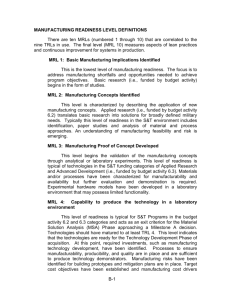

GAO BEST PRACTICES DOD Can Achieve Better Outcomes by

advertisement