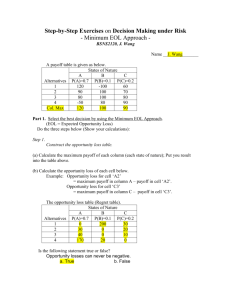

THE USE OF A PRODUCT END OF...

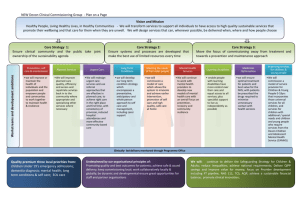

advertisement