Document 10462574

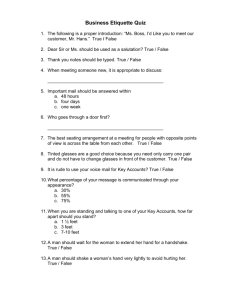

advertisement