-

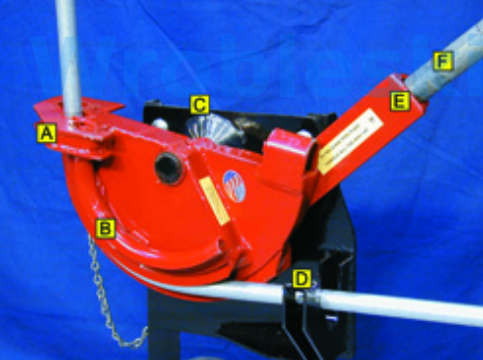

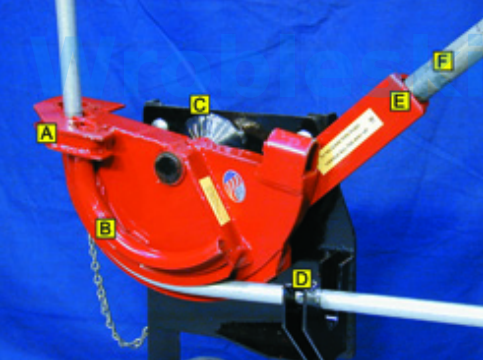

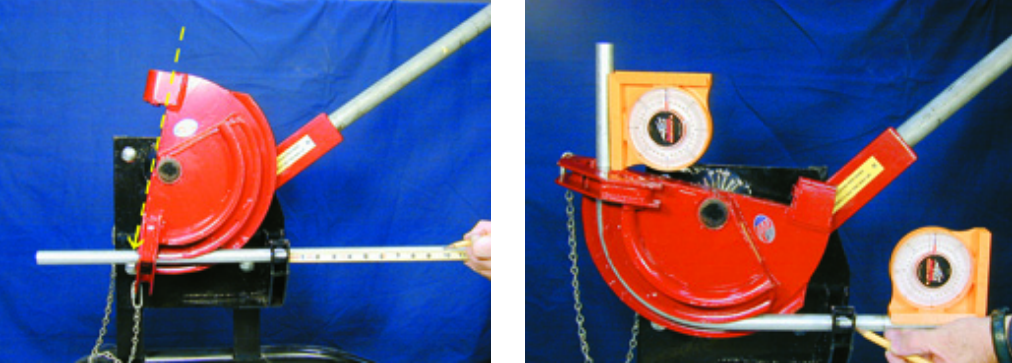

Question 1

Match the name of the bender part or its function with the corresponding letter from the photo.

Options:

Conduit Support

Degree Scale

Extension Handle

Ratchet Handle / Pawl Release

Removable Collar (Hook)

Shoe

The correct answer is:

Conduit Support → D,

Degree Scale → C,

Extension Handle → F,

Ratchet Handle / Pawl Release → E,

Removable Collar (Hook) → A,

Shoe → B

-

Question 2

Match the function of the bender part with the corresponding letter from the photo.

Aligned with take-up mark (Mark 1) =

Can be detached to insert or remove

conduit =

Forms the conduit into the desired shape =

Holds the conduit against the shoe =

Increases leverage =

Must be lifted all the way up to release the conduit =

Not accurate enough for precision conduit work =

The benchmark for measuring travel =

The correct answer is: Aligned with take-up mark (Mark 1) = → A,

Can be detached to insert or remove conduit = → A,

Forms the conduit into the desired shape = → B,

Holds the conduit against the shoe = → A,

Increases leverage = → F,

Must be lifted all the way up to release the conduit = → E,

Not accurate enough for precision conduit work = → C,

The benchmark for measuring travel = → D

-

Question 3

Match the hydraulic bender component with its function.

Carries fluid from the pump to the cylinder

Forms the conduit into the desired shape

Stores extra hydraulic fluid

Holds cylinder and ram in position

Controls fluid pressure and flow

Creates pressure to move the ram

Supports the conduit as it is bent

Drives the shoe

Indicates ram travel

Holds conduit against shoe

Options:

Pipe Collar

Reservoir

Pump

Reservoir

Reservoir

Shoe

Hoses

Pump

Follow bar

Scale

The correct answer is:

Carries fluid from the pump to the cylinder → Hoses,

Forms the conduit into the desired shape → Shoe,

Stores extra hydraulic fluid → Reservoir,

Holds cylinder and ram in position → Yoke,

Controls fluid pressure and flow → Valves,

Creates pressure to move the ram → Pump,

Supports the conduit as it is bent → Follow bar,

Drives the shoe → Piston and Ram,

Indicates ram travel → Scale,

Holds conduit against shoe → Pipe Collar

-

Question 4

Which of the following is not a part that would be found on an electric bender?

a. Control pad

b. Gearbox

c. Motor

d. Ratchet handle

e. Rollers

The correct answer is: Ratchet handle

-

Question 5

The two general categories of hydraulic benders are one-shot and multiple-shot.

Select one:

True

False

The correct answer is 'True'.

-

Question 6

What is the range of sizes of rigid metal conduit that can be bent with a mechanical

bender?

a. 1/2" to 1"

b. 1/2" to 2"

c. 1/2" to 2 1/2"

d. 1/2" to 3"

The correct answer is: 1/2" to 2"

-

Question 7

The common name for a ratcheting mechanical bender is a ? bender.

a. Boston

b. Chicago

c. Detroit

d. Greenlee

The correct answer is: Chicago

-

Question 8

The length of conduit that moves past the conduit support or roller in order to measure

the amount of bend is called ? .

a. gain

b. setback

c. take-up

d. travel

The correct answer is: travel

-

Question 9

? is the distance from the back of a 90° bend to the bending mark, which was aligned

with the front of the hook or collar on the bender.

a. Gain

b. Setback

c. Take-up

d. Travel

The correct answer is: Take-up

-

Question 10

Subtracting the gain from the take-up results in a value called ? , which can be used to

position other bends a specific distance from the back of the stub.

a. gain

b. setback

c. take-down

d. travel

The correct answer is: setback

-

Question 11

The difference in the original length of a piece of conduit and the sum of the stub-up and

leg lengths after a 90° bend is made is called ? .

a. gain

b. setback

c. shrink

d. travel

The correct answer is: gain

-

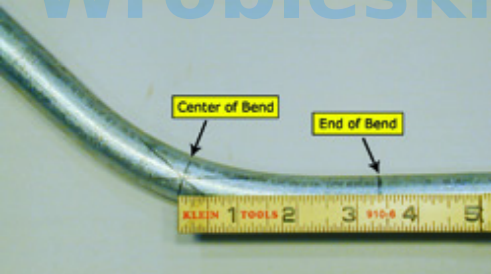

Question 12

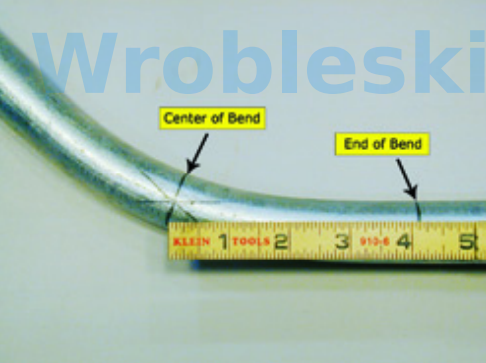

The radius adjustment is the distance between the center of bend and the end of the

bend and is used to move the bend away from the obstruction.

Select one:

True

False

The correct answer is 'True'.

-

Question 13

The stub-up length is equal to the distance from the end of conduit to the bender arrow benchmark pencil mark, plus the ? .

a. bend

b. shrink

c. take-up

d. all of the above

The correct answer is: take-up

-

Question 14

Determining the travel, take-up, gain, setback, and radius adjustment are referred to as ? a bender.

a. balancing

b. calibrating

c. charting

d. documenting

The correct answer is: charting

-

Question 15

In some cases, ? can be used to determine the amount of bend when using a hydraulic bender.

a. charting

b. push-through

c. ram travel

d. set-back

The correct answer is: ram travel

-

Question 16

A method of bending conduit where the conduit is not turned around in the bender during the bending process is the push-through method.

Select one:

True

False

The correct answer is 'True'.

-

Question 17

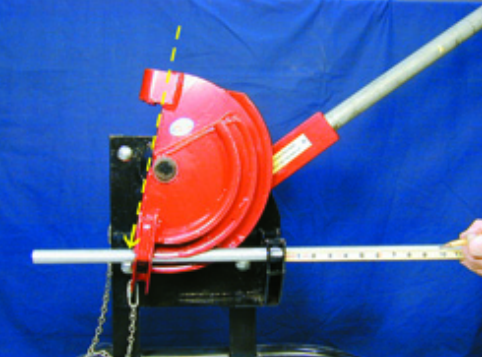

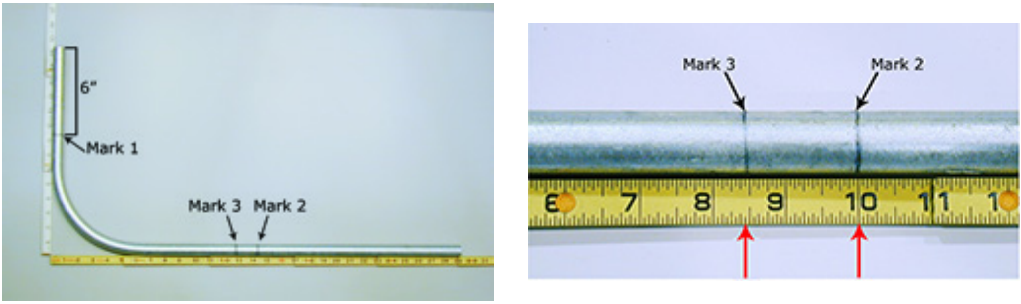

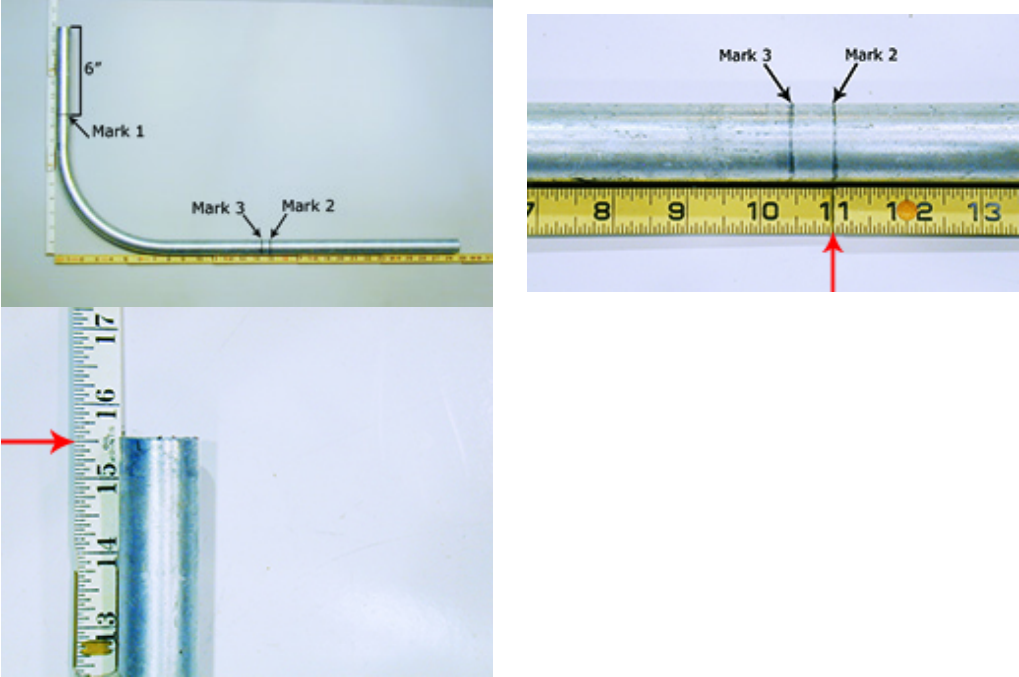

In order to use a mechanical or electric bender with the greatest efficiency and accuracy, it is necessary to know the values for the travel, take-up, gain, setback, and radius adjustment. These values should be determined in the order listed before attempting to use a bender for everyday fabrication work. To determine the various dimensions, scrap pieces of conduit can be used (if available), or a 90° bend can be made on the end of a length of conduit with the expectation that the 90 will be able to be used later on. To begin, a piece (or pieces) of conduit can be measured and marked at a predetermined distance from the end of the conduit. In the photo, two pieces of conduit ( 1/2" and 3/4" rigid) have been cut to 40" in length and marked 6" from the end of the conduits.

What is the conduit mark illustrated in this photo?

a. Mark 1

b. Mark 2

c. Mark 3

d. Mark 4

The correct answer is: Mark 1

-

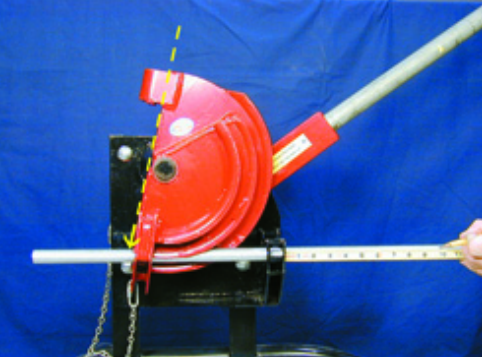

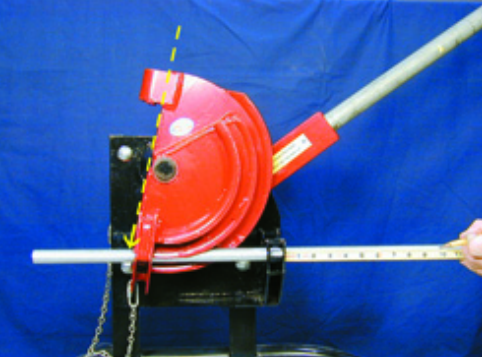

Question 18

Next, the conduit is inserted into the bender and the mark is aligned with the front of the shoe as shown. Keep in mind that in order for the bender chart to be usable by all of the electricians on the job, there must be agreement as to where Mark 1 is to be aligned relative to the collar or hook. In this case, the mark is aligned with the flat front surface of the rotating part of the bender, thereby enabling a worker to sight down the front of the shoe from above, and then adjust the position of the mark until it is just visible at the front of the shoe. Another thing to consider is that the bender may be able to handle multiple conduit sizes

and types, and it may not be practical to chart the bender for all of the possible combinations at the same time.

A mark is being made 10" from the back of the conduit support. What is the designation for this mark?

a. Mark 1

b. Mark 2

c. Mark 3

d. Mark 4

The correct answer is: Mark 2

-

Question 19

Next, the conduit is inserted into the bender and the mark is aligned with the front of the shoe as shown. Keep in mind that in order for the bender chart to be usable by all of the electricians on the job, there must be agreement as to where Mark 1 is to be aligned relative to the collar or hook. In this case, the mark is aligned with the flat front surface of the rotating part of the bender, thereby enabling a worker to sight down the front of the shoe from above, and then adjust the position of the mark until it is just visible at the front of the shoe. Another thing to consider is that the bender may be able to handle multiple conduit sizes and types, and it may not be practical to chart the bender for all of the possible combinations at the same time.

A mark is being made 10" from the back of the conduit support. What will the mark be used to determine?

a. Gain

b. Take-up

c. Setback

d. Travel

The correct answer is: Travel

-

Question 20

Prior to making the mark at 10" from the back of the conduit support, the person making the bend should make sure that:

1) Mark 1 is accurately aligned with the benchmark at the front of the bender.

2) The pawl has been engaged and pressure is being maintained on the conduit.

Select one:

True

False

The correct answer is 'True'.

-

Question 21

The next step in finding the travel for the bender shoe is to advance the bender until a 22 1/2 ° bend is formed.

Select one:

True

False

The correct answer is 'False'.

-

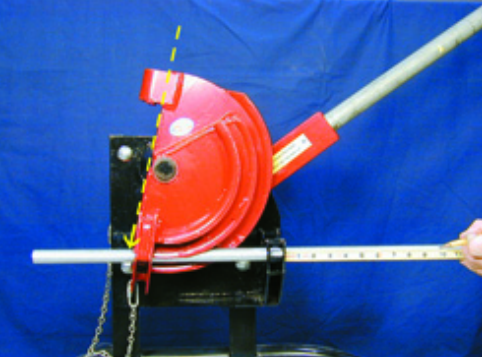

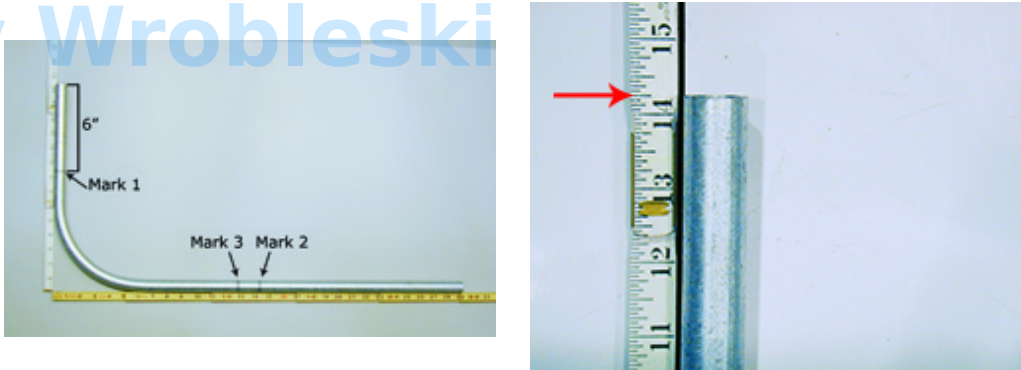

Question 22

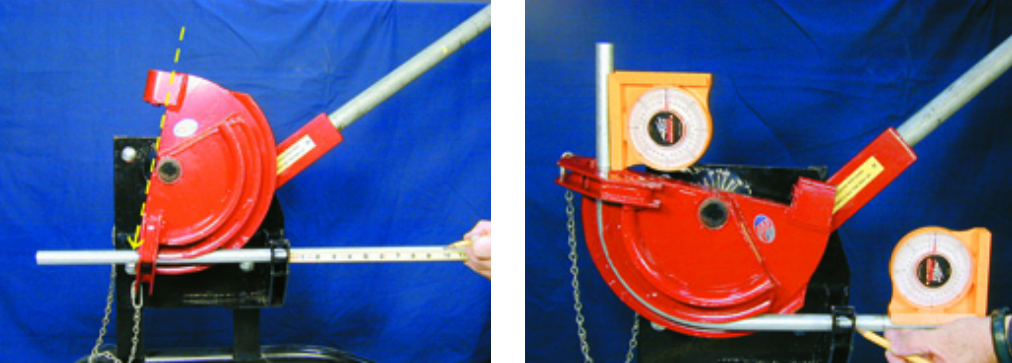

A piece of 1/2" RMC has been bent to 90°. Note that in order for the levels to indicate the degree of bend properly, the weight of the handle must be lifted slightly and the conduit allowed to spring back.

What mark is being placed on the conduit in the photo on the right?

a. Mark 1

b. Mark 2

c. Mark 3

d. Mark 4

The correct answer is: Mark 3

-

Question 23

The distance between this mark and Mark 2 will be added from the original distance that Mark 2 was placed behind the travel benchmark (back of the conduit support).

Select one:

True

False

The correct answer is 'False'.

-

Question 24

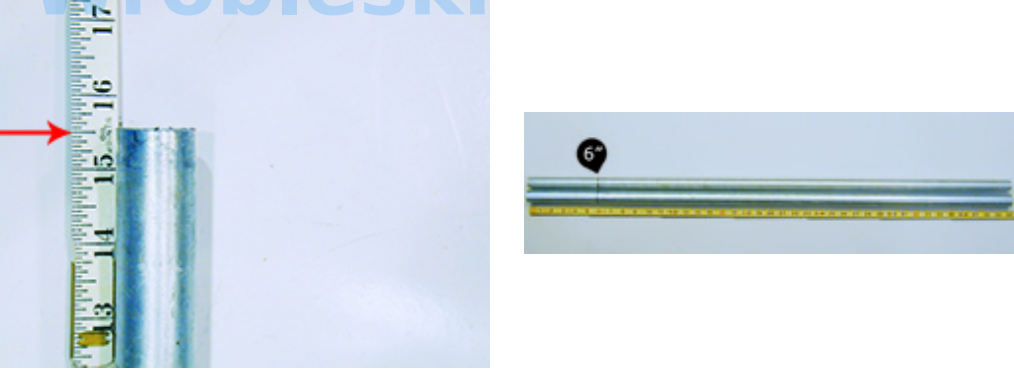

Observing the information contained in the following photos, make the calculations for the travel, take-up, gain, setback, and 45° radius adjustment, and then complete the chart for the 1/2" RMC in the printable bender chart, rounding the values off to the nearest 1/16". Be prepared to show all calculations on a separate sheet of paper.

What is the amount of travel indicated?

Record this value in the appropriate space on

the bending chart.

a. 8 1/4"

b. 8 7/16"

c. 9 1/2"

d. 9 3/4"

The correct answer is: 8 7/16 "

-

Question 25

Calculate the take-up. Record this value in the appropriate space on the bending chart.

a. 8"

b. 8 1/4"

c. 8 1/2"

d. 8 3/4"

The correct answer is: 8 1/4"

-

Question 26

Calculate the gain based upon the dimensions in the photos. Record this value in the appropriate space on the bending chart. (Original length = 40 inches)

a. 3"

b. 3 1/4"

c. 4 1/2"

d. 5 3/4"

The correct answer is: 3 1/4"

-

Question 27

What is the value for the 45° radius adjustment as shown in the photo? (If necessary, review the information in Chapter 4 of the Conduit Bending and Fabrication book on how to find the center of a bend.)

a. 1"

b. 2 3/4"

c. 3 3/8"

d. 3 7/8"

The correct answer is: 3 3/8"

-

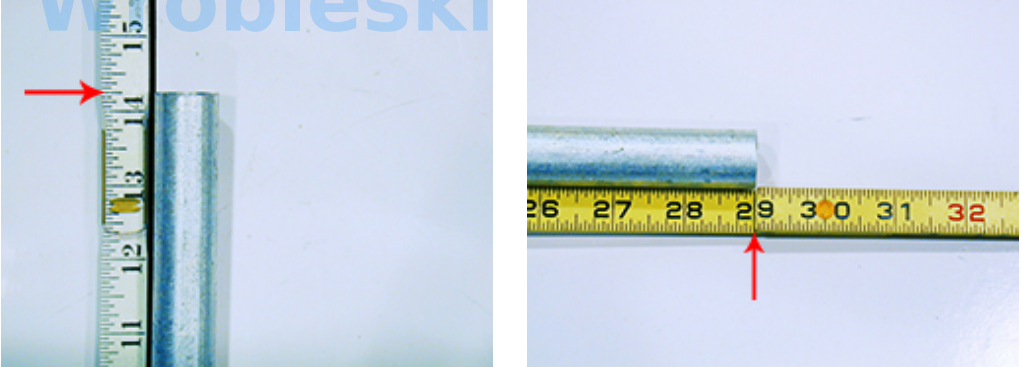

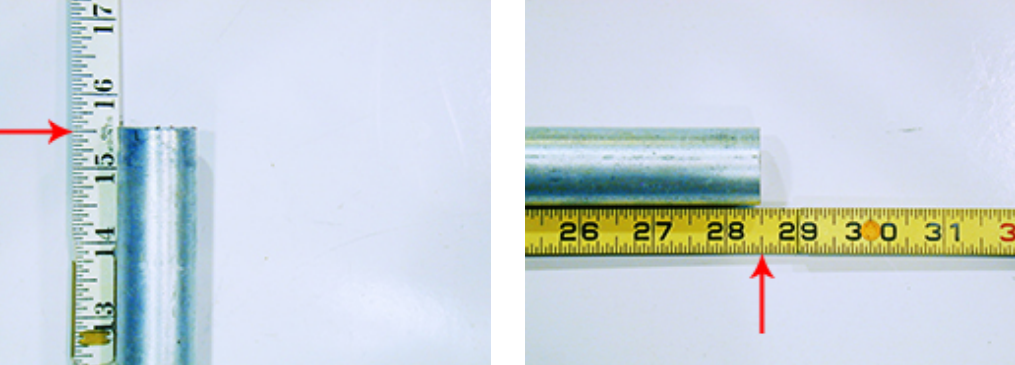

Question 28

Now look at the series of photos for the 3/4" RMC bent with the same bender. Again calculate the values to complete the information for the 3/4" RMC section of the printable bender chart. In this case, Mark 2 was shifted to 11" during the bending process because the travel was more than 10". If this happens to you when trying to chart a bender, simply shift Mark 2 back by an inch or two and then base your travel calculations on the new Mark 2 distance.

What is the 90° travel for this 3/4" RMC? Record this value in the appropriate space on

the bending chart.

a. 8 9/16"

b. 9 7/16"

c. 10 7/16"

d. 11 9/16"

The correct answer is: 10 7/16"

-

Question 29

Calculate the take-up based upon what you see in photo. Answer the question in the form of a decimal. Record this value in the appropriate space on the bending chart.

The correct answer is: 9.5

-

Question 30

Calculate the gain based upon the dimensions in the photos. Record this value in the appropriate space on the bending chart. (Original length = 40 inches)

The correct answer is: 4

-

Question 31

What is the value for the 3/4" RMC 45° radius adjustment as shown in the photo?

a. 1 1/2"

b. 2 3/8"

c. 4"

d. 4 1/8"

The correct answer is: 4 1/8"

-

Question 32

Based upon the information in the bender chart which you created, you will now be given some scenarios which will require you to calculate the lengths and distances for fabricating certain bends.

A 90° bend is to be made in a piece of 1/2" RMC with a stub length of 24 9/16" and a leg length of 41 1/4". The conduit is to be cut and threaded before it is bent. Calculate the total length of conduit needed. Note: The values calculated for this question will be used for additional questions.

a. 61 1/2"

b. 61 3/8"

c. 62"

d. 62 9/16"

The correct answer is: 62 9/16"

-

Question 33

Where will the Mark 1 pencil mark be placed on the 1/2" rigid metal conduit in the photo in order to bend the desired stub-up of 24 9/16"?

a. 12 1/2"

b. 16 5/16"

c. 17"

d. 17 9/16"

The correct answer is: 16 5/16"

-

Question 34

The conduit is inserted into the bender and prepared for bending. Where would a pencil mark be placed to indicate the end of travel for a 90° bend?

a. 6 5/8"

b. 8 7/16"

c. 10 7/16"

d. 11 5/8"

The correct answer is: 8 7/16"

-

Question 35

Where would a mark be placed to indicate where the end of the travel would be if you wished to bend a 15° kick in the 1/2" rigid metal conduit?

a. 1 7/16"

b. 6 5/8"

c. 10 7/16"

d. 11 5/8"

The correct answer is: 1 7/16"

-

Question 36

A 90° bend is to be made in a piece of 3/4" RMC with a stub length of 16 3/4" and a leg length of 32". The conduit is to be cut and threaded before it is bent. Using the gain value that was recorded in the bending chart, calculate the total length of conduit needed.

a. 44 3/4"

b. 46 5/8"

c. 48 7/16"

d. 49 5/8"

The correct answer is: 44 3/4"

-

Question 37

Mark 1 should be placed at 16 3/4" since the ruler is aligned with the take-up value (using the data for 3/4" RMC from the bending chart).

Select one:

True

False

The correct answer is 'True'.

-

Question 38

The 3/4" RMC conduit is inserted into the bender and prepared for bending. Where would a pencil mark be placed to indicate the end of travel for a 90° bend?

a. 6 5/8"

b. 8 3/8"

c. 10 7/16"

d. 11 5/8"

The correct answer is: 10 7/16"

-

Question 39

Where would a pencil mark be placed to indicate where the end of the travel would be if you wished to make a 22 1/2° bend in the 3/4" rigid metal conduit?

a. 1 1/8"

b. 2 1/4"

c. 2 5/8"

d. 3 1/8"

The correct answer is: 2 5/8"

-

Question 40

In the photo a back-to-back 90 has been formed in a piece of 1" RMC. The take-up for the bender is 9 3/4", and the gain is 4 1/8". Calculate the total length of conduit needed.

a. 49 1/8"

b. 49 1/4"

c. 49 3/4"

d. 50 1/8"

The correct answer is: 49 3/4"

-

Question 41

Determine the position of Mark 1.

a. 1 7/8"

b. 2"

c. 2 1/4"

d. 2 7/8"

The correct answer is: 2 1/4"

-

Question 42

Determine the distance between Mark 1 and Mark 2.

a. 18 7/8"

b. 19"

c. 19 1/4"

d. 19 7/8"

The correct answer is: 19 7/8"

-

Question 43

Using the data from the bender chart, calculate the total length of the 3/4" RMC needed to form the back-to-back bend shown in the photo.

The correct answer is: 60 inches

-

Question 44

Determine the position of Mark 1. Answer the question in the form of a decimal.

The correct answer is: 4.5 inches

-

Determine the distance between Mark 1 and Mark 2.

The correct answer is: 26 inches

-

Question 46

Using the data from the bender chart, calculate the total length of the 1/2" RMC needed to form the back-to-back bends shown in the photo. Answer the question in the form of a decimal.

The correct answer is: 81.5 inches

-

Question 47

Determine the position of Mark 1. Answer the question in the form of a decimal.

The correct answer is: 11.25 inches

-

Question 48

Determine the distance between Mark 1 and Mark 2. Answer the question in the form of

a decimal.

The correct answer is: 17.75 inches

-

Question 49

Determine the distance between Mark 2 and Mark 3.

a. 21 7/8"

b. 22"

c. 22 1/4"

d. 23"

The correct answer is: 23"