Design Phase Presentation

advertisement

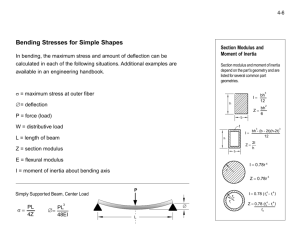

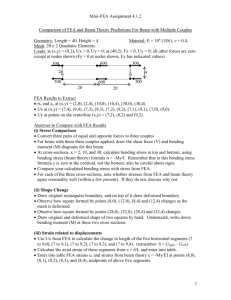

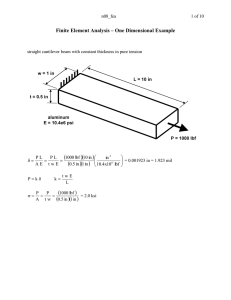

DESIGN PHASE What kind of analysis you need to do? MIME Senior Design Projects - Spring 2013 Overview Design/Analysis Requirements Common Design Issues Welds Fatigue Safety Quality Design Requirements What type of analyses do I need? Technical Analysis Description Examples 1 Static Analysis Calculate forces and moments for stationary Lifts, supports, structures, connections. components. 2 Dynamic Analysis Calculate s, v, a of moving components and All moving components such as gears, the forces and torques needed. mechanisms, pulleys, 3 Power Analysis Calculate the power needed to run the machine. Use the force and dynamic 4 Stress Analysis inclg FEA Calculate stresses and compare with strengths to see if failure would occur. Components under high forces, moments or torques such as support members. 5 Thermal Analysis Calculate temperature, temp changes, pressures, and possibly heat transfer. Components including fluids where heat and temperature are involved. 6 Fluid Flow Analysis Calculate flow rate, speed, quantity, pressure, and possibly temperature. Determine pump sizes, pipe diameters, flow measurement when you have fluids. 7 Process Analysis 8 Vibration Analysis 9 Cost Analysis Improve business activities in order to reduce overall costs, provide more efficient Lean manufacturing, six sigma and total quality use of resources, and to better support and management. add value for customers. Determine vibration frequency, and if vibration will be a problem. Anything moving with a certain frequency. Also some electrical components. Determine the costs in the short run and long run, as well as ROI. Determine if it is more cost effective to produce or to outsource a component. Design Requirements Measure twice, cut once Make sure you do adequate calculations and analysis Tendency to build first, design later Works if you’re right the first time Costs material, effort, and time if you’re wrong Anticipate use Anticipate misuse! Design/Analysis FREE BODY DIAGRAM FEA Approximate Design/Calculations Is it a beam or a plate? Design/Analysis - FEA Quality of input determines quality of output “Magic” Black Box Factors Solid model quality Correct boundary conditions Load accuracy Proper material selection Mesh quality Correct Failure Criteria Design/Analysis - FEA Solid Model Quality Balance simplicity/accuracy Use your intuition to include features that will increase stresses Exclude trivial features Correct Boundary Conditions Make sure your restraints accurately represent real conditions Check degrees of freedom Check fastener/mating conditions in assemblies Design/Analysis - FEA Load Accuracy What type of loading? point load? distributed load? Am I missing loads? thermal? centripedal? What is the magnitude? 10lbs? 500lbs? 1,000,000lbs? Rationalize with intuition Determine with testing Material Selection Did I select the correct material? Are my properties in the correct units? FEA – What to expect? http://machinedesign.com/article/fe-update-expecting-too-much-from-fea-0710 Design/Analysis - FEA Mesh Quality Make sure it is fine enough to accurately depict features Affects processing time Design/Analysis - FEA Correct Failure Criteria Stress based: yielding or fracture? Excessive displacement Loss of function Corrosion Thermal degradation Fatigue Remember that ductile and brittle materials fail differently and have different failure criteria! Design/Analysis When in doubt, do some hand calculations Mathcad and Matlab are very useful Shigley is very useful DANotes is a good resource as well: http://www.mech.uwa.edu.au/DANotes/ Your basic calculations and FEA should support each other If they don’t, you should know why Welds Strength of welds Location- sharp corners? Loading- stress state of weld? Size Quality of weld! Fatigue Fatigue Are their cyclic loads? Do fatigue analysis S/n approach used in Shigley Safety Pinch points? Sanitation? Exposed wiring? Warnings? Quality Deliverables should function well Make sure products are durable Double-check safety References References: What Kind of Analysis do you Need for your Project?, Dr. Kramer, MIME Dept. Photo Credits: http://www.msha.gov/Accident_Prevention/Tips/im ages/HandTools-Jacks.jpg http://machinedesign.com/article/fe-updateexpecting-too-much-from-fea-0710