Vaporization

advertisement

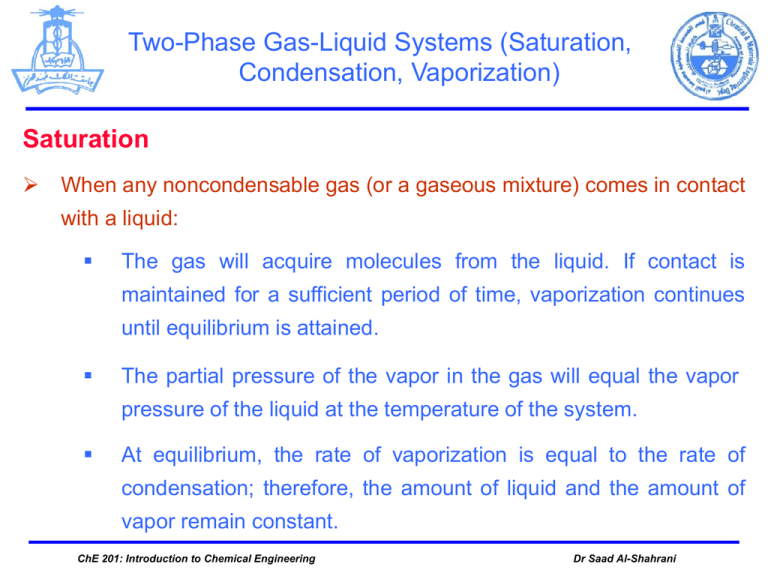

Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Saturation When any noncondensable gas (or a gaseous mixture) comes in contact with a liquid: The gas will acquire molecules from the liquid. If contact is maintained for a sufficient period of time, vaporization continues until equilibrium is attained. The partial pressure of the vapor in the gas will equal the vapor pressure of the liquid at the temperature of the system. At equilibrium, the rate of vaporization is equal to the rate of condensation; therefore, the amount of liquid and the amount of vapor remain constant. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) After equilibrium is reached no more net liquid will vaporize into the gas phase. The gas is then said to be saturated with the particular vapor at the given temperature. We also say that the gas mixture is at its dew point. The dew point for the mixture of pure vapor and noncondensable gas means the temperature at which the vapor just starts to condense. At the dew point the partial pressure of the vapor is the vapor pressure. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) When air is saturated with water, the ideal gas law can be applied to both air and water vapor with excellent precision. Thus, we can say that the following relations hold at saturation: * or Because V and Tare the same for the air and water vapor. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Example: suppose you have a saturated gas, say water in air at 51°C, and the pressure on the system is 750 mm Hg absolute. What is the partial pressure of the air? If the air is saturated, Solution The partial pressure of the water vapor is p* at 51°C. You can look in a handbook, or use the steam tables, and find that p* = 98 mm Hg. Then ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) yair pair 652 0.87 ptotal 750 ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Example: Oxalic acid H2C2O4 is burned at atmospheric pressure with 248% excess air, so that 65% of the carbon burns to CO2. Calculate the dew point of the product gas. Solution: Basis: 1 mol H2C2O4 Chemical reaction equations: H2C2O4 + 0.5O2 → 2 CO2 + H2O H2C2O4 → 2CO + H20 + 0.5O2 O2 required= 0.5 mol Mol O2 entering: (1 + 2.48)(0.5 mol O2) = 1.74 mol O2 ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Component Mol in Mol out With nco2= (0.65)(2) = 1.30, Component Mol nH2O nco2 nco 1.3 nc2 1.59 nN2 6.55 Total 11.4 ChE 201: Introduction to Chemical Engineering 1.0 0.7 Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) yH 2O = 1 mol H2O/11 .14 mol total = 0.0898 The partial pressure of the water in the product gas (at an assumed atmospheric pressure) determines the dew point of the stack gas: p*H2O = yH2O (pTotal) = 0.0898(101.3 kPa) = 9.09 kPa (1.319 psia) From steam tables, the dew point temperature: T=316.5 K ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Condensation Condensation is the change of vapor (in a noncondensable gas) to liquid. Some typical ways of condensing a vapor in a gas are: Cool it at constant system total pressure (the volume changes). Cool it at constant total system volume (the pressure changes). Compress it isothermally (the volume changes). ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Example: If a pound of saturated air at 75oF and 1 atm (the vapor pressure of water is 0.43 psia at 75oF) is compressed isothermally to 4 atm (58.8 psia), almost three-fourths of the original content of water vapor now will be in the form of liquid. and the air still has a dew point of 75°F. Remove the liquid water, expand the air isothermally back to 1 atm , and you will find that the dew point has been lowered to about 36°F. Here is how to make the calculations. Let 1 = state at 1 atm and 4 = state at 4 atm with z = 1.00 for both components. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Effect of an increase of pressure on saturated air, removal of condensed water, and a return to the initial pressure at constant temperature. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Pick as a basis 0.43 mol of H20. For saturated air at 75°F and 4 atm: I For the same air saturated at 75oF and 1 atm: Because the moles of air in state 1 and in state 4 are the same, the material balances simplify to That is, 24.5% of the original water will remain as vapor after compression. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) After the air-water vapor mixture is returned to a total pressure of 1 atm, to get the partial pressure of the water vapor the following two equations apply at 75°F: p H 2O ptotal n H 2O ntotal (0.245)(0.43) 0.00717 14.7 From these two relations you can find that pH2O = 0.105 psia pair = 14.6 ptotal = 14.7 psia The pressure of the water vapor represents a dew point of about 36°F. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Example: Emission of volatile organic compounds from processes is closely regulated. Both the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have established regulations and standards covering emissions and frequency of exposure. This problem concerns the first step of removal of benzene vapor from an exhaust stream using the process shown in Figure El7.2a. The process has been designed to recover 95% of the benzene from air by compression. What is the exit pressure from the compressor? ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) The vapor pressure of benzene at 26 oC p*=99.7 mm Hg ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Exiting components in the gas phase from the compressor: mol of benzene = 0.018 (0.05) = 0.90 X 10-3 g mol mol of air = 0.982 g mol total gas = 0.983 g mol y Benzene exiting =0.9 x 10-3/0.983 = 0.916 X 10-3 The partial pressure of the benzene is 99.7 mm Hg so that ptotal = 99.7 / 0.916 x 10-3 = 109 x 103 mm Hg ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Vaporization Vaporization is the reverse of condensation, namely the transformation of a liquid into vapor (in a noncondensable gas). You can vaporize a liquid into a noncondensable gas, and raise the partial pressure of the vapor in the gas until the saturation pressure (vapor pressure) is reached at equilibrium. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Evaporation of water at constant pressure and a temperature of 65°C. ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) Example: What is the minimum number of cubic meters of dry air at 20°C and 100 kPa that are necessary to evaporate 6.0 kg of liquid ethyl alcohol if the total pressure remains constant at 100 kPa and the temperature remains 20°C? Assume that the air is blown through the alcohol to evaporate it in such a way that the exit pressure of the air-alcohol mixture is at 100 kPa. Solution: Basis: 6.0 kg of alcohol 20 oC 100 kPa Air Alcohol 6.0 kg p*alcohol at 20°C = 5.93 kPa ChE 201: Introduction to Chemical Engineering 100 kPa saturated Air-alcohol mixture Mol. wt. ethyl alcohol = 46.07 Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) The minimum volume of air means that the resulting mixture is saturated; any condition less than saturated would require more air. p *Alcohol n Alcohol p Air n Air Once you calculate the number of moles of air, you can apply the ideal gas law. Since pAlcohol = 5.93 kPa pAir = ptotal - pAlcohol = (100 - 5.93)kPa = 94.07 kPa 6.0 kg alcohol 1 kg alcohol 94.07 kg mol air 2.07 kg mol air 46.07 kg alcohol 5.93 kg mol alcohol ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani Two-Phase Gas-Liquid Systems (Saturation, Condensation, Vaporization) V Air 2.07 kg mol air 8.314 (kPa)(m 3 ) 293(K) 50.4 m 3 at 20 o C and 100 kPa (kg mol)(K) 100 (kPa) ChE 201: Introduction to Chemical Engineering Dr Saad Al-Shahrani