Flate-Carcam

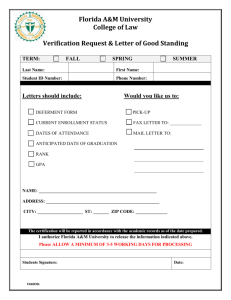

advertisement

Marilyn Barger, Ph.D., P.E. Beverly Hilderbrand P.I. and Executive Director P.I. and Director Today’s outline • • • • • • • Who we are (NSF ATE Centers of Excellence) Technical curriculum Importance of regular review Alabama (CARCAM) curriculum & process Florida (FLATE) curriculum & process Summary/review Questions/discussion NSF Advanced Technological Education Partners with Industry for a New American Workforce 3 P R O F C U R R I O U T R E S A C U H S I L U D E V E L O N A P M E N T L Outreach Curriculum Professional Development VISION FLATE will be Florida’s leading resource for education and training expertise, leadership, projects, and services to promote and support the workforce in the high performance production and manufacturing community. MISSION To provide a system to educate a highly-skilled employee pipeline for the automotive and advanced manufacturing industries. FLATE COLLEGE NETWORK Broward College Central Florida College Chipola College Daytona State College Eastern Florida State College Florida State College at Jacksonville Florida Gateway College Gulf Coast State College Hillsborough Community College Lake Sumter State College Northwest Florida State College Palm Beach State College Pasco-Hernando State College Pensacola State College Polk State College Seminole State College State College of Florida - Manatee St. Petersburg College Tallahassee Community College CARCAM COLLEGE NETWORK Bevill State Calhoun Central Alabama Drake State Faulkner State Gadsden State Jefferson State Lawson State Northeast State Shelton State Southern Union State Trenholm State Wallace State-Hanceville Who we are - CARCAM • Consortium for Alabama Regional Center for Automotive Manufacturing (CARCAM) – – – – – – A NSF Advanced Technological Education (ATE) Center of Excellence The Only Center in Alabama Hosted by Gadsden State Community College, Gadsden, AL Funded in 2005 & Created AUT Curriculum in 2006 CARCAM Supports Advanced Manufacturing CARCAM works with the Alabama Community College System to standardize and create/update curriculum to meet industry need 9 STUDENT EXPOSURE TO MANUFACTURING STEM/Robotics Camps, etc….. What is manufacturing? 600,000 unfilled high-skill high-wage JOBS Why manufacturing? Source: The Manufacturing Institute Manufacturing Jobs Require Higher Skills How do we ensure curriculum is relevant and rigorous ? Informal and formal review processes Informal Curriculum Review Anecdotal information • Partners/colleagues • Various publications • Internet • Working students College level program reviews Formal Curriculum Review College level program reviews Defined/required process & schedule • • • • Job Task Analysis DACUM Process Modified DACUM Process Curriculum Gap Analysis Model Alignment to national industry credential standards Questions ? /Audience poll!!! Have you participated in a. Dacum b. Modified Dacum c. PCAL d. Gap Analysis e. 2 or 3 of the above f. None of the above ? Desirable Characteristics of Effective Curriculum Review Processes Require Frequency/Regularity of Reviews Identify & Communicate a Formalized Process Involve Industry for Currency & Relevancy Involve Faculty Leaders & Subject Matter Experts Provide Guidance for Updates CARCAM - ALABAMA PROCESSES GAP ANALYSIS SURVEY MODEL Alabama Automotive Manufacturing Technology AS Degree I. General Education – 22 credit hours English/Speech Science I. General Education Social – 15Science - 18 credit hours Math Humanities/Ethics Microcomputer Applications II. AUT Core - 21 credit hours II. Automotive Concepts Lean ET Manufacturing/Safety Core - 18 credit Robotics Electronics/AC/DC Blue Print Reading hours Programmable Logic Controllers III. Specialization Tracks: 21-33 credit hours Drafting Welding Logistics Operations Specialists III. Machining 10 Specialization Tracts – 24 to 27 credit hours Electronics Industrial Automation Total: 64-76 hours CARCAM CURRICULUM GAP ANALYSIS PROCESS • Select Courses and Develop Survey Documents • Distribute Surveys to Select Companies • Review Survey Responses and Input Data Into Plan of Instruction for Analysis • Make Curriculum Changes if Required • Notify Industry of Curriculum Updates/Changes CGA Survey Instrument Review Plans of Instruction (POI) Industry Feedback – AUT100-DC Item 3 1. Power and current calculation should be taught at the 3 KSA 2. Since a small company, KSA for A1.1.1, A1.1.2 and A1.1.3 are at 4 3. Good to see root cause analysis in C1.2 performance objectives Action Taken 1. & 2. – KSA’s are minimum course standards expected of successful completers. Most objectives are taught at a higher level than the KSA assigned but not less than that value. Individual companies may require a higher level of understanding depending on their specific needs. 3. No action required Item 4 Since a small company, KSA for A1.1.1, A1.1.2 and A1.1.3 are at a 4. Action Taken See action taken – Item 3 Item 6 Explain the function of each atomic component structure Action Taken Taught in Module A but not listed as a learning objective CGA Data Results 2011-2014 • • • • 98 Industry Participants Completed Survey 32 Course Plans of Instruction (POI) Reviewed 12 Courses Received Changes to Curriculum 20 Modules Updated Within Courses Unintended Outcomes 2 New Welding Courses Developed 5 Courses Standardized Due to Review CARCAM CGA IMPACT 170 Courses Improved 96 Mfg. Related Courses Standardized 24 New Courses Developed Who we are - FLATE • Florida Advanced Technological Education Center of Excellence for Manufacturing (FLATE) – A National Science Foundation (NSF) Advanced Technological Education (ATE) Center of Excellence – Hosted by Hillsborough Community College, Tampa, Florida and funded since 2004 – FLATE supports all of advanced manufacturing – Florida has a statewide system for curriculum 26 Florida Engineering Technology AS Degree I. General Education – 15 - 18 credit hours English Science Math Social Science I. General Education – 15 - 18 credit hours Humanities II. ET Core - 18 credit hours II. Computer Aided Design Electronics Manufacturing & Materials ET Core -Processes 18 credit hours Quality Mechanics & Instrumentation Safety III. 10 Specialization Tracks: 24 to 27 credit hours Advanced Manufacturing Mechanical Design & Fabrication Energy Systems Electronics III. Alternative 10 Specialization Tracts – 24 to 27 credit hours Biomedical Systems Digital Design & Modeling Digital Manufacturing Industrial Energy Efficiency Advanced Technology Quality 60 semester hours Florida’s Curriculum Review Process FL ACE Department Manufacturing Cluster Program Committee NEW / Revised Curriculum Framework • Manage/oversee the process • Develop 3-year work plan • Identify occupations • Oversee implementation of work plan, timelines, participants, dissemination of results • Develop new program frameworks • Revise/delete existing frameworks • Consolidate duplicative frameworks • Members are educators, industry, regulatory agencies, workforce boards, etc. • Submit consus document to FLDOE for revised frameworks • Defines what an individual needs to know and be able to do • Includes common core standards (for secondary programs) • Defines occupational SOC Codes Florida’s Curriculum Review Process & Players • Manage the process • Develop 3-year work plan • Identify occupations • Oversee implementation FDOE ACE Division of the work plan, Manufacturing Cluster timelines, participants • Prepare final documents for state approval Florida’s Curriculum Review Process & Players Program Committee • Develop new frameworks • Revise/delete existing frameworks • Consolidate duplications • Members are educators, industry, regulatory agencies, workforce boards, other stakeholders, etc. • Submit consensus document to FDOE for revised frameworks Florida’s Curriculum Review Process & Players New / Revised Curriculum Framework • Defines what an individual needs to know and be able to do • Includes common core standards (for secondary programs) • Defines occupations & SOC Codes FL Process and Timeline MARCH First review announcement FDOE APRIL-MAY College/industry teams FDOE & college program defined & lead assigned managers JUNE-AUG Frameworks reviewed AUG-SEPT Consensus document! College/industry teams Lead college/industry team SEPT-OCT Draft framework developed FDOE OCT Final review College/industry teams NOV-DEC Final frameworks FDOE developed FEB-MAR State approval for following State committee academic year Sample Framework Document 2014 – 2015 Florida Department of Education Student Performance Standards Program Title: CIP Numbers: Program Length: SOC Code(s): Engineering Technology 1615000001 60 credit hours 17-3023, 17-3026, 17-3027, 17-3029, 51-4012 The AS degree requires the inclusion of a minimum of 15 credits of general education coursework according to SACS, and it must be transferable according to Rule 6A-14.030 (2), F.A.C. At the completion of this program, the student will be able to: 01.0 Demonstrate knowledge of industrial processes and materials properties--The student will be able to: 01.01 Demonstrate knowledge of current manufacturing processes. 01.02 Demonstrate knowledge of the use of current manufacturing machines, operating systems and mechanisms. 01.03 Estimate manpower needs and skills needed in assembly operations. 01.04 Demonstrate knowledge of the criteria for tool design, maintenance, procurement and handling. 01.05 Demonstrate knowledge of gage design, usage and limitations. 01.06 Analyze and recommend the usage of jigs and fixtures, including effectors and special grippers for automated systems. 01.07 Demonstrate knowledge of processes used to ensure that changes do not negatively impact production or product. 01.08 Demonstrate knowledge of production timing to ensure customer satisfaction and on-time delivery. 01.09 Demonstrate knowledge of time and motion to enhance productivity. 01.10 Make continuous adjustments to equipment and procedures that result in improved productivity. 01.11 Demonstrate knowledge of how raw materials are moved. 01.12 Setup or modify new equipment per engineering specifications and documentations. 01.13 Demonstrate an understanding of the importance and impact of routine maintenance of machines and equipment on operations. 02.0 Generate and interpret computer-aided drawings--The student will be able to: 02.01 Apply current industrial computer aided-drawing practices. 02.02 Construct geometric figures. Sample Framework Framework Document 2014 – 2015 Florida Department of Education Student Performance Standards Program Title: CIP Numbers: Program Length: SOC Code(s): 2014 – 2015 Florida Department of Education Student Performance Standards Program Title: Engineering Technology Engineering Technology 1615000001 CIP Numbers: 1615000001 60 credit hours Program Length: 60 credit hours 17-3023, 17-3026, 17-3027, 17-3029, 51-4012 SOC Code(s): 17-3023, 17-3026, 17-3027, 17-3029, The AS degree requires the inclusion of a minimum of 15 credits of general education coursework according to SACS, and it must be transferable according to Rule51-4012 6A-14.030 (2), F.A.C. At the completion of this program, the student will be able to: 01.0 Demonstrate knowledge of industrial processes and materials properties--The student will be able to: 01.01 Demonstrate knowledge of current manufacturing processes. 01.02 Demonstrate knowledge of the use of current manufacturing machines, operating systems and mechanisms. 01.03 Estimate manpower needs and skills needed in assembly operations. 01.04 Demonstrate knowledge of the criteria for tool design, maintenance, procurement and handling. 01.05 Demonstrate knowledge of gage design, usage and limitations. 01.06 Analyze and recommend the usage of jigs and fixtures, including effectors and special grippers for automated systems. 01.07 Demonstrate knowledge of processes used to ensure that changes do not negatively impact production or product. 01.08 Demonstrate knowledge of production timing to ensure customer satisfaction and on-time delivery. 01.09 Demonstrate knowledge of time and motion to enhance productivity. 01.10 Make continuous adjustments to equipment and procedures that result in improved productivity. 01.11 Demonstrate knowledge of how raw materials are moved. 01.12 Setup or modify new equipment per engineering specifications and documentations. 01.13 Demonstrate an understanding of the importance and impact of routine maintenance of machines and equipment on operations. 02.0 Generate and interpret computer-aided drawings--The student will be able to: 02.01 Apply current industrial computer aided-drawing practices. 02.02 Construct geometric figures. Demonstrate knowledge ... Construct… Prepare… Set up equipment… Analyze… Sample Framework REVIEW Document Sample Framework REVIEW Document This needs clarifying – are they individual or integrated systems? K=Keep as is U=Update per comment D=Delete (no longer relevant) S=New standard per comment B=new benchmark per comment Sample Framework REVIEW Document (2) Summary of A.S. ET Degree 2012-13 Advanced Manufacturing in Florida In Summary Desirable Characteristics of Effective Curriculum Review Processes Require Frequency/Regularity of Reviews Identify & Communicate a Formalized Process Involve Industry for Currency & Relevancy Involve Faculty Leaders & Subject Matter Experts Provide Guidance for Updates Critical Component Active Industry Engagement • • • • • • • • • Involvement in recruitment events Professional development for faculty Provide internships for students; externships for faculty Provide business mentoring Guest speakers Co-author whitepapers Evaluate capstone presentations Participate in panels at conferences Hire graduates Join Us in Pittsburg, PA! July 25-29, 2016 www.highimpact-tec.org Thank you! Marilyn Barger, Ph.D., P.E. Executive Director and P.I. 813.259.6578 barger@fl-ate.org www.fl-ate.org www.madeinflorida.org www.flate.pbwiki.com Beverly Hilderbrand P.I. and Director 256.439.6871 bhilderbrand@gadsenstate.edu www.carcam.org Follow us on Twitter! @CARCAM_AL & facebook.com/1CARCAM This presentation will be posted on FLATE’s wiki: www.flate.pbwiki.com