Control Charts for Attributes

advertisement

C. J. Spanos

Control Charts for Attributes

The p (fraction non-conforming),

c (number of defects) and the

u (non-conformities per unit) charts.

The rest of the magnificent seven.

L8

1

C. J. Spanos

Yield Control

100

100

80

80

60

60

40

40

20

20

0

0

10

20

30

0

0

10

20

30

Months of Production

L8

2

C. J. Spanos

The fraction non-conforming

The most inexpensive statistic is the yield of the production

line.

Yield is related to the ratio of defective vs. non-defective,

conforming vs. non-conforming or functional vs. nonfunctional.

We often measure:

• Fraction non-conforming (p)

• Number of defects on product (c)

• Average number of non-conformities per unit area (u)

L8

3

C. J. Spanos

The p-Chart

The p chart is based on the binomial distribution:

n-x

n x

x = 0,1,...,n

p (1-p)

x

mean np

variance np(1-p)

the sample fraction p= D

n

mean p

variance p(1-p)

n

P{D = X} =

L8

4

C. J. Spanos

The p-chart (cont.)

p must be estimated. Limits are set at +/- 3 sigma.

m

mean p

variance p(1-p)

nm

Σ pi

p=

i=1

m

(in

(in this

this and

and the

the following

following discussion,

discussion, "n"

the number

number of

of

"n" isis the

samples

in

each

group

and

is

the

number

"m"

samples in each group and "m" is the number of

of groups

groups

that

thatwe

weuse

usein

in order

orderto

todetermine

determinethe

the control

controllimits)

limits)

L8

5

C. J. Spanos

Designing the p-Chart

In general, the control limits of a chart are:

UCL= µ + k σ

LCL= µ - k σ

where k is typically set to 3.

These formulas give us the limits for the p-Chart (using the

binomial distribution of the variable):

p can be estimated:

p(1-p)

n

p(1-p)

LCL = p - 3

n

UCL = p + 3

pi =

Di

i = 1,...,m (m = 20 ~25)

n

m

Σ pi

p=

L8

i=1

m

6

C. J. Spanos

Example: Defectives (1.0 minus yield) Chart

0.5

UCL 0.411

0.4

0.3

0.232

0.2

0.1

LCL 0.053

0.0

0

10

20

30

Count

"Out of control points" must be explained and eliminated

before we recalculate the control limits. This means that

setting the control limits is an iterative process! Special

patterns must also be explained.

L8

7

C. J. Spanos

Example (cont.)

After the original problems have been corrected, the

limits must be evaluated again.

L8

8

C. J. Spanos

Operating Characteristic of p-Chart

In order to calculate type I and II errors of the p chart we

need a convenient statistic.

Normal approximation to the binomial (DeMoivre-Laplace).

if n large and np(1-p) >> 1, then

P{D = x} =

n

p x (1-p) (n-x) ~

x

(x-np) 2

1

e 2np(1-p)

2πnp(1-p)

In other words, the fraction nonconforming can be treated as

having a nice normal distribution! (with µ and σ as given).

This can be used to set frequency, sample size and control

limits. Also to calculate the OC.

L8

9

C. J. Spanos

Binomial distribution and the Normal

bin 10, 0.1

bin 100, 0.5

bin 5000 0.007

4.0

3.0

2.0

65

50

60

45

55

40

50

45

1.0

40

35

0.0

L8

35

30

25

20

15

Quantiles

Quantiles

Quantiles

Moments

Moments

Moments

10

C. J. Spanos

Designing the p-Chart

Assuming that the discrete distribution of x can be

approximated by a continuous normal distribution as

shown, then we must:

• choose n so that we get at least one defective with

0.95 probability.

• choose n so that a given shift is detected with 0.50

probability.

or

• choose n so that we get a positive LCL.

Then, the operating characteristic can be drawn from:

β = P { D < n UCL /p } - P { D < n LCL /p }

L8

11

C. J. Spanos

The Operating Characteristic Curve (cont.)

The OCC can be calculated two distributions are

equivalent and np=λ).

p = 0.20,

LCL=0.0303,

UCL=0.3697

L8

12

C. J. Spanos

In reality, p changes over time

L8

(data from the Berkeley Competitive Semiconductor Manufacturing Study)

13

C. J. Spanos

The c-Chart

Sometimes we want to actually count the number of defects.

This gives us more information about the process.

The basic assumption is that defects "arrive" according to a

Poisson model:

-c x

x = 0,1,2,..

p(x) = e c

x!

µ = c, σ2 = c

This assumes that defects are independent and that they

arrive uniformly over time and space. Under these

assumptions:

UCL = c + 3 c

center at c

LCL = c - 3 c

and c can be estimated from measurements.

L8

14

C. J. Spanos

Poisson and the Normal

poisson 2

poisson 20

poisson 100

130

10

30

120

8

110

6

100

20

4

90

80

2

10

70

0

Quantiles

Quantiles

Quantiles

Moments

Moments

Moments

L8

15

C. J. Spanos

Example: "Filter" wafers used in yield model

Fraction Nonconforming (P-chart)

0.5

UCL 0.454

Fraction Nonconforming

0.4

¯ 0.306

0.3

0.2

LCL 0.157

0.1

0

2

4

6

8

10

12

14

Defect Count (C-chart)

Number of Defects

200

UCL 99.90

100

Ý 74.08

LCL 48.26

0

0

2

4

6

8

10

12

14

Wafer No

L8

16

C. J. Spanos

Counting particles

Scanning a “blanket” monitor wafer.

Detects position and approximate size of particle.

y

x

L8

17

C. J. Spanos

Scanning a product wafer

L8

18

C. J. Spanos

Typical Spatial Distributions

L8

19

C. J. Spanos

The Problem with Wafer Maps

Wafer maps contain information that is very difficult to

enumerate

A simple particle

happening.

L8

count

cannot

convey

what

is

20

C. J. Spanos

Special Wafer Scan Statistics for SPC applications

•Particle Count

•Particle Count by Size (histogram)

•Particle Density

•Particle Density variation by sub area (clustering)

•Cluster Count

•Cluster Classification

•Background Count

Whatever

Whatever we

we use

use (and

(and we

we might

might have

have to

to use

use more

more

than

one),

must

follow

a

known,

usable

distribution.

than one), must follow a known, usable distribution.

L8

21

C. J. Spanos

In Situ Particle Monitoring Technology

Laser light scattering system for detecting particles in

exhaust flow. Sensor placed down stream from

valves to prevent corrosion.

Laser

chamber

to pump

Detector

Assumed to measure the particle concentration in

vacuum

L8

22

C. J. Spanos

Progression of scatter plots over time

The endpoint detector failed during the ninth lot, and was

detected during the tenth lot.

L8

23

C. J. Spanos

Time series of ISPM counts vs. Wafer Scans

L8

24

C. J. Spanos

The u-Chart

We could condense the information and avoid outliers by

using the “average” defect density u = Σc/n. It can be

shown that u obeys a Poisson "type" distribution with:

µu = u, σ2u = u

n

so

UCL =u + 3 u

n

u

LCL =u - 3 n

where u is the estimated value of the unknownn of u.

The sample size n may vary. This can easily be

accommodated.

L8

25

C. J. Spanos

The Averaging Effect of the u-chart

poisson 2

average 5

5.0

10

4.0

8

6

4

2

0

L8

3.0

2.0

1.0

0.0

Quantiles

Quantiles

Moments

Moments

26

C. J. Spanos

Filter wafer data for yield models (CMOS-1):

0.5

Fraction Nonconforming (P-chart)

UCL 0.454

Fraction Nonconforming

0.4

¯ 0.306

0.3

0.2

LCL 0.157

0.1

0

2

4

6

8

10

12

14

200

Number of Defects

Defect Count (C-chart)

UCL 99.90

100

Ý 74.08

LCL 48.26

0

0

2

4

6

8

10

12

14

6

Defect Density (U-chart)

Defects per Unit

5

4

UCL 3.76

3

× 2.79

2

LCL 1.82

1

0

2

4

L8

6

8

10

12

14

27

Wafer No

C. J. Spanos

The Use of the Control Chart

The control chart is in general a part of the feedback loop

for process improvement and control.

Input

Process

Output

Measurement System

L8

Verify and

follow up

Detect

assignable

cause

Implement

corrective

action

Identify root

cause of problem

28

C. J. Spanos

Choosing a control chart...

...depends very much on the analysis that we are

pursuing. In general, the control chart is only a small

part of a procedure that involves a number of statistical

and engineering tools, such as:

• experimental design

• trial and error

• pareto diagrams

• influence diagrams

• charting of critical parameters

L8

29

C. J. Spanos

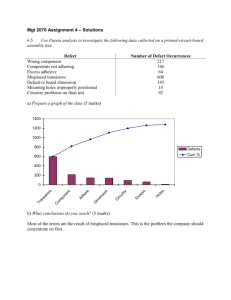

The Pareto Diagram in Defect Analysis

Typically, a small number of defect types is responsible

for the largest part of yield loss.

The most cost effective way to improve the yield is to

identify these defect types.

figure 3.1 pp 21 Kume

L8

30

C. J. Spanos

Pareto Diagrams (cont)

Diagrams by Phenomena

• defect types (pinholes, scratches, shorts,...)

• defect location (boat, lot and wafer maps...)

• test pattern (continuity etc.)

Diagrams by Causes

• operator (shift, group,...)

• machine (equipment, tools,...)

• raw material (wafer vendor, chemicals,...)

• processing method (conditions, recipes,...)

L8

31

C. J. Spanos

Example: Pareto Analysis of DCMOS Process

DCMOS Defect Classification

100

80

Percentage

60

occurence

cummulative

40

20

others

se particles

rn bridging

sed contacts

ontamination

scratches

s problems

vious layer

0

Though the defect classification by type is fairly easy, the

classification by cause is not...

L8

32

C. J. Spanos

Cause and Effect Diagrams

(Also known as Ishikawa,fish bone or influencediagrams.)

figure 4.1 pp 27 Kume

Creating such a diagram requires good understanding of

the process.

L8

33

C. J. Spanos

An Actual Example

L8

34

C. J. Spanos

Example: DCMOS Cause and Effect Diagram

Past Steps

Parametric Control

Particulate Control

rec. handling

inspection

SPC

automation

calibration

cassettes

SPC

equipment

monitoring

cleaning

Defect

skill

vendor

experience

shift

Operator

chemicals

loading

transport vendor

boxes

Handling

Wafers

utilities

filters

Contamination Control

L8

35

C. J. Spanos

Example: Pareto Analysis of DCMOS (cont)

DCMOS Defect Causes

100

80

percentage

60

occurence

cummulative

40

20

others

smiff boxes

inspection

loading

utilities

equipmnet

0

Once classification by cause has been completed,

we can choose the first target for improvement.

L8

36

C. J. Spanos

Defect Control

In general, statistical tools like control charts must be

combined with the rest of the "magnificent seven":

• Histograms

• Check Sheet

• Pareto Chart

• Cause and effect diagrams

• Defect Concentration Diagram

• Scatter Diagram

• Control Chart

L8

37

C. J. Spanos

Logic Defect Density is also on the decline

Y = [ (1-e-AD)/AD ]2

L8

38

C. J. Spanos

What Drives Yield Learning Speed?

L8

39