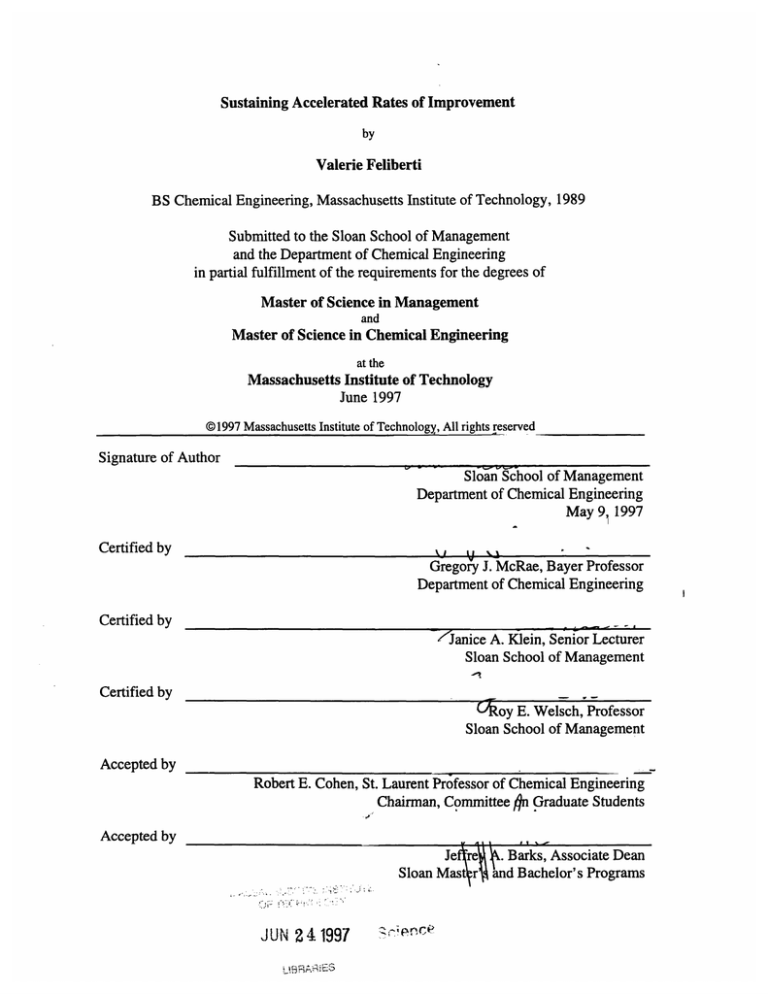

Sustaining Accelerated Rates of Improvement Valerie Feliberti

advertisement