KMU-307 Chemıcal Reactıon Engıneerıng

advertisement

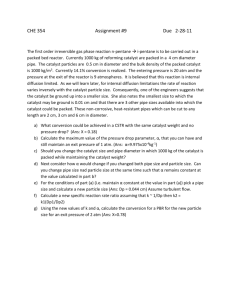

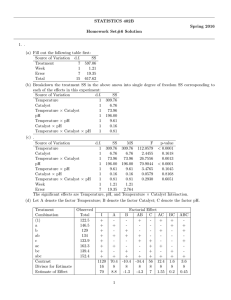

Hacettepe University Chemical Engineering Department KMU-307 Chemical Reaction Engineering Res. Asst. Gökçe Dicle Kalaycıoğlu KMU-307 CHEMICAL REACTION ENGINEERING TERM PROJECT Ethyl acetate is an extensively used solvent and can be formed by the vaporphase etherification of acetic acid and ethanol. The reaction was studied using a microporous resin as a catalyst in a packed bed reactor [Ind. Eng. Chem. Res., 26(2), 198 (1987)]. The reaction is first order in ethanol and pseudo zero order in acetic acid. For an equal molar feed rate of acetic acid and ethanol, the specific reaction rate is 1.2 dm3/g cat / min. The total volumetric feed rate is 25 dm3/min, the initial pressure is 10 atm, the temperature is 118°C, and the pressure drop parameter, , is 0.01 g-1. a. Calculate the maximum weight of catalyst that one could use and maintain an exit pressure above 1 atm. (Ans.: W = 99g) b. Plot X, y, and as a function of distance down the packed bed reactor. c. Determine the catalyst weight necessary to achieve 90% conversion. (Ans.: W = 57 g) d. What is the ratio of catalyst needed to achieve the last 5% (85 to 90%) conversion to the weight necessary to achieve the first 5% conversion (0 to 5%) in the reactor? e. How would your answer to part (b) change if both the particle diameter and pipe diameter were increased by 50% when 1. the flow is laminar 2. the flow is turbulent f. Write a few sentences describing and explaining what would happen if the pressure drop parameter a is varied. g. What generalizations can you make about what you learned in this problem that would apply to other problems?