Ass4Ans

advertisement

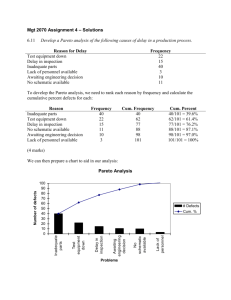

Mgt 2070 Assignment 4 – Solutions 6.5 Use Pareto analysis to investigate the following data collected on a printed-circuit-board assembly line. Defect Wrong component Components not adhering Excess adhesive Misplaced transistors Defective board dimension Mounting holes improperly positioned Circuitry problems on final test Number of Defect Occurrences 217 146 64 600 143 14 92 a) Prepare a graph of the data (5 marks) 1400 1200 1000 800 Defects Cum % 600 400 200 H ol es ss Ex ce y ui tr C irc io n en s D im Ad he re po ne nt C om Tr an s is t or s 0 b) What conclusions do you reach? (5 marks) Most of the errors are the result of misplaced transistors. This is the problem the company should concentrate on first. S6.3 The overall average of a process you are attempting to monitor is 50 units. The average range is 4 units. The sample size you are using is n = 5. a) What are the upper and lower control limits of the appropriate mean charts? (5 marks) b) What are the upper and lower control limits of the appropriate range chart? From table S6.1 where n = 5, we have A2 = 0.577, D4 = 2.115, and D3 = 0. UCL X X A 2 R 50 0.577 4 52.308 LCL X X A 2 R 50 0.577 4 47.692 UCL R D 4 R 2.115 4 8.456 LCL R D3 R 0 4 0 S6.7 Pet Products Inc. caters to the growing market for cat supplies, with a full line of products ranging from litter to toys to flea powder. One of its newer products, a tube of fluid that prevents hairballs in long-haired cats, is produced by an automated machine set to fill each tube with 63.5 grams of paste. To keep this filling process under control, four tubes are pulled randomly from the assembly line every 4 hours. After several days, the data shown in the table that follows resulted. Set control limits for this process and graph the sample data for both the x- and R-charts. Is the process in control? x R x R 1 63.5 2.0 14 63.3 1.5 2 63.6 1.0 15 63.4 1.7 3 63.7 1.7 4 63.9 0.9 16 63.4 1.4 17 63.5 1.1 Sample Number 5 6 7 8 63.4 63.0 63.2 63.3 1.2 1.6 1.8 1.3 Sample Number 18 19 20 63.6 63.8 63.5 1.8 1.3 1.6 9 63.7 1.6 21 63.9 1.0 10 63.5 1.3 22 63.2 1.8 11 63.3 1.8 23 63.3 1.7 12 63.2 1.0 24 64.0 2.0 13 63.6 1.8 25 63.4 1.5 X 63.49, R 1.5, n 4. From table S6.1 where n = 4, we have A2 = 0.729, D4 = 2.282, and D3 = 0. UCL X X A 2 R 63.49 0.729 1.5 64.58 LCL X X A 2 R 63.49 0.729 1.5 62.40 UCL R D 4 R 2.282 1.5 3.423 LCL R D3 R 0 1.5 0 (4 marks) Adjustable weight in grams X-bar Control Chart (2 marks) 65 64.5 64 63.5 63 62.5 62 61.5 61 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Sample Average range in grams R Control Chart (2 marks) 4 3.5 3 2.5 2 1.5 1 0.5 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Sample The x-bar and range charts both show that the process is in control. (2 marks) S6.19 The smallest defect in a computer chip will render the entire chip worthless. Therefore, tight quality control measures must be established to monitor these chips. In the past, the percentage defective at a California-based company has been 1.1%. The sample size is 1,000. Determine upper and lower control chart limits for these computer chips. Use z = 3. In a sample size of 1,000, the mean fraction defective in the sample (p-hat) is 0.011 (ie 1.1%). UCL pˆ p z pˆ p z p(1 - p) 0.011(0.989) 0.011 3 0.0209 n 1000 p(1 - p) 0.011(0.989) LCL pˆ p z pˆ p z 0.011 3 0.0011 n 1000 (10 marks)