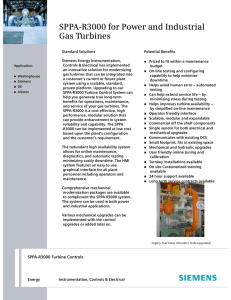

Micro-TB Controller

For Industrial Gas Turbines up to 15 MW

Answers for Energy

Siemens Energy is a world leader in industrial gas turbines for power generation

and mechanical drive applications. As part of the comprehensive portfolio of customer services activities, Siemens can offer modern control system upgrades for

our TB fleet of gas turbines.

Maintaining Customer Operations

Siemens Micro-TB Controller is a modern micro processor

based control system designed specifically to retrofit

existing TB gas turbine controllers.

By replacing the existing control system with a modern

equivalent from Siemens, not only will this transform

reliability and availability, but it will open the door to a

range of other benefits that have become the expected

standard on modern turbine installations. The Micro-TB

Series provides a particularly cost-effective Controls

upgrade.

Based on a modern compact PLC and a TFT touch screen,

it offers a standard configuration of pre-engineered

modules which will suit almost any TB Generator or

Pump installation and, subject to review, compressor

sets. The screen display provides the operator with userfriendly mimics and messages which portray the

operational status of the turbine. In addition, any

abnormal conditions will be displayed in concise time

tagged alarm or trip messages. This provides the site

operators with a first-line diagnostic tool to reduce any

unscheduled down time. Installation is straightforward,

as the Micro-TB is particularly compact, and may be wall

mounted or erected on stanchions.

Although the design is standardised, a range of preengineered options allow for considerable flexibility in

meeting the specific needs of individual customers.

Customer Benefits

Improved reliability - resulting in fewer trips and

lower spares costs.

Improved availability - due to better diagnostics,

easier repair, and dependable spares supply.

Easier starting - as this is now fully automated, and

traditional flame viewing is replaced by an ‘inference’

system.

Improved operator interface - providing

comprehensive information on the major systems and

reducing operational errors.

Enhanced diagnostics - from clear and

comprehensive on-screen status displays.

Improved accuracy & stability - allowing maximum

use of the operational envelope.

Enhanced communications ability - using widely

accepted networking protocols.

Options

Various options are available to further enhance the

package including:

Fuel throttle valve & actuator replacements

Fuel shut-off valve and slam-shut valve replacements

Vibration monitoring systems

Instrumentation upgrades

Connections to external communication systems

through an electronic data network.

www.siemens.com/energy

Published by and copyright © 2013:

Siemens AG

Energy Sector

Freyeslebenstrasse 1

91058 Erlangen, Germany

Siemens Energy, Inc.

4400 Alafaya Trail

Orlando, FL 32826-2399, USA

For more information, please contact

our Customer Support Center.

Phone: +49 180 524 70 00

Fax:

+49 180 524 24 71

(Charges depending on provider)

E-mail:support.energy@siemens.com

www.siemens.com/energy

Energy Service Division

LCN 2013 - F33.20 LN

Printed on elementary chlorine-free

bleached paper.

All rights reserved. Trademarks mentioned in

this document are the property of Siemens AG,

its affiliates, or their respective owners.

Subject to change without prior notice.

The information in this document contains

general descriptions of the technical options

available, which may not apply in all cases.

The required technical options should

therefore be specified in the contract.