Document 11563087

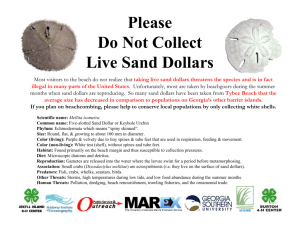

advertisement