Jose A. Briones, Ph.D. SpyroTek Performance Solutions, LLC

advertisement

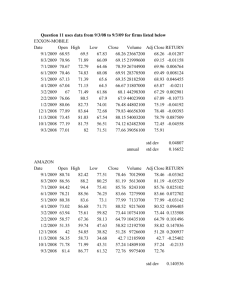

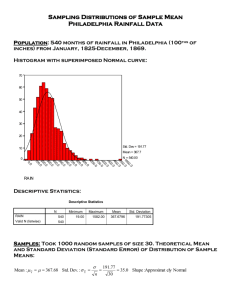

Jose A. Briones, Ph.D. SpyroTek Performance Solutions, LLC Palisade’s Risk Analysis Conference, October 2009 Introduction Model description Financial modeling inputs Scenario modeling Results analysis Profitability projections in a manufacturing environment are directly tied to how the sales forecast fits with the capability of the operation. When a company has a large portfolio of products with very different operational production rates, the manufacturing capacity of the plant will be significantly impacted by the product mix to be produced. This in turn will have a radical effect on the output of the plant and the allocation of the fixed cost of production. There is a need to integrate the financial model with the production forecast and production capabilities In this case we present an example where a company is trying to meet the following objectives Balance sales and production of certain families of products to maximize profit Maintain a diverse product line Properly price each individual product based on the impact to the manufacturing schedule and fixed cost allocation Model uses @Risk probabilistic decision analysis software Monte Carlo simulation Risk and opportunity analysis Designed for complex projects with high levels of uncertainty Inputs contain high number of variables, either technical or financial with a high degree of uncertainty, assumptions and dependencies ▪ ▪ ▪ ▪ New product development assessment Capital spending decisions Value chain analysis Production and sales forecasting analysis Eliminates use of “one at a time” cases Analyzes thousands of cases simultaneously Generates a range of outcomes Outcome charts are analyzed to make decisions on direction Input values are entered in range format – Width and shape of range are critical inputs Definition of the input ranges is the most critical step Do not start with the typical value, start with the range, define the shape of the function (10%, 50%, 90% probability). There are multiple choices for the shape of the input range: Triangular: Most common for initial assumptions Normal distribution: Used when more accurate input data is available PERT: When data is in form of probabilities Gamma distribution: Good to model pricing distributions in B-B cases Multiline product portfolio 4 Product families – A, B, C, D A, C and D are existing products B is a new product family that is meant to replace product A ▪ B has higher margins than A but lower production rates ▪ C and D have higher margins than B but even lower production rates 4 Production lines – 1, 2, 3, 4 Products A and B can be made in all production lines ▪ Products A and B have different production rates Products C and D can only be made in lines 3 and 4 ▪ Products C and D have different production rates Post-treatment facility after production lines limits total production rate Product Family A Line 1 125 Kg/hr/line Product Family B Line 2 87.5 Kg/hr/line Product Family C Post-Treatment Facility Line 3 62.5 Kg/hr/line Product Family D 37.5 Kg/hr/line Line 4 350 Kg/hr Manufacturing facility was being upgraded and debottlenecked. Production rates for all products were expected to change as the project progresses throughout the year. Variable margins are different for all product families and cannot be known with absolute certainty Sales forecast is not exact, has variability Fixed costs billed in foreign exchange Business manager wants to forecast total business profitability and profit by product under 2 scenarios: 1. Maintain forecast for Product C and D fixed and evaluate if Product A should be discontinued and replaced by better performing Product B 2. Maximize sales of Product C, maintain D forecast fixed, again evaluate Product B vs. A Typical Production Target of product C, Kg/mo Production Target of product D, Kg/mo Production Rate of Product A, lines 1 and 2, Kg/hr Production Rate of Product B, lines 1 and 2, Kg/hr Rate of Production product C, lines 3 and 4 Kg/hr Rate of Production product D, lines 3 and 4 Kg/hr Maximum Production Rate 4 lines running, Kg/hr Var Margin Product A US$/kg Var Margin Product B US$/kg Var Margin Product C US$/kg Var Margin Product D US$/kg Plant fixed cost Euros/month Selling & Admin costs Euros/month Projected fixed cost savings Euros/month US Dollar/ Euro Exchange Rate 15,000 10,000 Range Min 10,000 5,000 Range Max 20,000 15,000 250 175 125 75 350 240 165 90 60 330 260 200 140 80 370 $2.50 $2.75 $4.00 $5.00 $2.30 $2.60 $3.50 $4.50 $2.70 $3.00 $4.50 $5.50 500,000 € 50,000 € 75,000 € 0.8 450,000 € 550,000 € 45,000 € 55,000 € 65,000 € 90,000 € 0.7 0.95 Plant will be run at full capacity to maximize profit. Production capacity of products A or B is dependent on the free time left after meeting production targets for C and D. Common method of dividing total fixed cost by the total production is not acceptable when products have widely different production rates. In order to calculate profitability by product, we need to allocate fixed costs based on projected run time for each product family This allows us to make the right decisions as to which product to promote or stop promoting. Do not subsidize slow running products. Calculate % manufacturing time used to meet forecast of C & D Calculate % manufacturing time available to manufacture A or B Calculate maximum production of A or B subject to treatment line constraints Estimate total profitability and gross profit by product Run sensitivity analysis 0.772 0.829 % of treatment line time devoted to A + B Grades / Column 5.0% 100.0% 60 Minimum Maximum Mean Std Dev Values 50 40 D % of treatment line time devoted to Product D / Column 30 20 C Minimum Maximum Mean Std Dev Values A or B 10 0.0854 0.1304 0.1031 0.00761 1000 9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 0.0 0.7431 0.8577 0.8027 0.0176 1000 20% of Production time is allocated to C & D Values 1000 0. % of treatment line time devoted to A or B, C & D % of treatment line time devoted to Product C / Column Minimum Maximum Mean Std Dev 0.0549 0.1432 0.0941 0.0155 Total theoretical capacity, Product A plus Products C & D, kg/yr 2.699 5.0% 92.3% 7 2.906 90.0% 7.7% Values x 10^-6 6 5.0% 0.0% Total theoretical capacity, Product A plus Products C & D, kg/yr Minimum Maximum Mean Std Dev Values A 5 B 4 3 2633085.3298 3018607.7688 2803346.2034 63912.9226 1000 Total theoretical capacity, Product B plus products C & D, kg/yr 2 1 3.1 3.0 2.9 2.8 2.7 2.6 2.5 2.4 2.3 0 Minimum Maximum Mean Std Dev Values 2357095.8177 2788160.2845 2604929.4916 65567.7702 1000 Values in Millions Substituting Product A with Product B Results in Lower Total Plant Capacity Profitability, Product A vs. Product B US$/yr 0.000 17.3% 11.3% 8 75.9% 75.8% 6.8% 12.9% Profitability, Product A Case US$/yr / Column A 7 Values x 10^-7 7 1.450 6 A 5 Minimum Maximum Mean Std Dev Values B -1219775.4188 2289688.1319 596061.7364 598929.0090 1000 4 Profitability, Product B Case US$/yr / Column 3 2 1 2.5 2.0 1.5 1.0 0.5 0.0 -0.5 -1.0 -1.5 0 Minimum Maximum Mean Std Dev Values Values in Millions Product B has a lower probability of losses than product A -1091259.4015 2484366.8328 752663.4930 597144.6785 1000 Fixed cost US$/kg Products A, B, C, D 5.45 5.0% 99.8% 2.5 2.0 7.40 90.0% 0.2% Fixed cost US$/kg Product D 5.0% 0.0% Minimum Maximum Mean Std Dev Values B Fixed cost US$/kg Product C 1.5 A 1.0 C Minimum Maximum Mean Std Dev Values D 0.5 Values in $ Slower production rates result in much higher fixed costs for Products C and D 9 8 7 6 5 4 3 2 0.0 1 $4.9476 $8.3905 $6.3397 $0.6112 1000 $2.8058 $5.5362 $3.8559 $0.4473 1000 Fixed cost US$/kg Product A Minimum Maximum Mean Std Dev Values $1.8656 $2.9132 $2.3665 $0.1899 1000 Fixed cost US$/kg Product B Minimum Maximum Mean Std Dev Values $2.0664 $3.1881 $2.5700 $0.1997 1000 Gross Profit Products A, B, C, D US$/Kg -0.22 0.48 5.0% 2.9% 2.5 Profit Product A US$/Kg / Column 5.0% 12.1% Minimum Maximum Mean Std Dev Values 2.0 A 1.5 Profit Product B US$/Kg / Column B 1.0 D Minimum Maximum Mean Std Dev Values C 0.5 2 1 Values in $ Profit Product D US$/Kg / Minimum Maximum Mean Std Dev -$0.4348 $0.8052 $0.2133 $0.2216 1000 Profit Product C US$/Kg / 0 -1 -2 -3 -4 -5 0.0 Product D has a Negative Gross Profit Due to Long Production Cycles -$0.5836 $0.7011 $0.1335 $0.2097 1000 -$4.5032 -$0.7534 -$2.3397 $0.6452 Minimum Maximum Mean Std Dev Values -$1.5576 $1.4447 $0.1441 $0.4867 1000 % of treatment line time devoted to A/B, C & D Grades 0.448 5.0% 100.0% 60 0.575 90.0% 0.0% % of treatment line time devoted to A + B Grades / Column 5.0% 0.0% Minimum Maximum Mean Std Dev Values D 50 40 0.3699 0.6080 0.5203 0.0384 5000 % of treatment line time devoted to Product D / Column 30 20 C Minimum Maximum Mean Std Dev Values A or B 10 ~50% of time devoted to C & D 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0.0 0 0.0849 0.1304 0.1032 0.00770 5000 % of treatment line time devoted to Product C / Column Minimum Maximum Mean Std Dev Values 0.2963 0.5094 0.3766 0.0374 5000 Total theoretical capacity, Product A vs. B plus Products C & D, kg/yr 2.700 5.0% 100.0% 7 2.906 90.0% 0.0% Total theoretical capacity, Product A plus Products C & D, kg/yr A 6 Values x 10^-6 5.0% 0.0% Minimum Maximum Mean Std Dev Values 5 4 2596788.1735 3001093.4875 2803246.3861 62557.3764 5000 B 3 Total theoretical capacity, Product B plus products C & D, kg/yr 2 1 3.2 3.0 2.8 2.6 2.4 2.2 2.0 1.8 0 Minimum Maximum Mean Std Dev Values 1942146.1959 2697819.5994 2362657.7945 120704.1615 5000 Values in Millions Production of B v.s A results in a more significant loss of capacity compared to Scenario 1 Profitability, Product A vs B Case US$/yr 0.00 1.45 1.2% 51.1% 47.7% 13.2% 72.0% 14.8% Profitability, Product A Case 7 US$/yr / Column 6 V a lu e s x 1 0 ^ -7 B A 5 Minimum -852160.3638 Maximum 3287264.9694 Mean 1405082.2802 Std Dev 608985.6034 Values 4 3 5000 Profitability, Product B Case US$/yr / Column 2 1 0 Minimum -2021651.9911 Maximum 3250368.3280 Mean 735213.2672 Std Dev 665321.2558 5000 4 3 2 1 0 -1 -2 -3 Values Values in Millions Production of A has less than 2% probability of losses, 48% probability of profit >1.5 MM $ Fixed cost US$/kg Products A, B, C & D 5.40 5.0% 99.8% 2.0 1.8 7.43 90.0% 0.2% Fixed cost US$/kg Product D / Column 5.0% 0.0% Minimum Maximum Mean Std Dev Values A 1.6 B 1.4 $4.6730 $8.7315 $6.3410 $0.6228 5000 Fixed cost US$/kg Product C / Column 1.2 1.0 C 0.8 D Minimum Maximum Mean Std Dev Values 0.6 0.4 0.2 Values in $ Fixed cost US$/kg Product A / Column 9 8 7 6 5 4 3 2 1 0.0 $2.6522 $5.8660 $3.8579 $0.4645 5000 Minimum Maximum Mean Std Dev Values Fixed Cost of Product A drops in this scenario $1.2306 $2.6219 $1.9559 $0.2068 5000 Fixed cost US$/kg Product B. / Column Minimum Maximum Mean Std Dev Values $1.8782 $3.2967 $2.5241 $0.2136 5000 Profit Products A, B C & D US$/Kg 0.00 0.91 0.7% 94.3% 5.0% 13.2% 86.7% 0.1% B 1.4 -$0.1944 Minimum -$4.8411 Maximum $1.2512 Maximum -$0.3715 Mean $0.5441 Mean -$2.3410 $0.2233 Std Dev Minimum 1.8 1.6 Profit Product D US$/Kg / Column Profit Product A US$/Kg / Column A Std Dev Values 5000 1.2 Profit Product B US$/Kg / Column 1.0 0.8 D 0.6 C Minimum -$0.6366 Maximum $1.0344 Mean $0.2593 0.4 Std Dev $0.2276 0.2 Values Profit Product C US$/Kg / Column 2 1 0 -1 -2 -3 -4 -5 0.0 Values in $ Minimum -$2.0249 Maximum $1.5637 Mean $0.1421 Std Dev $0.5091 Values Profit of Product A increases in this scenario 5000 5000 Values $0.6569 5000 Scenario 1 - A Scenario 1 - B Scenario 2 - A Scenario 2 - B % time devoted to C & D 20% 20% 48% 48% Production of C 0.2 MM kg/yr 0.2 MM kg/yr 0.7 MM kg/yr 0.7 MM kg/yr Total Plant Capacity 2.8 MM kg/yr 2.6 MM kg/yr 2.8 MM kg/yr 2.4 MM kg/yr Profitability 0.6 MM$/yr 0.75 MM$/yr 1.4 MM $/yr 0.7 MM $/yr 17% 11% 1% 13% Probability of Losses Scenario 2 with sales of Product A has the best probability for higher profits Scenario 1 – Fixed Cost/Kg Scenario 1 – Gross Profit/Kg Scenario 2 – Fixed Cost/Kg Scenario 2 – Gross Profit/Kg Product A $2.37 $0.13 $1.96 $0.54 Product B $2.57 $0.21 $2.52 $0.26 Product C $3.86 $0.14 $3.85 $0.14 Product D $6.34 -$2.34 $6.34 -$2.34 Fixed cost for Product A drops in Scenario 2, gross profit increases Product D has negative gross profit under both scenarios Profitability, Product A Case US$/yr / Column Regression Coefficients US Dollar/ Euro Exchange Rate 0.73 -0.51 Plant fixed cost Euros/month 0.34 Var Margin Product A US$/kg 0.22 Maximum Production Rate 4 lines running, kg/hr 0.13 Projected fixed cost savings Euros/month 0.10 Operational Efficiency Days of the week operating 0.07 Production of product C, Kg/mo 0.06 0.06 Var Margin Product C US$/kg -0.05 Selling & Admin costs Euros/month 0.05 Rate of Production product D, Kg/mo 0.04 Var Margin Product D US$/kg Production Rate of Product A, lines 1 and 2, kg/hr 0.03 Hours/day operating 0.02 Coefficient Value 0.8 0.6 0.4 0.0 -0.2 -0.4 -0.6 0.2 0.01 Production of product D, Kg/mo Maximum Production Rate for the 4 lines is a critical factor for profitability of A Product D was discontinued Emphasis was placed on Product C sales Product B sales were not emphasized but sold based on market demands Product A had been overpriced relative to fixed costs. Findings allowed pricing flexibility and an increase in market share Jose A. Briones, Ph.D. SpyroTek Performance Solutions, Irving, TX Brioneja@Spyrotek.com (469) 737-0421 Theoretical capacity Products A & B Kg/mo 154.4 5.0% 100.0% 8 172.8 90.0% 0.0% 5.0% 0.0% Theoretical capacity Product A Kg/mo / Column Minimum Maximum Mean Std Dev Values 6 5 143825.4377 182165.7345 163603.8872 5589.9594 5000 4 Theoretical capacity Product B kg/mo / Column 3 2 1 Values in Thousands 190 180 170 160 150 140 130 120 110 100 90 0 80 Values x 10^-5 7 Minimum Maximum Mean Std Dev Values 89846.9886 157539.8296 126888.1712 10465.5035 5000 Lines 3 and 4 fully devoted to Products C and D Production of product C & D, Kg/mo Comparison with Triang(55000,60000,65000) 56.6 63.4 5.0% 5.0% 0.0010 0.0009 0.0008 0.0007 0.0006 0.0005 0.0004 0.0003 0.0002 0.0001 0.0000 Production of product C, Kg/mo / Column 5.0% 5.0% Minimum Maximum Mean Std Dev Values 55075.1959 64901.1442 59999.9773 2041.4514 5000 Triang(55000,60000,65000) 70 60 50 40 30 20 10 0 Minimum Maximum Mean Std Dev Values in Thousands Production of C goes from 15 M to 60 M Kg/mo 55000.0000 65000.0000 60000.0000 2041.2415 Production of product D, Kg/mo / Column Minimum Maximum Mean Std Dev Values 9008.7846 10992.7913 10000.0010 408.2882 5000