Slide and Swing System PowerPoint Training

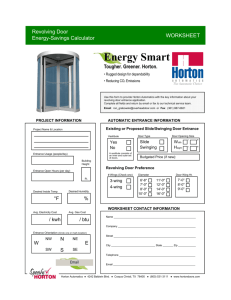

advertisement

Slide and Swing Products The Horton Advantage Copyright © 2007 by Horton Automatics Horton Automatics From its very inception in 1960, with the introduction of the world’s First Automatic Sliding Door for Commercial Use , Horton Automatics continued to develop many industry “Firsts” INDUSTRY FIRSTS First to gain nationwide building code acceptance for the automatic sliding door. First internal shockproof checking in sliding door operator design (patented). First U.L. listing of the swing/slide breakaway feature on an exit (patented). First to market the automatic pass-through window. First automatic door manufacturer to catalogue a motion detector with safety beam. First U.S. manufacturer to develop the automatic Folding door and receive U.L. listings on the operator, folding door system and breakaway mechanism. Horton Automatics has since developed the Industry’s broadest product line and the Industry’s best lead times. A Division of Overhead Door Corporation Copyright © 2007 by Horton Automatics A Sanwa Shutter Company Horton Automatics Network of Independent Distributors Worldwide positioning √ Corpus Christi - North and South America & Far East √ Telford - Europe and Africa Corpus Christi, TX Copyright © 2007 by Horton Automatics Telford, England Slide and Swing Products Sliding Doors Drive Mechanisms Door Types Design Options Door Construction Horton Solid Breakout Extrusion Horton Corner Block vs. Mass Produced Thru Bolt Folding Doors Door Types Design Options Swing Doors Operator types Mounting and Design Options Copyright © 2007 by Horton Automatics Automatic Sliding Doors Industry’s broadest product offering (4) Header sizes, (3) Operator/Drive systems, Sizes: 4”x 6”, 6”x 8”, 6”x 6”, 8”x 6” Electric linear drive, Electric belt drive, Pneumatic Perimeter/Jamb mounted, Surface mount, Ability to customize for special applications and conditions Horton specializes in custom jobs Most durable door panel construction Horton-exclusive corner block All slide door packages include choice of premium sensors Dual photo beams Provides sensing redundancy for added threshold safety Copyright © 2007 by Horton Automatics Automatic Sliding Doors Drive Mechanism Linear Drive – Profiler® Series 2000 Horton-Exclusive Slim 4” x 6” Header allows flush assembly to 4” jambs Ease of installation - quick header to jamb fastening Threadless 1/2” dia. tempered stainless steel rod 1/8 HP motor Single slide to 9’-0” wide; bi-part to 16’-0” wide Up to 200 lbs per panel (non-breakout) Includes ProfilerStorm® Series hurricane rated doors DURABLE COUPLER EFFICIENT DIRECT COUPLED MOTOR Copyright © 2007 by Horton Automatics STAINLESS STEEL ROD ROBUST CLUTCH MECHANISM Automatic Sliding Doors Drive Mechanism Belt Drive – ProSlide® Series 2003 Ideal for Commercial Applications 6” x 6” header 3/4” steel reinforced nylon drive belt 1/8 HP motor Single slide door up to 9’-0” wide, bi-part up to 16’-0” Exceeds common specs for automatic slide doors Up to 250 lbs per panel (non-breakout) Copyright © 2007 by Horton Automatics Automatic Sliding Doors Drive Mechanism Belt Drive – ProSlide® Series 2003T Telescoping Ideal for commercial and hospital applications Maximizes door opening 8” x 6” header 3/4” steel reinforced nylon drive belt 1/8 HP motor Singles up to 12’-0” wide, biparts up to 16’-0” Single slide door up to 90lbs per panel Copyright © 2007 by Horton Automatics Automatic Sliding Doors Drive Mechanism Belt Drive – Series 2001 HD-Slide® Ideal for Heavy Duty Commercial/Industrial Applications 6” x 8” header Heavy duty 1/8 HP motor, 1/4 HP also available 1” steel reinforced nylon drive belt Single slide door up to 9’-0” wide, bi-part up to 16’-0” Up to 500 lbs per panel for non-breakout single slide Up to 300 lbs per panel for non-breakout bipart Includes Elegant® Series 2500 all-glass doors Copyright © 2007 by Horton Automatics Automatic Sliding Doors Drive Mechanism Pneumatic – Series 1000 Ideal for Pharmaceutical, Clean Room and Industrial applications Requires clean air source to operate Can be made explosion proof by Mounting all electronics in non-hazardous area Using intrinsically safe module switching devices All pneumatic control and switching devices Copyright © 2007 by Horton Automatics Automatic Sliding Doors Door Types Type 010 Sliding panel ‘X’ slides along interior of fixed sidelite ‘O’. Type 110 Slide-swing panel ‘SX’ slides along exterior of fixed sidelite ‘O’. Type 310 Slide-swing panel ‘SX’ slides along interior of swing-out sidelite ‘SO’. Type 410 Slide-swing panel ‘SX’ slides between fixed sidelite ‘O’ and swing-out sidelite ‘SO’ Type 110 Surface Mount Slide-swing panel ‘SX’ slides along exterior of wall. Copyright © 2007 by Horton Automatics Automatic Sliding Doors Design Options Copyright © 2007 by Horton Automatics Automatic Sliding Doors Design Options Copyright © 2007 by Horton Automatics Automatic Sliding Doors Design Options Copyright © 2007 by Horton Automatics Automatic Sliding Doors Design Options Copyright © 2007 by Horton Automatics Automatic Sliding Doors Design Options Copyright © 2007 by Horton Automatics Automatic Sliding Doors Design Options Horton-Exclusive Flush Panic Device Push bar releases the breakout latch and remains flush with surface of the door. Dogging is not required. Can be used on inside (110) or outside (310) slider breakouts Fits all door panel sizes from 27” (9’ bipart) and up. Copyright © 2007 by Horton Automatics Competitive Comparison Door Panel Construction Horton-Exclusive SOLID break-out extrusion Horton Solid bar with continuous interlocking Typical Mass Produced Door ONLY 2 ¼” interlock at strike end Hollow extrusion Sloppy operation Stanley Shown Horton Advantages: • Robust design increased durability and support • Solid operation that you can “feel” • Continuous scissor action Copyright © 2007 by Horton Automatics Wheels mount to extrusion! Competitive Comparison Door Panel Construction Horton SOLID break-out bar with continuous interlocking Horton Continuous torsion bar Copyright © 2007 by Horton Automatics Typical Mass Produced Door Torsion bar only at the corner Anatomy of a more durable door Door Panel Construction Horton-Exclusive Corner Block Design Grade 8 ¼ - 20 Bolts Cut to length Corner Blocks add strength Copyright © 2007 by Horton Automatics Massive bottom rail web for superior strength (4) 10-24 X ¾” self threading FHMS secure corner block to horizontal rail Anatomy of a more durable door Door Panel Construction Horton-Exclusive Corner Block Design Four 10-24 bolts secure corner block to horizontal rail Two Grade 8, 1/4-20 bolts secure corner block to vertical rail Concave steel backup plate engineered as built-in self locking device for Grade 8 bolts Copyright © 2007 by Horton Automatics Competitive Comparison Horton Corner Block Panel Mass-Produced Thru Bolt Corner Block Vertical Wall Steel Back Up Plate Vertical Rail Horizontal Rail Concave steel back-up plate engineered as built-in self locking device for the Grade 8 Bolts Copyright © 2007 by Horton Automatics Muntin Thin steel ¼” Flimsy thru stamping hold bolts rods Bottom rail Competitive Comparison Mass-Produced Thru Bolt Tapping plate / block located inside vertical interlock rail Holes drilled in vertical rail for rod adjustment and filled with plastic plug Copyright © 2007 by Horton Automatics Competitive Comparison Thru Bolt Construction After Wear at Installation Rails Can Twist and Misalign Panel Becomes Damaged Copyright © 2007 by Horton Automatics Automatic Folding Doors FoldingAccess® Series 4-4200 Ideal for commercial and hospital applications Maximizes door opening in narrow corridors Heavy-duty Series 4000 operator 6” x 6” header Meets emergency egress requirements Copyright © 2007 by Horton Automatics Automatic Folding Doors Door Types Fold-in Types Folds to interior and breaks away to exterior Fold-out Types Folds and breaks away to exterior. Copyright © 2007 by Horton Automatics Automatic Folding Doors Design Options Electromagnetic Locks Hold panels in locked positions under normal conditions with 1000 lbs. min. force. Flush Panic Bar (Horton Exclusive) Depressed panic bar releases magnetic lock and allows panel to breakout 90° from any point of travel. Interior View Copyright © 2007 by Horton Automatics Swing Doors Fully Automatic - governed by ANSI 156.10 Typically Sensor Activated Require External Safety Devices Faster Opening Speeds Allowed Guide Rails Required Swing Side Low Energy - governed By ANSI 156.19 Typically “Knowing Act” Activated Less Costly than Full Automatic Slower Opening Speed No External Safety Devices Required Copyright © 2007 by Horton Automatics Automatic Swing Doors Operator Types HD-Swing® Series 4000 Heavy duty 1/8 HP motor Maximum-duty Quadracoil™ spring closing (4 independent coil springs separated by teflon discs and enclosed in spring box) 6”x 6” side access header or 4 ½” x 6” bottom access header EasyAccess® Series 7000 1/15 HP motor designed for low-energy ADA handicap applications Spring closing 6”x 6” or 4”x 6” side access headers Both available in surface mount or Overhead Concealed configurations Copyright © 2007 by Horton Automatics Automatic Swing Doors Mounting Types – Surface Mount All arm configurations available for both Series 4000 and 7000. Surface mount operators available in singles or pairs. Copyright © 2007 by Horton Automatics Automatic Swing Doors Mounting Types – Overhead Concealed Complete door package available for both Series 4000 and 7000. Overhead Concealed operators available in singles or pairs. Copyright © 2007 by Horton Automatics Automatic Swing Doors Overhead Concealed Power Arm Options Direct Drive The operator output shaft connects to a concealed power arm in the top web of the door. The power arm serves as the door top pivot. Copyright © 2007 by Horton Automatics Automatic Swing Doors Overhead Concealed Power Arm Options Independent Pivot The operator output shaft connects to an arm that transmits power to the door via a slide block connected to the arm. The power arm works in a track that is mounted in the top web of the door. The door pivot is independent of the operator Allows for operator maintenance without removing the door panel. Copyright © 2007 by Horton Automatics Automatic Swing Doors Operator Options HD-Swing® Series 4000LE Combines heavy duty features of Series 4000 with low energy functionality of Series 7000 Heavy duty 1/8 HP motor Maximum-duty Quadracoil™ spring closing Slower opening speed “Knowing Act” activation No external safety devices required 6”x 6” side access header or 4 ½”x 6” bottom access header Surface mounted or overhead concealed Singles or pairs Designed for Low Energy ADA Applications of Large and/or High Traffic doors. Copyright © 2007 by Horton Automatics Automatic Swing Doors Operator Options Fire Door Surface Mount Operators Series 7900, 4900 or 4900LE Operator equipped with U.L. approved "Fire Exit Hardware" type GXHX as found in the U.L. Building Materials Directory. Required U.L. equipment supplied by others includes door, frame, hinges, automatic fire detectors or central alarm control Rated equipment must comply with NFPA 101 & NFPA 80 Fire Door Requirements. Fire exit hardware latches the door closed to contain the fire or smoke and prevent it from spreading to other areas of the 6”x 6” or 4”x 6” side access header Singles or pairs Copyright © 2007 by Horton Automatics Automatic Swing Doors Operator Options Fire Door Package Series 4900DP or 4900DP-LE with Overhead Concealed Operators INDUSTRY FIRST - Complete fire rated system that includes door, exit device and concealed heavy duty automatic operator. Heavy duty operator concealed within steel header. 18-gauge hollow metal door panel, honeycomb or steel stiffened core with up to 3 hour rating Low-profile push bar resists abuse and maximizes opening Heavy duty pinned continuous hinge Full power or low energy operation Singles, pairs or double-egress Designed for high traffic entrances that must meet building, fire, and safety codes. Copyright © 2007 by Horton Automatics Automatic Swing Doors Operator Options Pneumatic – Series 5100 Surface Mount Ideal for Pharmaceutical, Clean Room and Industrial applications Requires clean air source to operate Can be made explosion proof by Mounting all electronics in non-hazardous area Using intrinsically safe module switching devices All pneumatic control and switching devices Copyright © 2007 by Horton Automatics