Supportless PdFe nanorods as highly active electrocatalyst Wenzhen Li , Pradeep Haldar

advertisement

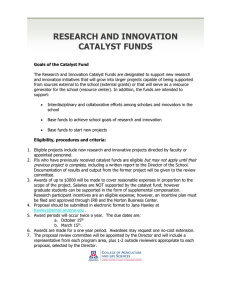

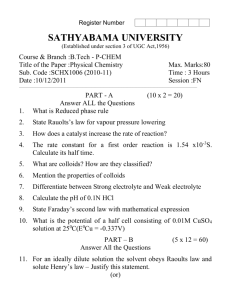

Electrochemistry Communications 11 (2009) 1195–1198 Contents lists available at ScienceDirect Electrochemistry Communications journal homepage: www.elsevier.com/locate/elecom Supportless PdFe nanorods as highly active electrocatalyst for proton exchange membrane fuel cell Wenzhen Li a,*, Pradeep Haldar b a b Department of Chemical Engineering, Michigan Technological University, Houghton, MI 49931, USA College of Nanoscale Science and Engineering (CNSE), State University of New York (SUNY) at Albany, NY 12206, USA a r t i c l e i n f o Article history: Received 11 March 2009 Received in revised form 29 March 2009 Accepted 31 March 2009 Available online 9 April 2009 Keywords: Nanorod Oxygen reduction Catalyst Palladium Fuel cells a b s t r a c t The PdFe nanorods (PdFe-NRs) with tunable length were synthesized by an organic phase reaction of [Pd(acac)2] and thermal decomposition of [Fe(CO)5] in a mixture of oleyamine and octadecene at 160 °C. They show a better proton exchange membrane fuel cell (PEMFC) performance than commercial Pt/C in working voltage region of 0.80–0.65 V, due to their high intrinsic activity to oxygen reduction reaction (ORR), reduced cell inner resistance, and improved mass transport. Ó 2009 Elsevier B.V. All rights reserved. 1. Introduction Highly active and low cost electrocatalysts are of great importance for large-scale commercial applications of PEMFCs [1,2]. One-dimensional (1-D) carbon nanotubes (CNTs) supported electrocatalysts have shown improved activity towards oxygen reduction reaction (ORR), durability and mass transport [3–6], however, still suffer the carbon corrosion issue [7]. Supportless 1-D metallic and multi-metallic electrocatalysts have recently attracted enormous attention [8–10], since they can offer unique benefits, such as (1) anisotropic morphology and (2) thin and dense metal catalyst layer, which lead to higher mass transport of reactants, (3) high aspect ratio, which is immune to surface energy driven coalescence via crystal migration. Pt and PtPd nanotubes with a diameter of 50 nm and length of 5–20 lm were reported to have improved ORR specific activities [9]. However, their relatively small electrochemical surface areas (ECSA) (<15 m2/g), due to its large wall thickness of 4–7 nm and inaccessible inner tube surface area, greatly limit the mass activity enhancement. In order to meet the fuel cell cost requirements, the research on decreasing Pt content in electrodes and replacing Pt by other inexpensive metals, such as Pd, Fe, Co, etc. were extensively studied [11–15]. Pd is considered less expensive than Pt (the price of Pd is 1/4–1/5 as that of Pt), but less active for the ORR. In an acid electrolyte the ORR exchange current density of Pd is 10 10 A/cm2, which is one magni* Corresponding author. Tel.: +1 906 487 2298. E-mail address: wzli@mtu.edu (W. Li). 1388-2481/$ - see front matter Ó 2009 Elsevier B.V. All rights reserved. doi:10.1016/j.elecom.2009.03.046 tude lower than that of Pt (10 9 A/cm2) [16]. Carbon supported Pd–M alloy nanoparticles [12,13], such as PdFe, PdCo and PdCoAu, have been demonstrated a comparable ORR activity as Pt. In this paper, we present a convenient synthesis method for preparing PdFe nanorods with a large ECSA of ca. 60 m2/g, and they show high performance in both three-electrode-cell and PEM single cell tests. 2. Experimental The synthesis procedures of PdFe-NR are described as follows: a mixture of 153 mg Pd(acac)2 (0.5 mmol) and 20 mL oleylamine (OAm) under a blanket of nitrogen was quickly heated to 110 °C and held for 30 min. After 120 lL Fe(CO)5 was injected into the synthesis system, the temperature was raised to 160 °C and held for 30 min. The solution was then cooled down to room temperature by removing the mantle heater. A mixture of 10 mL hexane and 50 mL ethanol was added and the product was separated by centrifugation (6000 rpm for 10 min). The product was cleaned by redispersing in a mixture of 10 mL hexane and 15 mL ethanol and separating by centrifugation for three times. The final PdFeNR product was dispersed in 10 mL hexane. 20 ml mixtures of OAm and octadecene (ODE) with volumetric ratio of 1:1 and 3:1 were used for synthesis of PdFe-NR(b) and PdFe nanoparticles (PdFe-NP), respectively. Pd nanoparticles (Pd-NP) with a diameter of 2–3 nm were synthesized by reduction of Pd(acac)2 in the presence of OAm and oleic acid at 200 °C for 30 min. These Pd-based NR and NP powders were obtained by filtrating their hexane solutions 1196 W. Li, P. Haldar / Electrochemistry Communications 11 (2009) 1195–1198 through a Nylon filter (pore size: 0.2 lm) and being dried at 60 °C in a N2-saturated oven. The composition, morphology and structure of these Pd-based nanocatalysts were analyzed by transmission elec- 180 Pd (111) P e 140 120 Pd (220) Pd (200) 160 Intensity / a.u. tron microscopy (TEM, JOEL2010, 200 kV), X-ray diffraction (XRD, SCINTAG-XDS2000, Cu Ka radiation, k = 1.5418 Å) and Induced couple plasma–atomic emission spectroscopy (ICP–AES). 100 80 Pd-NP 2.9 nm PdF NR PdFe-NR 2.7 nm 60 40 20 0 30 35 40 45 50 55 60 2 theta degree / 65 70 75 80 o Fig. 1. TEM images of PdFe-NP (a) and NR with a length of 10 nm (b), 50 nm (c), and 50 nm in one bundle (d), and XRD patterns of Pd-NP and PdFe-NR (e). 1197 W. Li, P. Haldar / Electrochemistry Communications 11 (2009) 1195–1198 distance corresponding to the highest ORR activity is around 0.273 nm for PdFe/C catalyst [13]. In our work, the Pd–Pd bond distance of the PdFe-NR is very close to this optimum Pd–Pd bond distance (0.273 nm). Theoretically, the chemical surface area (CSA) of a metal nanorod is inversely proportional to its diameter, but is independent with its length. The Pd-NR with a diameter of 3 nm has a CSA of 110 m2/g. The ECSA of PdFe-NR obtained from CV test (based on the hydrogen desorption peaks) is 60 m2/g, which gives a Pd utilization of 55%. The ORR activity for PdFe-NR and Pt/C catalysts measured using RDE technique in the three-electrode-cell is shown in Fig. 2. At 0.9 V (RHE), the PdFe-NR exhibits a lower ORR activity than Pt/C, however, as the voltage is low to 0.85 V, the mass activity (MA) for PdFe-NR is 284 mA/mgPd, which is slightly higher than 265 mA/mgPt for Pt/C, this trend is even larger when the voltage is decreased to 0.8 V: 1290 mA/mgPd for PdFe-NR vs. 805 mA/mgPt for Pt/C. The ORR curve of PdFe-NR is steeper than that of Pt/C, this is attributed to thin layer of PdFe-NR (no carbon, dense and thinner catalyst on GC electrode), which can facilitate oxygen transport to PdFe-NR surface. A 5-cm2-MEA with the PdFe-NR as cathode catalyst (0.22 mgPt/ 2 cm ) was fabricated by a self-developed screen-printing technique. The PdFe-NR based cathode catalyst layer is only around 1 lm. The H2–air PEMFC performance comparison of this MEA and the commercial MEA with Pt/C cathode catalyst of 0.5 mgPt/cm2 is shown in Fig. 3. At a high working voltage of 0.9 V, the mass activity of Pt/ C is 36 mA/mgPt, which is two times higher than PdFe-NR (18 mA/ mgPd). However, as the working voltage moves to the practical operation region (0.8–0.65 V), the cell performance of PdFe-NR is a PdFe-NR Pt/C 2 -2 0.1 M HClO4, 99.999% O2 o 10 mV/s, 65 C, 1600 rpm, anodic scan 2 2 25 µgPd/cm and 20 µgPt/cm -3 -4 -5 -6 -7 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 b 300 -1 E / V [RHE] 250 0.85 V 0.5 MA SA PdFe-NR Pt/C 0.4 200 0.3 150 0.2 100 0.9 V 0.1 0 0.0 -2 50 Specific Activity / mA.cm TEM images of PdFe NP and NR are shown in Fig. 1a–d. Using an OAm and ODE ratio of 1/3, uniformly dispersed PdFe nanoparticles with an average particle size of 2–4 nm are observed (Fig. 1a). With the ratio of OAm to ODE increasing to 1:1, PdFe-NR(b) with a diameter of 3 nm and short length of 10 nm were synthesized (Fig. 1b). When pure OAm was used for the synthesis, 50 nm-length PdFeNRs with a similar diameter of 3 nm were produced (Fig. 1c). Therefore, we demonstrated an easy approach to control the length of PdFe-NR by altering the volumetric ratio of OAm to ODE. It has been reported that the length of 1-D PtFe nanowire can be controlled by altering the surfactants ratio [17]. In our experiment, it is interesting to find that around 20–40 PdFe nanorods were selfassembled to ‘flower’-like bundles (Fig. 1d), and the distance between two nanorods is around 2–4 nm. This bundle structure is likely to form a thin and dense catalyst layer in a MEA, which can facilitate the mass transport of reactants. The composition of the PdFe-NR was controlled by injecting different amount of Fe(CO)5. For example, 0.12 mL gave a Pd–Fe ratio of 52:48 (determined by ICP–AES). XRD patterns of PdFe-NR and Pd-NP are shown in Fig. 1e. Broad Pd diffraction peaks are observed for both samples. The particle size based on calculation of Pd (2 2 0) diffraction peak by Debye–Sherrer formula is 2.7 nm for PdFe-NR and 2.9 nm for Pd-NP. This confirms the PdFe-NR has a small diameter. It is also observed that all Pd diffraction peaks of PdFe-NR shift to right, compared to Pd-NP. The Pd–Pd bond (inter-atomic) distance is 0.2729 nm for PdFe-NR, which is smaller than the bond distance of Pd-NP (0.2747 nm). It was reported the optimum Pd–Pd bond Mass Activity / mA.mg 3. Results and discussion 0 -1 i [mA/cm ] A conventional three-electrode-cell setup (electrolyte cell AFCELL3, Pine) with a glassy carbon working electrode, a reversible hydrogen reference electrode (HydroflexÒ) and a Pt wire counter electrode, was used for cyclic voltammetry (CV) and rotating disk electrode (RDE) tests of the PdFe-NR and Pt/C (20 wt%, BASF-FuelCell) samples at 65 °C. The working electrode was prepared by dropping 10 lL of the ink on the glassy carbon electrode. The ink was prepared by ultrasonically mixing 3 mg of PdFe-NR in 5 mL ethanol. 10 lL of 0.05 wt% Nafion was added on top to fix the electrocatalyst. For the Pt/C, 20 lL of the ink with 1 mg Pt/C/ml ethanol was dropped on the surface of glassy carbon and covered by 10 lL of 0.05 wt% Nafion. The CV test was conducted at 50 mV/s from 0.05 V to 1.0 V (vs. RHE). The ORR polarization curve was obtained at 10 mV/s from 0.35 V to 0.95 V (vs. RHE), using a rotating speed of 1600 rpm under oxygen (99.999%) bubbling. The working electrolyte is 0.5 M H2SO4 and 0.1 M HClO4 for CV and ORR tests, respectively. The MEA fabrication is based on a self-developed screen-printing technique. Briefly, the screen printing paste was prepared by adding PdFe-NR, solubilized Nafion, cyclohexanol and ethylene glycol to a small vial, and then was coated directly onto K+-form Nafion membrane (50 lm, DuPont, NRE212) to make cathode catalyst coated membrane (CCM). The thickness of PdFe-NR catalyst layer was determined by a digital micrometer, five points of the CCM was randomly measured and the average thickness was reported. Pt/C was screen-printed on the other side of the CCM as anode catalyst. After the K+-form CCM was converted to H+-form, it was assembled into a 5-cm2-PEMFC-hardware. A commercial MEA (BASF-FuelCell) with 0.5 mgPt/cm2 for both anode and cathode was also tested as a controlled sample. The cell temperature was kept at 65 °C and the relative humidity (RH) of both anode and cathode are 100%. After the MEA was activated at 0.7 V for 8 h, its PEMFC performance was tested by applying a constant voltage and collecting the corresponding current density and in situ inner resistance (based on current interruption technique). Fig. 2. (a) Polarization curves of the ORR on PdFe-NR and Pt/C (BASF-FuelCell), and (b) mass activity and specific activity of PdFe-NR and Pt/C in three-electrode-celltest. 1198 W. Li, P. Haldar / Electrochemistry Communications 11 (2009) 1195–1198 shows a performance drop when the operation voltage is lower than 0.65 V, this could be attributed to ‘water flooding’ inside the catalyst layer. Future work focused on optimizing the catalyst layer compositions and the gas diffusion layer structures will be expected to improve its performance in high current density region, and this is currently under study in my group. 0.9 2 PdFe-NR, 0.22mgPd/cm 0.8 0.7 2 Pt/C, 0.50mgPt/cm E/ V 0.6 0.5 4. Conclusions 0.4 0.3 2 Anode catalyst: Pt/C (40wt%, BASF-FuelCell), 0.5 mgPt/cm o Cell: 65 C, 100% RH Anode/cathode: H2/air, 0.1/0.4 slpm, 0/0 psi 0.2 0.1 0.0 0 100 200 300 400 500 600 700 800 2 i [mA/cm ] Fig. 3. Polarization curves of single PEMFCs (5-cm2-MEA) with PdFe-NR and Pt/C (BASF-FuelCell) cathode catalysts. In this study, uniform PdFe-NR with a diameter of 3 nm and controllable length of 10–50 nm were synthesized through a single-step organic phase reduction process. The ratio of two surfactants (OAm and ODE) was found to effectively control the length of nanorods in range of 10–50 nm. The PdFe-NR demonstrates a better PEMFC performance than commercial Pt/C in practical working voltage region (0.80–0.65 V), which can be attributed to their high intrinsic activity towards ORR, reduced cell inner resistance, and improved mass transport. Acknowledgements higher than that of Pt/C e.g. at 0.75 V, the current density and the mass power density of PdFe-NR is 1.65 times higher than Pt/C (245 mA/cm2 vs. 148 mA/cm2, 184 mW/cm2 vs. 111 mW/cm2), even on half precious metal loading (0.50 mgPt vs. 0.22 mgPd). When the working voltage is in the range of 0.8–0.65 V, the polarization curve is a combined effect of catalyst activity, inner cell resistance and mass transport. Therefore, the I–V curves show the PdFe-NR catalyst has a better overall PEMFC performance in this working voltage region. We attributed the improved PEMFC performance to: (1) the advantageous Pd–Pd bond distance (0.2729 nm) for PdFe-NR, which favors oxygen double bond dissociation [13], thus improves the ORR intrinsic activity; (2) the unique 1-D nanorod structure and the super thin catalyst layer (1 lm vs. 25 lm for Pt/C catalyst layer), which can reduce the overall internal resistance of PdFe-NRbased MEA (6 mX vs. 9 mX for Pt/C-based MEA) and improve the mass transport. It was reported that a 60–80% mass activity (power density) benefit could be gained if the ohm resistance and mass transport were effectively reduced [2]. Here we clearly demonstrated this benefit through using super-thin 1-D PdFe-NR-based catalyst layer. The reported supportless nanocatalyst synthesis and MEA fabrication strategies have a great potential to be extended to other highly active bi-, tri-metallic 1-D electrocatalysts, such as PdCo/Ni-NR for ORR and PtRuCo-NR for methanol oxidation reaction. It should be noted that the PdFe-NR-based MEA We thank Seth Knupp, Dr. Thomas Murray and Dr. Wentao Wang for their helps with XRD and TEM analysis and MEA fabrication. References [1] W. Vielstich, A. Lamm, H.A. Gaisteiger, Handbook of Fuel Cells – Fundamentals, Technology and Applications, vol. 2, Wiley, NY, 2003. [2] H.A. Gaisteiger, S.S. Kocha, B. Sompalli, F.K. Wagner, Appl. Catal. B 56 (2005) 9. [3] G.L. Che, B.B. Lakshmi, E.R. Fisher, C.R. Martin, Nature 393 (1998) 346. [4] W.Z. Li, C.H. Liang, W.J. Zhou, J.S. Qiu, Z.H. Zhou, G.Q. Sun, Q. Xin, J. Phys. Chem. B 107 (2003) 6292. [5] G. Girishkumar, K. Vinodgopal, P.V. Kamat, J. Phys. Chem. B 108 (2004) 19960. [6] W.Z. Li, X. Wang, Z.W. Chen, M. Waje, Y.S. Yan, Langmuir 21 (2005) 9386. [7] X. Wang, W.Z. Li, M. Waje, Y.S. Yan, J. Power Sources 158 (2006) 154. [8] M. Debe, A.K. Schmoechel, G.D. Vernstrom, P. Atanasoki, J. Power Sources 161 (2006) 1002. [9] Z.W. Chen, M. Waje, W.Z. Li, Y.S. Yan, Angew. Chem. Int. Ed. 46 (2007) 4060. [10] H. Wang, C. Xu, F. Cheng, S. Jiang, Electrochem. Commun. 9 (2007) 1212. [11] O. Savadogo, K. Lee, K. Oishi, S. Mitsushima, N. Kamiya, K.I. Ota, Electrochem. Commun. 6 (2004) 105. [12] J.L. Fernandez, V. Raghuveer, A. Mathiram, A.J. Bard, J. Am. Chem. Soc. 127 (2005) 13100. [13] M-H. Shao, K. Sasaki, R.R. Adzic, J. Am. Chem. Soc. 128 (2006) 3526. [14] N.A. Vante, H. Tributsch, Nature 323 (1986) 431. [15] R. Bashyam, P. Zelenay, Nature 443 (2006) 63. [16] R.P. O’Hayre, S.-W. Cha, W. Colella, F.B. Prinz, Fuel Cell Fundamentals, Wiley, NY, 2006. [17] C. Wang, Y. Hou, J. Kim, S. Sun, Angew. Chem. Int. Ed. 46 (2007) 63.