Manufacturing of Lab-on-a-Chip Devices:

advertisement

Manufacturing of Lab-on-a-Chip Devices:

Variation Analysis of Liquid Delivery using Blister Packs

by

Sivesh Selvakumar

B.E. Mechanical Engineering (2009)

College of Engineering, Guindy, India

Submitted to the Department of Mechanical Engineering

in Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Manufacturing

at the

MASSACHUSETTS INSTITUTE

OF TECHNOLOGY

Massachusetts Institute of Technology

NOV 0 4 2010

September 2010

LIBRARI ES

© 2010 Sivesh Selvakumar

All rights reserved

ARCHIVES

The author hereby grants to MIT permission to reproduce and to

distribute publicly paper and electronic copies of the thesis document in whole or in part

in any medium now known or hereafter created

Signature of Author............

..........

e artm t of Mechanical Engineering

..

g..

..'21ust 2 " 10

.......

. .......

Certified by...........

A..h.

....

Lectu

71

epartment of Mecanical Engineering

A

-"Ii

ThesMwSupervisor

A ccepted by............................................

David E. Hardt

Chairman, Committee on Graduate Students

This page has been intentionally left blank

Manufacturing of Lab-on-a-Chip Devices:

Variation Analysis of Liquid Delivery using Blister Packs

by

Sivesh Selvakumar

B.E. Mechanical Engineering (2009)

College of Engineering, Guindy, India

Submitted to the Department of Mechanical Engineering

in Partial Fulfillment of the Requirements for the Degree of

Master of Engineering in Manufacturing

Abstract

Components for on-chip storage and delivery of liquid reagent are necessary for many

commercial applications of lab-on-a-chip technology. One such system uses a 'blister pack' that

is pushed by an actuator. Over the course of product development, Daktari Diagnostics had

completed nominal design of a blister pack for their flow rate requirements. This work involved

performing a thorough variation analysis of the blister pack to determine the critical sources of

variation.

For this purpose, the tool of variation simulation modeling (VSM) was used. A numerical model

of the blister performance was developed and Monte Carlo simulations were conducted. The

results showed that this fluid delivery technique is robust and the number of out-of-specification

parts was less than 2%. The critical blister pack parameters that must be controlled were also

determined and these can be used to improve process capability.

Thesis Supervisor: Dr. Brian Anthony

Title: Lecturer

4

Acknowledgements

I wise to convey my gratitude to:

Aaron, Bill, Robert, Peter,Andy and Betsy, for being such great hosts at Daktari Diagnostics.

Your enthusiasm and drive for the tasks at hand never ceased to amaze me. Working for Daktari

has been an absolute pleasure.

Rodrigo, my team-mate and friend, for his motivation and for the 'occasional' advice. Much of

this work owes its existence to your input and hard work. It has been a pleasure to work with you.

Dr. BrianAnthony, our thesis advisor, for his support and encouragement throughout what has

been, in many ways, a unique project experience.

Jennifer Craig, our writing advisor, who surely spent many hours reading several last-minute

drafts. Without her support and eye for detail, this thesis would have suffered in quality.

The folks at the Edgerton Student Shop for their understanding and much-needed suggestions

through many hours of machining. This project has gained a lot from their experience.

Amma, Appa and Appayya for making all of this possible.

6

Table of Contents

Acknowledgements

5

Table of Contents

7

List of Figures

11

List of Tables

13

1. Introduction

15

1.1 The M.Eng. Capstone Project

16

1.2 Overview of the Thesis

16

2. Product and Project Overview

19

2.1 Company Background

19

2.2 ProductDescription

19

2.2.1 The Cartridge

20

2.2.2 The Instrument

21

2.2.3 Product Timeline

22

2.3 Problem Statement

23

2.3.1 Survey of Manufacturing Issues

23

2.3.2 Selection of Subset of Problems

25

3. Background Research

3.1 Lab-on-a-ChipApplications

3.1.1 CD4+ Cell counting through Cell Lysate Impedance Spectroscopy

3.2 MicrofluidicDevice Architecture

27

27

27

28

3.2.1 Central Layer

29

3.2.2 External Layer

29

3.2.3 Additional Components

29

3.3 Lab On a Chip Technologies

30

3.4 Lab-on-a-Chip ManufacturingProcesses

31

3.4.1 Part Manufacturing

31

3.4.2 Functionalization Process

32

3.5 Monte CarloAnalysis

33

3.6 Machine Vision for Metrology

34

3.6.1 Choice of Metrology System

34

5.1.2 Components of a Machine Vision System

34

4. Development of the Blister Performance Model

37

4.1 Working of the DaktariBlister Pack

37

4.2 Requirements of the Blister Numerical Model

38

4.2.1 Blister Outputs and Noise Factors

4.3 The Numerical Model

40

41

4.3.1 Input Blister Dimensions and Speed of Travel

43

4.3.2 Step Size

43

4.3.3 Determine Actuator Positions according to Step Size and Misalignment

44

4.3.4 Calculate the total volume of fluid expelled up to the current step

46

4.3.5 Volume expelled in the current step

51

4.3.6 Getting the 'instantaneous' flow rate

51

4.3.7 Calculate the average, maximum and minimum flow rates

53

4.4 Assumptions

5. Validation of the Blister Model

5.1 MeasurementSetupfor Blister Dimensions

53

55

55

5.1.2 Selection of Hardware

55

5.1.3 Selection of Software

56

5.1.3.1 Gauge Repeatability and Reproducibility

57

5.2 MeasurementSetupfor Blister Flow

58

5.3 Validation of Blister Numerical Model

58

6. Monte Carlo Analysis and Regression Models

61

6.1 Manufacturing Variation Data

61

6.2 Monte CarloAlgorithm

62

7. Results and Discussion

63

7.1 Flow Rate Variation after considering only BlisterDimensional Variation

63

7.2 Flow Rate Variation after considering the variation in all dimensions

65

7.3 Regression on the Average Flow Rate

67

7.4 Regression on the Range of Flow Rates

68

7.5 Effect of Variation in Individual Dimensions on Flow Rate

69

7.5.2 Effect of Spherical Radius Variation

69

7.5.3 Effect of Blister Height Variation

70

7.5.4 Effect of Actuator Radius Variation

71

7.5.5 Effect of Starting Height Variation

72

7.6 Flow Rate Variation after consideringthe effect ofshimming

73

8. Conclusions and Recommendations

75

9. Future Work

77

9.1 BlisterModel Validation

77

9.2 Study of Dimensional Variation in Blisters

77

9.3 Increasing the Number of Runs in the Monte Carlo Simulation

77

9.4 Electrode Foils - ConfigurationStudy and ProcessAnalysis

77

9.5 FunctionalizationProcessOptimization

78

9.6 Injection Molding of the Backbone - Normalization Time Optimization

78

9.7 Valve-Solenoid Interaction Robustness Study

78

9.8 Effect of Imprecise Actuator Movement

78

References

81

10

List of Figures

Figure 1: Daktari Diagnostics CD4 Cell Counting Platform

19

Figure 2: The Daktari cartridge - with parts marked

20

Figure 3: The Daktari instrument - with parts marked

21

Figure 4. Assay Process Diagram

28

Figure 5. Microfluidic Device Architecture

29

Figure 6. Functionalization Process

33

Figure 7: Schematic of Metrology System using Machine Vision

35

Figure 8: Photograph of a Blister Pack (above) and Actuators (below)

37

Figure 9: Blister actuation process

38

Figure 10: Required Outputs from a Mathematical Model of the Blister

39

Figure 11: Particular blister dimensions that affect the flow rate

40

Figure 12: Flowchart of Blister Numerical Model

42

Figure 13: Effect of small step size on flow rate measurement

43

Figure 14: Effect of large step size on flow rate measurement

44

Figure 15: Introducing the effect of actuator misalignment and step size

44

Figure 16: Usage of transformation matrices to convert actuator coordinates to the blister coordinate system

45

Figure 17: Discrete Volume Calculation

46

Figure 18: Flowchart for Blister Volume Calculation

47

Figure 19: Intersection of Actuator and Blister at a particular height

48

Figure 20: Possible Scenarios when a Blister and Actuator Intersect

49

Figure 21: Calculating the area of a Circle-Circle Intersection

50

Figure 22: Volume Expelled in the Current Step

51

Figure 23: Total Volume Expelled vs. Crush Depth

52

Figure 24: Time taken for a Step versus the Crush Depth

53

Figure 25: Schematic of Blister & Camera Setup

55

Figure 26: Photograph of Blister Measurement Setup

56

Figure 27: Photographs of the Blister Using the Current Setup

56

Figure 28: Blister diameter (in no. of pixels) measured by 2 operators

57

Figure 29: Blister Height (in no. of pixels) measured by 2 operators

57

Figure 30: Plot of Experimental and Predicted Flow Rates from 5 Blisters

59

Figure 31: Flowchart of the Monte Carlo Algorithm

62

Figure 32: Distribution of Flow Rates considering only Blister Variation

64

Figure 33: Distribution of Flow Rates considering variation in all dimensions

66

Figure 34: Flow Rate Profile with a Smaller Spherical Radius

69

Figure 35: Flow Rate Profile with a Larger Spherical Radius

70

Figure 36: Flow Rate Profile with a Smaller Blister Height

70

Figure 37: Flow Rate Profile with a Larger Blister Height

71

Figure 38: Flow Rate Profile with a Smaller Actuator Radius

71

Figure 39:Flow Rate Profile with a Larger Actuator Radius

72

Figure 40: Flow Rate Profile with Lower Actuator Starting Height

72

Figure 41: Flow Rate Profile with Higher Actuator Starting Height

73

Figure 42: Distribution of Flow Rates considering the effect of shimming

74

List of Tables

Table 1: Product Development timeline

22

Table 2: List of Potential Cartridge-Instrument Interaction Issues

25

Table 3: List of Potential Issues during Ramp-up

26

Table 5: Variation Data for the Blister and Actuator Dimensions

61

Table 6: Summary of Output Distribution Properties considering the variation in blister dimensions alone63

Table 7: Increase in Percentage of Non-conforming Blisters with tighter tolerance ranges

65

Table 8: Summary of Output Distribution Properties considering the variation in all relevant dimensions 67

Table 9: Increase in Percentage of Non-conforming Blister-Actuator Systems with tighter tolerance ranges

67

Table 10: List of Coefficients for Linear Regression on Average Flow Rate

68

Table 11: List of Coefficients for Linear Regression on Range of Flow Rates

68

Table 12: Summary of Output Distribution properties considering the variation in all relevant dimensions73

Table 13: Percentage of Non-conforming Blister-Actuator Systems after shimming

74

14

1. Introduction

The field of microfluidics has been the subject of several decades of research. As a sub-field of

MEMS/MST (Micro Electromechanical Systems/ Microsystems Technology), microfluidics

promises the integration of various liquid preparation/processing steps along with the sensors

(optical, electronic or otherwise) that enable the complete analysis of samples. These so-called

labs-on-a-chip (LOC) have the potential to revolutionize any application where the analysis or

use of small quantities of fluid is useful. Some of these applications include immunoassays,

pharmaceutical drug discovery, genomics and proteomics, cytology and biotechnology, drug

delivery and surface patterning [1].

Despite this immense potential, till date, the commercial impact of the field has been minimal [1].

This may be attributed to several factors: the absence of commercial needs, low understanding of

fabrication technology and the lack of expertise in microfluidic product industrialization.

However, the situation appears to be changing.

Point-of-care (POC) diagnostics has recently emerged as an ideal market for LOC technology.

Currently, most diagnostic tests are performed in centralized laboratories which account for

around 60% of the 2004 market revenue [2]. Another 30% of the market is commanded by POC

diagnostics but these are almost exclusively for glucose-monitoring. For a number of other

pressing problems such as HIV, TB and malaria, POC solutions are practically non-existent.

Microfluidic technology can make these solutions possible [3].

The size of the problems that these diseases pose can be understood by the sheer number of

people affected by them. HIV affects nearly 33 million people worldwide [4]. TB affects another

9.4 million causing around 1.3 million deaths [5]. Nearly 300-500 million people are infected

with malaria [6]. For all these infectious diseases, POC diagnostics promises to decrease the time

between the first visit to the doctor and the beginning of treatment [7]. In many situations, this

can lead to improved health outcomes. For example, for HIV patients on anti-retroviral therapy

(ART) a key test, called the CD4 count, is used to monitor their immune system [8]. Recent

efforts to scale ART in developing countries quickly highlighted the CD4 test as a significant

bottleneck. POC promises to relieve this problem.

Keeping pace with the growing interest in LOC, is the constantly increasing understanding of

microfluidic fabrication technology. A great deal of work has been done [9-13] to better

understand and optimize these processes. Several organizations (e.g.: Inverness, Abbott Point of

Care, Daktari Diagnostics, Claros, Diagnostics 4 All) are taking advantage of these developments

and are actively involved in the POC equipment field. Thus, there is a growing interest in the

process of microfluidic product industrialization.

As a new entrant in the medical device space, Daktari Diagnostics (hereafter referred to as

Daktari) is currently involved in the process of product industrialization. A number of issues

related to reliable production of their microfluidic product are being addressed during this phase.

Some of these issues are: product tolerance analyses, design for manufacture and assembly

(DFMA) and identification of critical-to-function paths.

In this thesis, the manufacturability of one component of the Daktari LOC system - the 'blister

pack' - has been studied extensively. The blister pack is responsible for storing liquid reagents in

the product and then delivering these at a controlled flow rate. Its performance is affected in

many ways by manufacturing variation and this effect was fully explored. Numerical models

relating blister performance to their dimensions were developed and key input parameters that

must be controlled to ensure good performance were identified.

1.1 The M.Eng. Capstone Project

This thesis is the result of a group project that has been completed as part of the requirements of

the Masters of Engineering in Manufacturing program at the Laboratory for Manufacturing and

Productivity (LMP) at MIT.

A team of students approached the research problems

collaboratively and then each team member focused on a different research challenge. The author

of this work, Sivesh Selvakumar, focused on blister manufacturing issues. Rodrigo Linares [14]

focused on instrument manufacturing issues. Together, the two theses represent the complete

analysis of the problem of microfluidic device tolerance analysis.

1.2 Overview of the Thesis

This thesis begins with a description of the company, product and problem statement in Chapter

2. This is followed by a comprehensive literature review of the state-of-the-art in microfluidic

fabrication technology and assembly strategies in Chapter 3. Chapter 4 presents the development

of a numerical model that relates the geometry of the 'blister pack' to its flow performance.

Efforts to validate this model are presented in Chapter 5. Chapter 6 describes the methodology of

Monte Carlo simulations used to study the effect of manufacturing variation on the blisters. The

results of these simulations along with suitable conclusions are presented in Chapter 7. Our

recommendations for future work follows in Chapter 8.

18

.....

..................

...

.....................

................

2. Product and Project Overview

2.1 Company Background

Daktari Diagnostics is a medical diagnostic company located in Cambridge, Massachusetts, USA

that utilizes unique technology for various high-impact diagnostic applications. The company has

dedicated its product line to various diagnostic tests that will have a strong positive effect on

global health. Their first product is a point-of-care diagnostic platform for HIV patients. The

product is designed to be easy-to-use, robust and inexpensive - suited to developing countries

where this test is a major bottleneck to effective delivery.

2.2 Product Description

The diagnostic platform that is being designed by Daktari Diagnostics is a CD4 counter that is

necessary for HIV patients. Similar to a glucometer (which provides patients suffering from

diabetes with a value of their blood glucose concentration), the CD4 counter provides caregivers

with the white blood cell concentration in an HIV patient's blood. This value indicates the

relative strength of the patient's immune system and can be used to determine the appropriate

dosage and strength of anti-retroviral drugs (ARV). Figure 1 shows the process that goes into a

CD4+ T-Cell count using Daktari's System.

1.Blood is introduced to

disposable, which is

inserted into instrument

2. CD4 cells are captured

chermicaly, without sample

preparation

Cartridge

3. CD4 cells are detected and

counted electrochenically,

without optics or labels

Instrument

Figure 1: Daktari Diagnostics CD4 Cell Counting Platform

The typical use scenario involves a trained operator carrying the portable 'instrument' and a set of

'cartridges' to remote locations where the test is unavailable in its current form. Using a lancet,

the operator pricks the patient's finger and allows the patient's blood to enter the card at a sample

entry port. The card draws the blood in by means of capillary action. After sufficient blood is

drawn in, the sample entry port is closed using a cap and the card is loaded into the instrument.

The instrument begins driving the blisters in a carefully designed sequence of operations that

prepares the blood sample and then sends it through the assay chamber. The antibodies deposited

on the channel capture the CD4 cells. The cells are then lysed ('lysis' refers to the rupture of a

cell's membrane) in a high-impedance solution. This releases low-impedance cellular contents

into the assay chamber. The difference in impedance at this stage is used to determine the

concentration of cells in the blood [15]. The CD4+ cell concentration value is then displayed

using an LCD display and the test concludes.

The platform consists of two parts: an instrument and several disposable cartridges.

2.2.1 The Cartridge

Each cartridge is a disposable microfluidic device complete with reagents and a sensing

mechanism to measure the concentration of CD4 cells in blood. Figure 2 depicts a prototype of

the microfluidic card with the following 6 parts:

Housing

Blister

Cap

Backbone with microfluidic channels

Lid foil on the back

Electrode Foil

Figure 2: The Daktari cartridge - with parts marked

1. Backbone - an injection molded polymer card with microfluidic channels

ck

. ....

....

....

.. .

.

... ............

......

........

2. Lidfoil - a transparent polymeric sheet that is bonded to one side of the backbone and

forms the fourth wall of the channels

3. Functionalizedfoil- a polymeric foil that covers the 'assay chamber' where the CD4

cell count is performed. This foil has a gold electrode layer formed on it. It is then coated

with antibody solution, which is used to immobilize the target CD4 cells.

4. Blisterpack - similar to a pharmaceutical blister pack, this part contains the liquid

reagents that are necessary for sample preparation

5. Housing - an injection molded polymer part that protects the blister pack and

functionalized foil during transport

6. Cap - plastic part that covers the sample entry port after blood is introduced into the

cartridge

2.2.2 The Instrument

The instrument is designed to be portable, battery-powered and electronically controlled. It

contains linear actuators to 'pop' the blisters and flow reagent through the cartridge's channels.

Figure 3 shows a photograph of the instrument.

Handle for holdin the device

Figure 3: The Daktari instrument - with parts marked

The instrument also has suitable electronic interfaces, which connect to the cartridge and measure

the impedance within the assay chamber. This impedance measurement is used to determine the

final level of CD4 cells within the device. In addition, the electronics necessary to drive the

actuators, calculate the CD4 count and output this value to the LCD display are also present. The

instrument is both the driver of the reagents and the user interface medium between the system

and the user. In order to accomplish all these functions, the proper integration of the following

subassemblies must be accomplished.

1. Frame - the main structural component of the instrument. It locates the different

subassemblies.

2. Door Subassembly - holds the cartridge in place and guarantees planarity between the

cartridge and theframe.

3. Actuator Subassembly - carries the actuators and ensures perpendicularity between these

and theframe.

4. Solenoid Subassembly - supports the valve solenoids and ensures perpendicularity

between the solenoids and theframe.

5. Outer Casing - provides both aesthetics and protection from impacts and dust.

2.2.3 Product Timeline

Table 1 below depicts the high-level view of the product development timeline for Daktari. It

involves the development of two prototypes (gamma and alpha) that will be used to solve various

anticipated issues. The final one i.e. beta will be the first production-level product. This thesis

focuses on issues related largely to the alpha and beta stages.

Table 1: Product Development timeline

Purpose

Production Quantities of:

a) Cartridges

a) Instruments

Proof-ofconcept for

investors

1

1

Run clinical

trials and

establish the

reliability and

repeatability

of the test

1000s

10s

First

production

product

350,000 (per year)

150 (approx.)

2.3 Problem Statement

As Daktari moves from prototype to production i.e. alpha to beta, a number of issues will need to

be addressed in order to ensure reliable, cost-effective production. Typically, the effect of

manufacturing variation on the functionality of the proposed design must be understood. With

this knowledge, a range of design parameters may be optimized leading to a more robust design.

In some situations a conflict between design requirements and inherent manufacturing limitations

may arise. In this case, suitable quality control strategies must be provided.

All of these activities -both experimental and analytical - are commonly grouped together under

the umbrella term 'product industrialization'. The absence of such a step often leads to bad

designs which, when put into production, lead to poor quality, wasteful processes, high

production cost and long lead times. Thus, it becomes important to understand that a good

product is one that not only performs its intended function when 'perfect' but is also easy to

manufacture, easy to assemble and, hence, economical to produce.

The aim of this M.Eng. project is to analyze and propose solutions for issues related to the

mechanical robustness of the Daktari system. Accordingly, a survey was first done to list all

issues that will require attention en route to mass production.

2.3.1 Survey of Manufacturing Issues

The Daktari POC system uses a number of components that have not been used extensively

previously and so several areas require further study:

a. The Electrode Foil Manufacturing process

The electrode foils on the cartridge are critical to the sensing process of the LOC system.

Preliminary studies indicate that repeatability of the impedance measurement can be strongly

related to the exact electrode configuration and manufacturing defects. Further study is required

to understand this phenomenon and ensure repeatability.

b. Functionalization process

The functionalization process refers to the process of depositing antibody solution on the

electrode foil (see Section 3.4.2 for detailed description) . This process is again critical to the

success of the assay because improperly coated antibody can result in several problems:

* improper bonding between the electrode foil and the backbone leading to leaks

* variability in the number of CD4+ cells captured by the system leading to low repeatability

in results

c. Injection Molding of the Backbone

The injection molding process of microfluidic devices often requires very large normalization

times - the time required for the plastic to reach its final dimensions - often in the order of days.

Any downstream processing that affects normalization process or requires the dimensions that are

affected by it cannot be performed until the normalization is complete. This results in long lead

times which could be a potential issue in manufacturing. (resulting in large inventories and

associated storage costs)

Although, this issue could have a large impact on the manufacturing cost of the final product,

currently it does not seem to be critical to the product functionality.

d. Robustness of Instrument- Cartridge Interactions

i) Blister - Actuator Interaction

The interaction between the blister and the actuator produces the required flow in the final device.

Precise movement of a precision-machined actuator ensures controlled flow. However, the

amount of control obtained based on current design specifications and manufacturing variation is

unknown and should be studied to confirm flow rate tolerances.

ii) Valve - Solenoid Interaction

The valve and the solenoid together ensure control over the direction of fluid flow within the

cartridge. This is important as leaking valves (valves that are open when they should be closed)

and 'sticky' valves (valves that are closed when they should be open) can seriously affect assay

performance. A tolerance analysis of this step should be performed to determine the effect of

misalignment.

iii) Vent hole - Puncture Pin Alignment

The vent hole is a weak portion of the backbone that is designed to be opened by a pin in the

instrument. This is necessary to open the system to the environment allowing fluids to be run

through without causing air compression. Failure to open the vent hole can be critical to product

success as it may become nearly impossible for the actuators to pump fluid through the system.

iv) Electrode Gold Pads - Electric Connector Interface

The electrical connection between the electrode foil and the instrument is critical to the reading

the results of the assay. A failed connection will prevent impedance measurements from being

taken. However, this connection also has much tolerance built into it and it is not believed that it

will cause much problem.

The above cartridge-instrument interaction issues are summarized in Table 2.

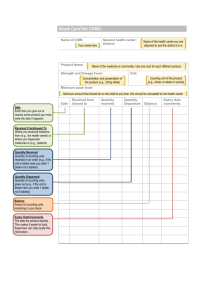

Table 2: List of Potential Cartridge-Instrument Interaction Issues

Interface

Tolerable Variation

Approximate Manufacturing

Variation

Blister - Actuator

Unknown

Several mm

Valve - Solenoid

Unknown

Several mm

Vent Hole - Puncture Pin

0.5 mm (radial)

Several mm

Electrode Contact Pad -

+/- 1 mm

Several mm

Instrument Electrical Connector

2.3.2 Selection of Subset of Problems

Table 3 displays a list of the above issues along with a note about their importance (for product

function) and likelihood of occurrence. From this list, issues related mainly to the mechanical

robustness of the device were selected. These were all the issues under sub-section 'd'.

Table 3: List of Potential Issues during Ramp-up

Importance for

Product Function

Likelihood of

Occurrence

a. Electrode Foil Manufacturing

High

High

b. Functionalization

High

High

c. Injection Molding of backbone

Low

Low

i) blister-actuator

Medium

Medium

ii) valve-solenoid

Medium

Medium

High

Low

Issue

d. Robustness of Interactions

iii) vent hole -puncture pin

iv) electrode contactpatch

- instrument contactpins

High

Low

It was proposed that a detailed tolerance analysis of the entire system be performed to determine

the overall stack-up of manufacturing variation on the various interfaces. In addition, the

influence of this variation on the performance of the interfaces would be studied to determine

their effect.

In particular, greater focus was to be placed on the blister-actuator interface. A numerical model

relating blister performance to the dimensional variations was developed in this thesis and this

model was used in conjunction with the tolerance analysis of the entire system developed by

Linares [14]. Linares [14] also performed the tolerance analysis for the remaining interfaces. This

study would lead to a better understanding of the interfaces and permit the suggestion of suitable

solutions for optimizing the designs.

3. Background Research

Initial research focused on understanding the applications of microfluidics (Section 3.1) and,

thereafter, on studying the state-of-the-art in microfluidic device architecture (Section 3.2),

components (Section 3.3) and manufacturing processes (Section 3.3). This was done in order to

fully understand the interactions between this study on robustness and the design and

manufacturing of Daktari's microfluidic device.

After this preliminary research, the tools and techniques used in this thesis were explored. This

includes the technique of Monte Carlo simulations used for variation analysis and the use of

machine vision for metrology.

3.1 Lab-on-a-Chip Applications

An extensive survey was done by Korb [1] on the various potential applications of microfluidics.

It quickly became apparent that most applications were in biochemistry and related fields. The

applications can be grouped as: assays, drug discovery, genomics and proteonomics, cytology and

biotechnology, drug delivery and surface patterning.

The CD4+ sensing system falls into the cytology and assay category. In cytology, microfluidics is

used to sort cells and select ones of interest. In assays, the presence or concentration of a

substance is determined. For example, the purpose of Daktari's microfluidic device is to perform

an assay on a fixed volume of blood and determine the concentration of CD4+ cells.

3.1.1 CD4+ Cell counting through Cell Lysate Impedance Spectroscopy

This is the technique used by Daktari in its CD4+ Cell Counter System. In this method (see

Figure 4), cells are first immobilized by the use of cell affinity chromatography [16]. Then, the

cells are lysed, and a drop in impedance is produced due to the different electrical properties of

the cellular contents. The change in impedance is measured using the electrode foil. It is

converted to a change in conductance. The magnitude of this change increases linearly with the

number of immobilized cells [15]. These methods showed a close correlation between the CD4

cell counts when comparing the microfluidic device and flow cytometry [17].

ya

F1'i

Y

+ CC

Y

Antibody

Red Blood Cell

CD4+ Cel

Figure 4. Assay Process Diagram. (A) Blood is ran through the assay chamber and CD4+

cells are captured. (B) Red blood cells are washed. (C) CD4+ cells are lysed and difference

on impedance is measured.

3.2 Microfluidic Device Architecture

The architecture of microfluidic devices is similar to that of Printed Circuit Boards (PCB). These

devices are formed by different layers each performing a specific function. Figure 4 shows a

typical arrangement consisting of one or more central layers (backbone) where open micro

channels are formed (usually with 2.5D features) and one or two external layers to close the

channels. Additionally external connections, valves, pumps and sensors are often added.

............

. . ..

..

.........

.......

Additional Component

Central Layer

External Layer

Figure 5. Microfluidic Device Architecture

3.2.1 Central Layer

This layer is often the functional part. All the features, such as microchannels, mixers, reservoirs

and other components are formed in this layer. Its complexity varies from a simple piping

system to a complex set of mechanisms.

3.2.2 External Layer

Its purpose is usually to close the channels and features on the central layer. Additionally

functionality is often added to this layer using PCBs, sensors and outputs from other systems.

3.2.3 Additional Components

In addition to the above, microfluidic devices typically contain other components that perform

external flow control, internal flow control and sensing.

ExternalFlow Controlmechanisms are added to provide an external means of delivering reagents

into the Lab-on-a-Chip (LOC). The work involved in pumping arises from non-microfluidic

interactions. Some examples are external reservoirs (where the column of liquids drives the

fluids), actuators ( which push liquid-filled blisters), external valve systems and syringe pumps.

InternalFlow Controlcomponents fulfill the same purpose as those placed externally. However,

flow arises due to interactions with microfluidic features. Examples include peristaltic or pressure

driven pumps, valves, mixers, separators, reactors, etc.

Sensing components are often put into place on the external layers of the device. Commonly

these are used to measure pressure, temperature or electrical properties (impedance, capacitance,

etc.). Additionally, much attention has been focused on optical sensing systems.

3.3 Lab On a Chip Technologies

For a microfluidic device to perform any particular function, whether that be an immunoassay or

genome sequencing, several proven technologies are currently available to the engineer or

researcher that can be used as tools or components to achieve their goals. Among them we have

microfilters, microneedles, micromixers, microreactors, microdispensers and microseparators.

Nguyen [18] provides a very good description of these technologies and its applications in life

sciences.

Microfilters are used for either filtration or collection depending on whether the substance of

interest is a liquid that is contaminated by particles or the particles themselves. Both of these

functions are achieved through the use of membranes or gaps built into the microfluidic piping

system.

Microneedles are used for drug delivery, cell manipulation and interconnection between micro

and macrofluidic systems.

Micromixers combine two or more reagents to make a reaction possible. The advantage of this

technique lies in the efficient use of reagents. The key difference between macro and micro scale

is the mechanism of mixing - macroscale mixing uses turbulence whereas microscale mixing

depends on much slower diffusion processes on account of the low Reynolds' number in

microfluidic channels.

Microreactorsaccomplish the same tasks as their macroscopic counter parts, but with several

advantages. The reactions are easier to control, reducing the danger of an explosion or fire.

Additionally if dangerous substances are released, they are easily contained. They offer a cost

advantage both in manufacturing and in their operation. They are easy to scale from laboratory to

commercial applications. Finally they offer small thermal inertia, high gradients, uniform

temperature, short residence time and high surface to volume ratio.

Microdispensersprovide precise reagent delivery. Examples include microscopic injectors,

pipettes or dosing systems.

Microseparatorsprovide substance or particle separation. Microfilters can be considered as a

category of microseparator that discriminate by particle size and geometry. Microseparators take

advantage of difference on weight, electrical, magnetic or thermal properties.

3.4 Lab-on-a-Chip Manufacturing Processes

Each of the parts of the microfluidic device architecture can be produced using a multitude of

processes. In the literature, most attention has been given to the central layer manufacturing

process because all the functional features are often built into this layer.

Additionally, and equally important, are the processes for assembly of the several layers. These

processes involve alignment, placement and binding.

The materials in which the devices are made greatly influence the process in which it is

constructed. The most common material used for LOCs are glass, polydimethylsiloxane (PDMS)

and polymethylmethacrylate (PMMA). Glass and PDMS are commonly used in laboratories since

fast and precise prototyping techniques exist that allow researchers to iterate rapidly between

different designs. Many of the techniques used in the semiconductor industry are borrowed to

achieve nano-scale features. Also, many components of LOCs (e.g.: some kinds of valves and

pumps) are only achievable on PDMS since they take advantage of the material's elastic

properties.

PMMA presents bigger difficulties for prototyping. Tooling fabrication is required, thus

increasing the turnaround time. Nevertheless, since the 2000s there has been a growing consensus

on the use of polymeric materials for microfluidic commercial applications [12]. Attia et al [13]

performed a useful comparison between the different materials used on microfluidic devices.

3.4.1 Part Manufacturing

Korb [1] also performed a detailed survey on the manufacturing processes currently in use and

their advantages and drawbacks. For central layer manufacturing, two methods were considered

for this work due to their high throughput - injection molding and micro embossing. For external

layer manufacturing, typical processes include rolling, molding and extrusion of thermoplastics.

Injection molding is a well-known manufacturing method that can be used to produce complex

forms out of thermoplastics. There have been successful attempts to replicate square features with

a width of 310 nm and depth of 220 nm [19]. It is highly suited to large scale manufacturing due

to its dimensional control, short cycle times and high throughput. The challenge of bringing this

technique to the micro scale lies in tooling construction. To the author's knowledge, injection

molded microfluidic parts have been limited to having 2.5 D features.

Micro-embossing involves raising the temperature of a blank polymer piece beyond its

crystallization point followed by pressure to transfer features from a tool to the blank. The

process has been shown to allow nanometer scale features [12] with high accuracy and precision.

Its primary advantage over injection molding is in lower tooling costs and potentially lower cycle

time. However, the process is limited in the complexity of features that can be created. Also,

when an embossed part is subjected to high temperatures in subsequent operations (such as

thermal bonding) the surface stresses tend to relax leading to a softening of the features.

Overall, the use of injection molding appears to be preferred to the greater flexibility and the

fewer manufacturing steps.

3.4.2 Functionalization Process

Functionalization refers to the deposition of antibody on one or more parts of the product. The

process is not well-understood and successful applications tend to be based on empirical

experience rather than an actual understanding of the phenomena that take place.

Antibodies can be deposited onto solid phases by three different mechanisms [20]:

1. Adsorption to hydrophobic surfaces

2.

Covalent attachment to activated surface groups

3. Non-covalent, electrostatic and hydrophilic bonds by either of the before mentioned.

It is a requirement for Daktari that the antibody be deposited in a specific area of the electrode

foil. Currently, this is accomplished using a masking process. The mask is placed on the electrode

and the open cavities in the mask are filled with antibody solution. After a certain amount of time

(termed 'incubation' time), the antibody solution is removed and the foil is allowed to dry. This

multi-step process is illustrated in figure 6. Often, the antibody layer must be stabilized using a

sugar layer as well.

......

...

.......

1. Electrode Foil is covered with a mask

2. Antibody solution is added

3. Antibody is attached to Foil substrate

4. Excess solution is removed

5. Sugar solution is added

6. Sugar solution is dried

7. Mask is then removed

-Foi

Mask

Figure 6. Functionalization Process

3.5 Monte Carlo Analysis

Monte Carlo simulations are a technique for determining the parameters of an actual population

by taking random samples from a pseudo-population and then calculating statistics using that

sample. It involves the two steps of actually creating a pseudo-population of interest and then

sampling from this population so that various statistics may be calculated.

The Monte Carlo technique is widely used in situations where the behavior of the statistic does

not lend itself to straightforward analytical evaluation. In such cases, Monte Carlo analysis can

simulate the required sampling distributions allowing inferences to be made.

The basic steps involved in Monte Carlo analysis are as follows [21]:

1. The creation of a pseudo-population (usually a mathematical algorithm or model)

2. Sampling from the pseudo-population in a manner consistent with the real process

3. Calculate the value of the statistic from the sample

4. Repeat 1, 2 and 3 for 'n' trials

5. Plot a frequency distribution of the statistic which can then be used for inference

This technique has been used in several studies [22-25] regarding manufacturability and tolerance

analysis because of the complex nature of the interactions. In this thesis, Monte Carlo simulations

are used to determine the effect of random variations in dimensions on the flow rate of reagents

delivered by the blister packs.

3.6 Machine Vision for Metrology

3.6.1 Choice of Metrology System

In order to accurately and repeatably measure the blister dimensions, two options were

considered: using a coordinate measuring machine (CMM) and using an optical setup (a machine

vision system). The CMM had the advantage of being more accurate (order of microns) and not

requiring calibration. However, as the blister was a non-rigid part, and the CMM used a force

sensor attached to a probe to measure the dimensions, its effect on the blister dimensions was

unknown. As a result, the optical system was chosen. The optical system also had the advantage

of having a much lower measurement time per blister.

5.1.2 Components of a Machine Vision System

A machine vision system for measurement consists of two separate, yet inter-related, systems: the

hardware and the software. The hardware involves all the parts of the machine vision chain that

are responsible for producing a high-contrast, high-resolution image of the object that is being

measured [27].The software is responsible for analyzing the image and obtaining the required

dimensional information.

HARDWARE

SOFTWARE

Data Acquisition

Lighting

Camera

Computer

Oiage

Anasnis

Output Mecasurements

ObNect to be

Measured

Figure 7: Schematic of Metrology System using Machine Vision

The hardware includes fixtures for repeatably mounting the objects to be measured, appropriate

lighting that provides a suitable amount of contrast and a camera of sufficient resolution to

capture the image. The camera is essentially a combination of the image sensor and the optical

elements (lenses, mirrors, etc.) necessary to project the required part of the image onto it.

The software includes the interface between the data acquisition system and the camera, the

imageprocessing algorithms that enable suitable extraction of information and the final image

analysis algorithms for measuring dimensions.

4. Development of the Blister Performance Model

The blister performance model described in this section is used to relate the dimensions of the

blister to its performance as measured by certain metrics. The process of creating the model

began with an attempt at an analytical expression to model the working of the blister. However,

the complex nature of the actuator and blister interaction quickly complicated the analysis and

was abandoned in favor of a more practical approach using numerical integration.

4.1 Working of the Daktari Blister Pack

Figure 8: Photograph of a Blister Pack (above) and Actuators (below)

The blister pack (Figure 8) is that part of the cartridge which is used to store the liquid reagents

used in the assay. It is similar to a blister pack that is used to store pharmaceutical tablets/capsules

and is manufactured using a similar cold forming process. Figure 9 depicts the blister pack in

action. An actuator is allowed to push down the blister until the seal breaks. Further movement

causes the liquid reagent to flow into the micro-channels on the backbone. Controlled actuation

should enable a constant flow rate through the micro-channels. The constancy of thisflow rate is

the most important performance measure of the blister pack.

I

V

I

ACrUATOR

BLISTER

1.The actuator begins

2. The actuator moves

down towards the

bhster with reagent

at the 'home' position

3. The actuator comes

into contact with the

blister

(shown in blue)

i

t

5. The actuator

6. As the actuator

continues to move

moves down, it slows

downwards forcing

reagent out of the

blister

down maintaining the

same flow rate

4

4. The actuator moves

down approximately

2.5mm to break the

blister seal (in red)

7.The actuator stops

moving when 184)

micro liters of reagent

flow out

Figure 9: Blister actuation process

For Daktari's current application, a tolerance of +/- 20% on the flow rate is believed to be

acceptable. For example, for a nominal flow of 20 pL/min, an actual flow rate that ranges

between 16 and 24pL/min is satisfactory. In order to maintain this constant flow rate, the speed of

the actuator is decreased as it moves down, in order to compensate for the increase in crosssectional area (Since, volume flow rate = linear velocity * cross-sectional area). Very precise

actuation is necessary to maintain a smooth flow and, to the knowledge of the author, such a

procedure has not been studied till date.

4.2 Requirements of the Blister Numerical Model

The blister model should be capable of sufficiently re-creating the working scenario described in

the previous section. Taking the actual dimensions of the blister and actuator as input, the model

should be able to give the flow rate of the fluid as a function of the position of the actuator (See

Figure 10).

Depth

Cru

A = B

= Total Volumc Expcllcd

A

at crush dcpth

a6 .E

E

Crush Depth

(mm)

Figure 10: Required Outputs from a Mathematical Model of the Blister

In addition, for purposes of studying the effect of manufacturing variation on the blister

performance, the model should include the continuously varying speed of the actuator as it

plunges into the blister.

y Y6 ;44Y!,! "

4.2.1 Blister Outputs and Noise Factors

The total volume of fluid required from each blister is 180pL. As the actuator tip plunges into the

blister, this 180pL of reagent should be expelled at a constant flow. Thus, the function of the

blister can be captured by the following two metrics:

1. Average flow rate: This captures the mean value of the flow rate.

2. Maximum of flow rate: This gives the upper bound of the flow rate due to nonconstancy of flow

3. Minimum of flow rate: This gives the lower bound of the flow rate due to nonconstancy of flow

The above metrics are depicted in Figure 10. The various variables, which affect the flow rate of

reagents in the channels, are as follows:

1. Base Radius

2. Spherical Radius

3. Blister height

4. Lateral Misalignment

5. Angular Misalignment

6. Actuator Radius

7. Actuator's Starting Height (i.e. initial position of the actuator above the blister)

Figure 11 depicts variable 1 -3 of the above list. These are related to the blister pack production

process while 5-7 are related to the instrument manufacture. Variable 4 is related to both. For the

purposes of this analysis, variables 1 through 4 are taken as noise factors.

0

Blister Radius

Figure 11: Particular blister dimensions that affect the flow rate

---

4.3 The Numerical Model

The numerical model is based on the use of numerical integrationto calculate the volume of the

blister at each step of the actuator. The motion of the actuator was discretized i.e. each step

movement of the actuator was associated with a particular amount of time. The blister itself was

divided into a set of discrete volume elements and its volume calculated at each step to determine

the volume of fluid expelled. Figure 12 is the flowchart of operations that must be performed by

the blister model. Each step is further discussed in the following sections.

START

Input Blister and

Actuator Dimensions

and Positions

Calculate TOTAL VOLUME

EXPELLED up to the current

step

Input Speed of Travel

LSet

Calculating VOLUME

EXPELLED IN CURRENT

STEP by subtracting the total

volume expelled up to the

previous step

Step Size =0.1mm

Determine all ACTUATOR

POSITIONS using

transformation matrices

Have all steps

been

completed?

Calculate INSTA NTANEOUS

FLOW RATE b y dividing the

volume expelle d by the time

taken by the actuator to

complete the step

No

A

Yes

Calculate the AVERAGE,

MAXIMUM AND

MINIMUM FLOW RATE

Output the above flow

rates

STOP

Figure 12: Flowchart of Blister Numerical Model

4.3.1 Input Blister Dimensions and Speed of Travel

The blister and actuator dimensions listed in Section 4.2.1 are provided to the mathematical

model in this step in order to re-create the geometric shape of the blister. The required flow rate

(5iL/min or 20RL/min based on the application) is also provided at this stage so that the

appropriate actuator movement curve is chosen.

4.3.2 Step Size

The 'step size' refers to the distance the actuator 'moves' during each step of the blister model.

By comparing Figure 13 and Figure 14, the effect of having large step sizes can be seenvariations in flow rate which are actually present can get smoothened out by averaging over a

larger range of movement. Thus, smaller values of the step size lead to better approximations of

the actuator movement at the cost of increased computation time. An optimal step value was

chosen based on trial and error.

Volume Expelled per unit time

(uL min)

Au

13

Figure 13: Effect of small step size on flow rate measurement

Volume Expeled per unit time

Af-

06

"

Figure 14: Effect of large step size on flow rate measurement

4.3.3 Determine ActuatorPositions accordingto Step Size and Misalignment

X

X

YA

The actuator position is based on an ideal

blister and so crush depth is always

measured downwards from the actuator axis

(in blue)

in order to account for the errors, the

actuator is given an initial position and

angular misalignment from the vertical

Figure 15: Introducing the effect of actuator misalignment and step size

In the physical system, the absence of a feedback loop to control actuator position could lead to

problems due to misalignments (shown in Figure 15). In order to study the effect of the

misalignments, they were included as inputs to the blister model at this stage. Both lateral and

angular misalignments were included using a set of transformation matrices (see Figure 16) to set

the initial position and angular misalignment separately. These matrices convert the unidirectional

movement of the actuator into a 2D movement in real space.

B

B

*Tab

UL.~

*

X

Tac

Tac transforms the

coordinate system C to the

blister coordinate system A

The product of Tac and

Tcb gives Tab which

transforms the actuator

coordinate system (B) to

the blister coordinate

system (A)

'-

Teb

Tcb transforms the

coordinate system from the

actuator (B in blue) to the

coordinate system C

Figure 16: Usage of transformation matrices to convert actuator coordinates to the blister

coordinate system

Here, Teb is the angular transformation matrix that re-orients the actuator coordinate system in the

same direction as the blister coordinate system. Then, it gets re-positioned to the blister

coordinate system by means of Tac, a positional transformation matrix.

1I

1mO

Tc = 0

0

HO

1]

T

=

cos 6

sin 6

-sin 6

cos 6

0

0

.. ...

.....

Thus, any coordinate in the actuator coordinate system (0,Actuator Depth), can be converted to

the blister coordinate system as follows:

Y = TIC * T, * (Actuator Depth

The (x,y) coordinates of the actuator center obtained using the above expression can be used to

calculate the total volume of fluid expelled.

4.3.4 Calculate the total volume offluid expelled up to the current step

ACTUATOR

BLIS7ERdV

=Common Area x dY

Figure 17: Discrete Volume Calculation

In this step, the volume of fluid expelled from the blister is calculated using the process of

numerical integration. As shown in Figure 17, the common volume between the blister and the

actuator is divided into discrete volumes and summed together to obtain the total volume. For

each volume slice, the common area between the two curves is determined and then multiplied by

the height of the volume slice.

The sequence of steps involved in the common volume calculation is shown in Figure 18.

Input Blister

and Actuator

DIMENSIONS

and

POSITIONS

Calculate BLISTER

RADIUS RI at the height

of the cross-section

Calculate ACTUATOR

RADIUS R2 at the height of

the cross-section

Calculate

COMMON

AREA using

only smaller

circle and

multiply by

dY to get dV

Calculate COMMON

AREA using circlecircle intersection

and multiply by dY to

get dV

Figure 18: Flowchart for Blister Volume Calculation

Provided the blister and actuator are present at a particular slice, the common area between the

two can be easily calculated by the procedure depicted below in Figure 19.

At a particular height, the intersection of

blister and actuator produces two

intersecting circles

The blister circle (in green) and the

actuator circle (in blue) intersect and the

common area represents the portion of

fluid expelled

The top view of the intersection shows

the common area (in yellow)

Figure 19: Intersection of Actuator and Blister at a particular height

There are 3 possible scenarios when the blister and actuator circles intersect:

1. The circles do not intersect

Figure 20(a) shows a situation wherein the two circles do not intersect. In this case, the common

area is zero and this volume slice does not contribute to the volume calculation.

iw - +m

_ _

Ar _

NMMMMMhF_

_::_:

RI +R2<d

RI+R2>d>R2-RI

d<R2-RI

Non- Intersecting Circles

(a)

Intersecting Circles

(b)

Circle within another circle

(c)

Figure 20: Possible Scenarios when a Blister and Actuator Intersect

2. The two circles intersect

Figure 20(b) shows a situation where the two circles intersect. The common area between the two

circles is calculated using a circle-circle intersection formula [26]

The horizontal distance between the points of intersection (P,Q) and the center of the smaller

circle 01 is denoted by 'x'.

d2

- R2

2

2d

+ R2

Key:

00,

RI

- Center-Center Distance, 'd'

- Radius of the Blister Circle

R2

- Radius of the Actuator Circle

Figure 21: Calculating the area of a Circle-Circle Intersection

The area of intersection between the two circles is obtained as the sum of the areas of the

asymmetric lenses (shown in blue and yellow in Figure 21) formed by the two circles.

Common Area = A1 + A2

where

d

2

A2 =dR2

cos-1(

-

x)

R2

x

-

(d-x) R2 2 - (d - x)2

3. One circle is entirely within another

Figure 20(c) depicts a situation wherein the smaller circle lies entirely within the larger. In this

case, the area of the smaller circle gives the common area between the actuator and blister at that

point.

This is calculated simply as:

Common Area= ;

R

4.3.5 Volume expelled in the current step

The volume calculated from the previous steps represents the crushed volume of the blister i.e.

the volume of fluid that has been expelled up to that point. From this step, the volume expelled

during any step can also be found simply by subtracting the total volume expelled up to the

current step (Figure 22).

Volume Expelled in Current Step

=

Total volume expelled up to current step

-

Total Volume Expelled

at Current Actuator Step

Total volume expelled up to previous step

Total Volume Expelled

at Previous Actuator Step

Volume Expelled

during the Current Step

Figure 22: Volume Expelled in the Current Step

4.3.6 Getting the 'instantaneous'flow rate

Once the volume expelled in a particular step is found, it is divided by the time taken by the

actuator to complete that step. This time depends on the position of the actuator and is calculated

so that an ideal actuator in contact with an ideal blister will produce constant flow.

ACTUATOR

Total Volume Expelled

(uL)

Crush

Depth

(mm)

BL ISTER

dH

Total Volume Expelled = f (Crush Depth)

Crush Depth

0 (mm)

dH - step size

dV - volume expelled in current step

Figure 23: Total Volume Expelled vs. Crush Depth

Figure 23 shows how the time taken for a given step is calculated from the ideal blister-actuator

interaction. For a particular step 'dH', the corresponding volume expelled is given by 'dV'. This

volume must be expelled in a certain period of time 'dt' such that the flow rate is a constant.

-,

V

dt

where V is the constant flow rate required

dt

=

dV

.

,

for that particular step dH corresponding to a particular crush depth 'H'

This value dt is determined for the entire range of movement of the actuator and plotted (Figure

24).

Using regression.

-t

dt=f (H)

Crush Depth (H)

Figure 24: Time taken for a Step versus the Crush Depth

A regression equation of dt vs crush depth is obtained from this graph and using this the time

taken for any step can be calculated.

Once the time dt is known, the instantaneous flow rate is calculated as:

InstantaneousFlow Rate =

Volume Expelled in CurrentStep (dV)

Time takenfor Step (dt)

4.3.7 Calculate the average, maximum and minimumflow rates

From the set of instantaneous flow rates obtained from the previous steps, the average as well as

extreme flow rates are determined. These metrics (as discussed in Section 4.2.1) are taken to be

representative of both the mean and non-constancy of the flow profile. These metrics once

calculated are the required outputs of the blister numerical model.

4.4 Assumptions

The following assumptions were made in the development of the blister flow rate model:

1.

The blister collapses regularly with no crumpling

This assumption greatly simplifies calculating the common volume between blister and

actuator. In situations where crumpling of the blister begins to occur, the uncertain nature of

crumpling leads to sudden increases in flow rate which are difficult to predict. It has been

shown experimentally (by Daktari) that the current blister and actuator shape do not cause

crumpling. However, this may not be the case for arbitrary shapes of blister and actuators. A

great deal of optimization may be required to arrive at a suitable configuration.

2.

There is no air in the blister

Air present in the blister tends to act like a damped spring (due to its viscosity and

compressibility). This could lead to large time constants before reaching stable flow. By

assuming the absence of air, these dynamic effect are taken to be absent and the liquid

responds instantaneously to changes in the velocity of the actuator.

3. Angular misalignments are measured about only a single axis.

This blister model makes the assumption that angular misalignment and lateral misalignment

occur in the same plane i.e. only 2d misalignments have been considered. While it is believed

that this is representative of the real system, a more accurate model would include another

angular misalignment in order to fully study the different modes of variation.

5. Validation of the Blister Model

Validation of the blister performance model developed in the previous section was attempted

using two setups: an optical setup for measuring the blister dimensions and an experimental setup

for measuring the flow output from the blisters. This data was correlated and compared to the

model predictions to determine the model accuracy.

5.1 Measurement Setup for Blister Dimensions

5.1.2 Selection of Hardware

Fixturing of a cartridge (containing a blister pack, see Figure 2) was accomplished by fixing the

plane of the cartridge on a base and thereafter locating using a 2-1 fixturing system. Figure 25

shows a schematic of the setup used. An interesting feature of this system is the ability to index

the 'blister locator'. This allows both top and side views of each blister to be photographed

without having to change the focus.

Top View

Side View

LiZUZ1

Blister

Locator

Top View

Side View

I-

0

Figure 25: Schematic of Blister & Camera Setup

The camera used for the photographs was a Fujifilm FinePix S700 with a Fujinon Zoom Lens (f=

6.3mm). Although the resolution of the camera was around 7.1 megapixels, the zoom lens

allowed a large portion of the image to be occupied by the blister increasing the number of pixels

devoted to it. Figure 26 is a photograph of the entire setup with camera and cartridge mounted.

Top View of the Setup

Thc blister locator is in position to

measure the side profile of the blisters

Front View of the Setup

The blister iocator is in position to

photograph the top view of the blisters

Figure 26: Photograph of Blister Measurement Setup

Calibration of the setup indicates that each pixel corresponds to a distance of 17.6 microns at the

focal plane. Using this setup highly repeatable photographs could be taken. Figure 27 shows some

examples.

Side -vicw of the blister pack showing

the height h)aand sphecmal raditus (r i

Iop iew of the bhter pack

shouing the base radius (R)

Figure 27: Photographs of the Blister Using the Current Setup

5.1.3 Selection of Software

Typically the software in a machine vision system, is expected to perform quick analysis of an

image and output the required dimensional information in a manufacturing line. However, for the

purposes of this project, time of measurement was not a significant constraint. Thus, instead of

using image processing algorithms to extract features from a captured image, it was decided to

manually count the number of pixels associated with each dimension. Although, this process is

time consuming and should be avoided for higher number of tests and higher repeatability, it has

been adopted in order to minimize the time required to setup the image processing algorithms. In

order to determine the repeatability of manual measurements, a gauge repeatability and

reproducibility (R&R) experiment was performed

5.1.3.1 Gauge Repeatability and Reproducibility

The repeatability of image manipulation and the entire measurement setup were measured in two

separate steps. For the repeatability of image manipulation, the same images of a blister were

measured 5 times by 2 operators. The results are shown in Figure 28 and Figure 29.

Blister Diameter from Top View

522

$21

520

519

518

517

Sib

* 521

£ 5-20

4

ft-i

$20

* 516

1

Operator No.

Figure 28: Blister diameter (in no. of pixels) measured by 2 operators

Blister Height from Side View

1713

172

170

169

168

161

166

---*IM

*

168

£170

---

1698

*18

Operator No.

Figure 29: Blister Height (in no. of pixels) measured by 2 operators

This overall standard deviation between the two operators was found to be 1.44 pixels which

translates into a repeatability coefficient of 4.3 pixels i.e. 75.68 pm. This was deemed acceptable

for the experiment.

5.2 Measurement Setup for Blister Flow

Blisters measured using the above setup were driven by an actuator in order to determine what the

flow profiles coming from them were like. This data was then used to correlate the measured

dimensions with the final flow rates.

The setup used for this purpose was a test system used by Daktari Diagnostics for testing the

working of their cartridges. This setup consisted of the actuators as well as the locating

mechanism for the cartridges. A Sensirion SLG1430-480 flow sensor was used to measure the

liquid flow rates from the blister.

5.3 Validation of Blister Numerical Model

In order to validate the model, the dimensions of a set of 4 blisters were measured using the

optical setup described in Section 5.1. Only the blister height and base radius were measured

from the side and top views of the blister. These dimensions were used as input for the blister

model, and the flow rates at specific crush depths was noted. These flow rates were then

compared with those obtained from experiment. Figure 30 summarizes the results.

. .

M

.

..

........................................

24

22

14

-

12

3.5

3.7

3.9

4.1

4.3

4.5

4.9

4.7

5.1

5.3

Crush Depth (mm)

3A - Actual Flow

3B - Actual Flow

3C- Actual Flow

-2B

- Actual Flow

3A - Simulated Flow

3B3 - Simulated Flow

"" 3C - Simulated Flow

""" 2B - Simulated Flow

Figure 30: Plot of Experimental and Predicted Flow Rates from 5 Blisters

.

The fit between the model and the experimental values is not satisfactory. There are several

possible reasons for this:

1. Uncertainty in known dimensions

The uncertainty in the known dimensions i.e. radius and height are high enough that it is

possible that wrong input was being provided to the model.

2. Lack of information about other relevant dimensions of the system

Data regarding the other inputs to the model was not available. In particular, the lateral

misalignment and starting height of the actuator were not completely known. In the

absence of this data the expected values for these dimensions were used in the blister

model. However, flow rate variation caused by these dimensions has not been modeled.

3.

Observed Lateral Misalignment

Significant lateral misalignment was observed in the test setup at the time of flow

measurement. However, in the absence of actual data this information could not be used.

4.

Crumpling in the blister

Some crumpling of the blister did occur during these trials, and this could have led to

some of the differences between the model and reality.

It is important that these effects are considered and the blister validation process repeated in order

to verify the claims that follow.

6. Monte Carlo Analysis and Regression Models

Despite the lack of a successful validation experiment (see Chapter 5), it was decided to use the

model in a statistical simulation to determine what the behavior of the entire population of blister

packs was likely to be (when manufacturing began and provided the model was correct). The

method used is commonly known as the Monte Carlo technique. It involves the creation of a

pseudo-population of blisters and actuators and then actually plunging these virtual actuators into

the virtual blisters to produce virtual flow! A distribution of the flow parameters was built by

running thousands of virtual experiments.

6.1 Manufacturing Variation Data

The pseudo-population of blisters and actuators is built using data that informs us about their

statistical distribution and parameters. Table 2 shows the manufacturing variation data for the

various dimensions (see Section 4.2.1).

Table 4: Variation Data for the Blister and Actuator Dimensions

Standard Deviation

Mean Value

Distribution

Dimension

Base Radius

Normal

7.99 mm

80 pLm

Spherical Radius

Normal

6.2 mm

80 tm

Blister Height

Normal

6.16 mm

35 tm

Actuator Radius

Normal

7.27 mm

33 pm

Lateral Misalignment

Normal

0 mm

142 jim

Angular Misalignment

Normal

0 degrees

0.5 degree

Height of the Actuator

Uniform

13.43 mm

486 pm

This variation data has been obtained from a variety of sources. The base radius, spherical radius

and blister height are obtained from a combination of manufacturer data and the validation data

from Chapter 5. The actuator radius data was selected based on a standard deviation that would

provide 99.7% of produced parts conforming to the DIN 2768-1 specification. The lateral

misalignment, angular misalignment and height of the actuator are obtained from the analysis of

the instrument by Linares Error! Reference source not found.

6.2 Monte Carlo Algorithm

Following the generation of pseudo-population data, the algorithm consisted of using the blister

numerical model developed in Chapter 4 for plunging the blisters and determining the flow rates

from each setup. The algorithm is summarized below in Figure 31.

START

Generate a random blister

and actuator using the

population parameters for

each

Input NUMBER OF

TRIALS, N

Use the blister numerical

model to calculate

AVERAGE, MAXIMUM

AND MINIMUM FLOW

RATES

Input Blister and

Actuator Population

Parameters

Set Counter = I

No

Yes

Counter <= N?

Store the average,

maximum and minimum

flow rates in suitable

vectors

Counter = Counter + I

Display a histogram of the

stored flow rate data

Determine appropriate statistics

from the above simulations

STOP

Figure 31: Flowchart of the Monte Carlo Algorithm

Several different experiments were run using the above Monte Carlo simulation and their results

are summarized in Chapter 7.

7. Results and Discussion

Using the Monte Carlo algorithm described in the previous chapter, a simulation of 10,000

blisters was conducted to study the effect of variation on the flow rate. Based on the requirements

set forth by Daktari, the tolerance on the flow rate was set at +/- 20% of the mean flow rate. Any

blister-actuator configurations that caused a flow rate outside this range were deemed 'out-ofspecification'. For example, for a nominal flow rate of 10ptL/min, the flow would be considered

within spec if it were between 8piL/min and 12 pL/min.

7.1 Flow Rate Variation after considering only Blister Dimensional

Variation

To begin with, the robustness of the blister design with respect to an ideal actuator was studied.

This involved allowing the 3 blister dimensions, namely, base radius, spherical radius and blister

height to be randomly picked from suitable normal populations (see Table 4) while the actuator

dimensions remained constant at their mean values. Figure 32 shows the distribution of flow rates

for this situation. The three distributions capture the important elements of the overall flow rate

profile shown in Figure 10.

Table 5: Summary of Output Distribution Properties considering the variation in blister

dimensions alone

Average Flow Rate

Maximum Flow Rate

Minimum Flow Rate

Mean

20.0041

20.0896

19.9166

Standard Deviation

0.2293

0.2404

0.2369

Skewness

0.0333

0.4955

-0.4477

Coefficient of Kurtosis

2.9592

3.3527

3.2543

Lilliefor's Test for

> 0.5

< 0.001

< 0.001

Normality (p-value)

400

Frequency Dsrbution of Average FlowRat

300

100

r

Figure 32: Distribution of Flow Rates considering only Blister Variation