Enterprise Computer Applications

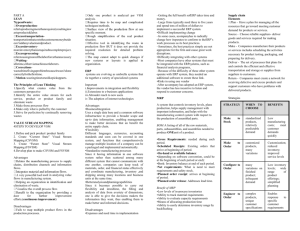

advertisement

Enterprise Computer Applications Peter Ping Liu, Ph D, PE, CQE, OCP and CSIT Professor and Coordinator of Graduate Programs School of Technology Eastern Illinois University Charleston, IL 61920 Enterprise application is based upon the actual process. A Typical Manufacturing Organization Is Engaged in: • Designing the System • Operating and Controlling the System Source: W. J. Stevenson, Production/Operations Management System Design • • • • • • Product and service design Process and strategy selection Capacity planning Facility planning Work system design Location planning Source: W. J. Stevenson, Production/Operations Management System Controlling • • • • • • • • • Forecasting Inventory/materials management Material requirement planning Just-in-time system Quality assurance Sourcing Scheduling Maintenance Project management Source: W. J. Stevenson, Production/Operations Management Customers Needs Are the Reasons for the Existence of the Organization. A Manufacturing Enterprise Needs People and Teamwork in the Organization to Meet the Needs of Customers. People and Process Need Support with Shared Knowledge and Systems. Any Manufacturing Organization Has Three Major Categories of Activities (Processes): Product/Process Definition, Manufacturing, and Customer Support. Every Organization Has to Manage Its Resources and Responsibilities Effectively. A Manufacturing Company Requires Support and Collaboration from Other Organizations. Put Them All Together to Form a World Class Manufacturer Enterprise Started with Islands of Applications Evolution of Manufacturing The Future of Enterprise Application Is Integration. Technical Issues • • • • • • • • • • Enterprise architecture Application server and middleware Component-based development Database servers Data warehousing Enterprise resource planning Enterprise networking Enterprise messaging and communication Internet commerce and collaboration Project and system management Source: Enterprise System Integration, J. M. Myerson (ed) Enterprise Resources Planning (ERP) Is Emerging. ERP Potential Functions: Financial • • • • • • • • • • Account receivable (AR) Account payable (AP) Asset accounting Cash financing Cost accounting Executive information system Financial consolidation General ledger Profitability analysis Standard costing ERP Potential Functions: Human Resources • • • • • • Time accounting Payroll Personnel planning Travel expenses Training Human resource development ERP Potential Functions: Operations and Logistics • • • • • • • • • Inventory management Materials requirement planning (MRP) Plant maintenance Production planning Project management Purchasing Quality management Shipping Vendor evaluation ERP Potential Functions: Sales and Marketing • • • • Order management Pricing Sales management Sales planning Major Players of ERP Vendor Origin Salient Features BAAN Holland An early ERP vendor Oracle United States A relative newcomer, but quickly gaining share PeopleSoft United States Originally focused on human resource management SAP Germany The pioneer and the largest firm JD Edwards United States Internet emphasis Source: T. H. Davenport, “Putting the Enterprise into the Enterprise System,” Harvard Business Review, July-August, 1998 An Example of Enterprise Resource Planning: Made2Manage For small and medium size companies as make-to-order make-to-stock engineer-to-order assemble-to-order mixed-mode manufacturers Made2Manage Enterprise Resource Planning Has Four Modules • Customer order management—Generate quotes, sales orders, custom-configure products, and more. • Materials management—Automate shop floor and inventory data collection and track material lots to seamlessly manage your material resources and inventory transactions. • Production management—Create job orders, capture costs and monitor production so you can build your products more profitably. • Financial management—Manage cash flow, key accounting tasks, budget forecasting, payroll, HR, and more. Made2Manage ERP Customer Order Management • Processing Sales Orders—Quickly enter sales orders into your system and jumpstart the fulfillment process. • Quoting and Estimating—Create reliable quotes by linking to bills of material, routings, the M2M Product Configurator, or the price summary worksheet. Made2Manage ERP Materials Management • Inventory Control—Identify and track information on each standard part so you can make the best possible inventory management decisions. • Tracking Material Lots—Automatically track raw materials, subassemblies and final assemblies to their origins. • Shop Floor Data Collection—Automate the entry and enhance the accuracy of your daily labor, inventory transactions, and shipping and receiving with wireless bar coding technologies. • Multi-Dimensional Inventory—Measure inventory in multiple dimensions and capture inventory transactions in alternative units of measure. • Physical Inventory—Collect, reconcile and post count quantities against on-hand inventory balances and generate general ledger transactions. Made2Manage ERP Production Management (1) • Job Orders—Quickly and easily create and track job orders, drive material requirements, and examine costs throughout the production process. • Order Costing—Accumulate and report costs as they flow through your system and post them to the general ledger. • Monitoring Production—View job order costs in real time and compare accumulated costs to projected job order costs. • Creating Routings—Track the path a part follows through production, including the work centers and operations needed to produce the part, create standard or non-standard routings, and monitor costs. • Bills of Material—Keep up-to-date information on the components and sub-contractors used to produce your product, better balance lead times, reduce inventories, and improve cash flow. Made2Manage ERP Production Management (2) • Shipping and Receiving—Manage all aspects of receiving materials, returning goods, shipping finished goods, and executing subcontract work. • Notifying Employees—Automatically send messages to customers, suppliers and employees when key events occur. • Managing Engineering Change—Audit critical documents and create multiple revisions for the item master, standard BOMs, and routings. • Quality Management—Streamline quality compliance efforts by automating your business's paper-intensive processes. Made2Manage ERP Financial Management (1) • Budgeting/Cash Flow—Develop budget forecasts based on different sources and plan ahead for your future cash needs. • Accounts Payable/Receivable—Pay your suppliers at just the right time and automate the billing process for better tracking and analysis of your revenue streams. • General Ledger—Link all monetary functions, such as receivables, payables, payroll, and order costing, for greater visibility and control over your financial activities. • Advanced Reports—Create advanced financial reports and drill down into source data for further analysis. Made2Manage ERP Financial Management (2) • Payroll—Integrate your M2M ERP accounting functions with third-party payroll providers such as ADP and Abra Suite Payroll. • Human Resources—Manage employee relations, government mandates, and everchanging benefit options with the integrated Abra Suite HR. • Progress Billing—Divide your bill into separate increments and still track the whole process to generate needed cash flow. Made2Manage ERP Financial Management (3) • Bank Reconciliation—Monitor all your checking account transactions and streamline your cash management operations. • Compusoft Drill Down Tools—Drill down into supporting financial data directly from the trial balance and generate financial reports to meet your specific requirements. • FRx Forecaster—Reduce the time you spend on collecting and sorting through spreadsheets and other information from different departments.