural modulus, psi

I1 ≡ 2nd moment of area, in4

l1 ≡ length of spring, in

K 2 = πγ 2

EI 2

l2

(3.2)

where I2 ≡ 2nd moment of area, in4

l2 ≡ length of spring, in

γ ≡ characteristic spring radius fraction

Free body diagram of link c equations

∑F

x

=0

μ F13x + F23x = 0

(4.1)

where F23x ≡ positive horizontal reaction force at C, lbf

F13x ≡ positive horizontal reaction force at D, lbf

μ ≡ friction coefficient

∑F

y

=0

F13y + F23y = 0

(4.2)

where F23y ≡ positive vertical reaction force at C, lbf

F13y ≡ positive vertical reaction force at D, lbf

∑M

D

=0

T23 + F23y c cos θ 3 − F13x c sin θ 3 = 0

(4.3)

where T23 ≡ positive counterclockwise reaction torque at C, lbf-in

Friction equation

F13x = μ F13y

(5.1)

Relate θ 2 to measurand Y

⎛Y − a ⎞

sin −1 ⎜

⎟ = θ2

⎝ b ⎠

where Y ≡ Input deflection, in

(6.1)

A-4

Force-Deflection Equation (from eq 3.2)

F=

T12 + F32y b cos θ 2 − F32x b sin θ 2 + T32

b cos θ 2

(7.1)

A-5

Data Analysis

Average difference between the values of force deflection for parts 1 & 2

n

∑ (Part1

Avg _ diff _ Parts =

i

i =1

− Part 2 i )

(8.1)

n

where Part 1 → experimental force data array from the MTS machine for part 1

Part 2 → experimental force data array from the MTS machine for part 2

n ≡ array length

Average difference between the values of force deflection for PRB

n

∑ (PRB1

Avg _ diff _ PRB =

i

i =1

− PRB 2 i )

n

where PRB1 → force data array from the PRB model for spring placement 1

PRB2 → force data array from the PRB model for spring placement 2

n ≡ array length

∑ (PRB

n

Avg _ diff _ PRBoverall =

i =1

avg ,i

(9.1)

− MTS avg ,i )

(9.2)

n

where PRBavg → array of average values of forces for spring placement in the

PRB model

MTSavg → array of average values of forces from the MTS machine for

both Part 1 and Part 2

n ≡ array length

Average difference between the values of force deflection for FEA

n

Avg _ diff _ FEA =

∑ (Node1

i

i =1

− Node2 i )

n

where Node1 → force data array from the FEA model for left-most force

application node

Node2 → force data array from the FEA model for right-most force

application node

n ≡ array length

∑ (FEA

n

Avg _ diff _ FEAoverall =

i =1

avg ,i

(10.1)

− MTS avg ,i )

(10.2)

n

where FEAavg → array of average values of forces for force application node in

the FEA model

MTSavg → array of average values of force deflection from the MTS

machine for both Part 1 and Part 2

A-6

n

≡ array length

A-7

C

Vendor Information

Product Data Sheet & General Processing Conditions

RTP 200 Nylon 6/6 (PA)

PROPERTIES & AVERAGE VALUES OF INJECTION MOLDED SPECIMENS

ASTM

PERMANENCE

English

SI Metric TEST

Specific Gravity

Molding Shrinkage

1/8 in (3.2 mm) section

1.14

1.14

D 792

0.0150 in/in

1.50 %

D 955

MECHANICAL

Impact Strength, Izod

notched 1/8 in (3.2 mm) section

unnotched 1/8 in (3.2 mm) section

Tensile Strength

Tensile Elongation

Tensile Modulus

Flexural Strength

Flexural Modulus

1.0 ft-lbs/in

20.0 ft-lbs/in

12000 psi

> 10.0 %

0.40 x 10^6 psi

15500 psi

0.40 x 10^6 psi

53 J/m D 256

1068 J/m D 4812

83 MPa D 638

> 10.0 % D 638

2758 MPa D 638

107 MPa D 790

2758 MPa D 790

THERMAL

Deflection Temperature

@ 264 psi (1820 kPa)

Ignition Resistance*

Flammability**

150 °F

66 °C

D 648

HB @ 1/16 in

HB @ 1.5 mm

D 635

PROPERTY NOTES

Data herein is typical and not to be construed as specifications.

Unless otherwise specified, all data listed is for natural or black colored materials.

Pigments can affect properties.

* This rating is not intended to reflect hazards of this or any other material under actual

fire conditions.

** Values per RTP Company testing.

A-8

GENERAL PROCESSING FOR INJECTION MOLDING

English

Injection Pressure

Melt Temperature

Mold Temperature

Drying

Moisture Content

Dew Point

10000 - 18000 psi

530 - 570 °F

150 - 225 °F

4 hrs @ 175 °F

0.20 %

0 °F

SI Metric

69 - 124 MPa

277 - 299 °C

66 - 107 °C

4 hrs @ 79 °C

0.20 %

-18 °C

PROCESSING NOTES

Desiccant Type Dryer Required.

10 Aug 2004 KMH

RTP COMPANY • 580 EAST FRONT STREET • WINONA, MN 55987 • 507-454-6900

D

Raw Data

The raw data is available in electronic form at the following address:

http://www.rose-hulman.edu/~kruszymm/raw_data.xls

E

Computer Code

load('specimen1.dat')

test1_1(:,1)=abs(specimen1(:,1)-specimen1(1,1));

test1_1(:,2)=abs(specimen1(:,2)-specimen1(1,2))/4.448;

load('specimen2.dat')

test1_2(:,1)=abs(specimen2(:,1)-specimen2(1,1));

test1_2(:,2)=abs(specimen2(:,2)-specimen2(1,2))/4.448;

load('specimen3.dat')

test1_3(:,1)=abs(specimen3(:,1)-specimen3(1,1));

test1_3(:,2)=abs(specimen3(:,2)-specimen3(1,2))/4.448;

load('specimen4.dat')

test1_4(:,1)=abs(specimen4(:,1)-specimen4(1,1));

test1_4(:,2)=abs(specimen4(:,2)-specimen4(1,2))/4.448;

load('specimen5.dat')

test1_5(:,1)=abs(specimen5(:,1)-specimen5(1,1));

A-9

test1_5(:,2)=abs(specimen5(:,2)-specimen5(1,2))/4.448;

load('specimen6.dat')

test1_6(:,1)=abs(specimen6(:,1)-specimen6(1,1));

test1_6(:,2)=abs(specimen6(:,2)-specimen6(1,2))/4.448;

load('specimen7.dat')

test1_7(:,1)=abs(specimen7(:,1)-specimen7(1,1));

test1_7(:,2)=abs(specimen7(:,2)-specimen7(1,2))/4.448;

load('specimen8.dat')

test1_8(:,1)=abs(specimen8(:,1)-specimen8(1,1));

test1_8(:,2)=abs(specimen8(:,2)-specimen8(1,2))/4.448;

count2=2;

data1(1,1)=0;

data1(1,2)=0;

for i1=0.01:.01:1.50

count=0;

force=0;

for i2=1:size(test1_1,1)

if (i1-.005)<test1_1(i2,1) && test1_1(i2,1)<(i1+.0049)

force=force+test1_1(i2,2);

count=count+1;

end

end

for i2=1:size(test1_2,1)

if (i1-.005)<test1_2(i2,1) && test1_2(i2,1)<(i1+.0049)

force=force+test1_2(i2,2);

count=count+1;

end

end

for i2=1:size(test1_3,1)

if (i1-.005)<test1_3(i2,1) && test1_3(i2,1)<(i1+.0049)

force=force+test1_3(i2,2);

count=count+1;

end

end

for i2=1:size(test1_4,1)

if (i1-.005)<test1_4(i2,1) && test1_4(i2,1)<(i1+.0049)

force=force+test1_4(i2,2);

count=count+1;

end

end

A-10

for i2=1:size(test1_5,1)

F

Task Breakdown

Task No.

Task

1

2

3

3a

3b

3c

3d

4

4a

4b

4c

4d

5

5a

5b

5c

5d

5e

6

6a

6b

6c

6d

6e

7

7a

7b

Potential Project Idea Generation/Write-up

Preliminary Project Plan

Design/Construct Fixture

Access and Examine Instron Tensile Tester

Access Solid Model of Handle

Create Fixture Model

Fabricate Fixture

Develop Pseudo-rigid Body Model

Research Compliant Mechanisms

Access and Modify Dr. Stamper’s Model

Verify Dimensions/Values

Verify Modeling Assumptions/Techniques

Develop Finite Element Model

Access Dr. Olson’s FEA Model

Learn How to Modify the FEA Model

1st Pass Modification

2nd Pass Modification

3rd Pass Modification

Data Collection

Preliminary Measurement Run

1st Pass Data Collection

2nd Pass Data Collection

3rd Pass Data Collection

Final Data Collection

Data Analysis/Manipulation

Preliminary Data Organizing/Formating

Determine Statistical Methods

Matlab Script Writing for Data

Extraction/Statistical Analysis

Finalize Plotting/Data Presentation

Progress Report

Task Breakdown

Task Breakdown Updating (periodic)

Mid-Project Presentation

Develop Preliminary Presentation Slides

Revise Presentation Slides

Rehearse Presentation

Revise Project Plan

Final Report

Rough Draft

1st Pass Revision

2nd Pass Revision

3rd Pass Revision

Final Revision

Project Evaluation

7c

7d

8

9

9a

10

10a

10b

10c

11

12

12a

12b

12c

12d

12f

13

Time to

Accomplish*

(hr.)

0.75

1

4.5

0.75

1

2

2

4

1

1.5

1

4.5

19.5

1

3

2

4.5

2

5

1

1

2

1

1

11

4

2

Responsible

Person

Due Date

Status

Team

Team

J.B., D.R.

Team

J.B., D.R.

J.B., D.R.

G.Burgess

A.B.,M.K.

A.B.,M.K.

M.K.

M.K.

A.B.

D.R.

M.K.,D.R.

D.R

D.R

D.R

D.R.

A.B,J.B.

Team

A.B.,J.B.

J.B

J.B

A.B,J.B

M.K.

M.K.

M.K.

11/29/05

12/1/05

12/8/05

12/1/05

12/5/05

12/7/05

12/8/05

1/6/06

12/7/05

12/13/05

1/6/06

1/6/06

2/3/06

12/5/05

12/8/05

12/9/05

1/4/06

1/9/06

1/18/05

12/9/05

12/12/05

1/4/06

1/27/06

2/1/06

2/3/06

12/14/05

1/6/06

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete

3

M.K.

1/6/06

Complete

2

0.75

1.5

3.5

4.5

1

1.5

2

1

M.K.

A.B.,J.B.,D.R.

M.K.,D.R.

A.B.

Team

Team

Team

Team

Team

Team

Team

Team

Team

Team

Team

Team

1/25/06

12/20/05

12/20/05

Periodic

1/11/06

12/14/05

1/8/06

1/10/06

Unknown

2/17/06

1/27/06

2/1/06

2/6/06

2/8/06

2/14/06

Unknown

5

3

3

3

5

1

*Hours are listed per person for each of the persons responsible

Complete

Complete

Complete

Complete

Complete

Complete

Complete

Complete