-

the process of handling waste from the time it's created to when it's disposed of

WASTE MANAGEMENT

-

HEIRARCHY

Source Reduction > Recycling > Treatment > Ultimate Disposal

-

MOST PREFERRED OPTIONS

Avoidance, Reduction, Reuse, Recycling

-

LEAST PREFERRED OPTIONS

Recovery, Treatment, Safe Disposal

-

BARRIERS

Technical Limitations, Lack of Information, Consumer Preferences, Quality Product Decline, Economic Concerns, Resistance to Change, Regulatory Barrier, Lack of Markets, Management Apathy, Resistance to Change, Lack of Awareness of Pollution Prevention Advantages, Dissemination of Confidential Product Information

-

INCENTIVES

• Economic Benefits • Regulatory Compliance • Liability Reduction • Enhanced Public Image • Federal and State Grants • Market Incentives • Reduced Waste-treatment Incentives • Potential Tax Incentives • Decreased Worker’s Exposure • Decreased Energy Consumption • Increased Operating Efficiencies • Competitive Advantage • Reduced Negative Environmental Impact

-

physical, chemical or biological properties have been changed as a result of the introduction of certain substances which render it unsafe for some purposes

Wastewater

-

Caused by degradation of organics under an influence of controlled seed.

𝐵𝑂𝐷5

-

Uses strong oxidizing agents with catalysts and heat to oxidize the wastewater

COD

-

more rapid test of organic components

𝑇𝑂𝐶

-

full strength is contacted with biomass in an apparatus

Continuous Respirometry

-

Heavy metals: lead, mercury, cadmium, copper, arsenic, and nickelNon-metallic salts: nitrates, phosphates, and sulfateschemicals: chlorides,soaps, and selenium

INORGANICS

-

pH of Wastewater that will allow the water to become corrosive.

pH of 6 or below

-

pH of Wastewater that will yield to precipitate formation.

pH of 9 or above

-

neutralize acids and even those formed by metabolism

Alkalinity

-

below 37°C are generally suitable for biological treatment, and even higher temperatures (up to 65°C) are possible with specialized microbes.

Temperature

-

Warm wastewater discharges can worsen the DO situation in receiving waters, making careful management of temperature and oxygen-demanding pollutants vital for maintaining healthy aquatic ecosystems.

Dissolved Oxygen

-

Total solids is the residue remaining from a wastewater dried at 103°C to 105°C. It includes the fractions

SOLIDS

-

A water body becomes overly enriched with nutrients, leading to the plentiful growth of simple plant life

NUTRIENTS AND EUTROPHICATION

-

process by which a body of water becomes overly enriched with nutrients, such as nitrogen and phosphorus, leading to excessive growth of algae and aquatic plants

EUTROPHICATION

-

checks how harmful wastewater is to aquatic life. (refers to the combined toxic effect of all pollutants in wastewater discharges on aquatic organisms, measured through standardized biological tests)

WHOLE EFFULENT TOXICITY

-

Forms a layer on top of the water, hindering oxygen from dissolving and creating an unpleasant sight

OIL and GREASE

-

Pharmaceuticals and endocrine disruptors from personal care products and industrial chemicals pose risks to ecosystems, despite being present in wastewater at very low levels.

EPOCs

-

- Reduction of biodegradable organic substances in the environment- Reduction of nutrient concentration in the environment- Elimination of pathogens - Recycling and Reuse of water

Wastewater Treatment

-

Pollution Prevention Techniques (2)

- Source Reduction- Recycling (on-site and off-site)

-

Source Reduction (2)

- Product Changes (substitution, conservation, product composition) - Source Control

-

[Source Reduction] Source Control (3)

- Input Material Changes (purification, substitution)- Technology Changed (process, equipment, automation, operation settings)- Operation Practices (procedural measures, management practice, material handling, production scheduling)

-

Recycling (on-site and off-site) (2)

- Use and Reuse

- Reclamation

-

[Recycling] Use and Reuse (2)

- return to original process- raw material for another purposes

-

[Recycling] Reclamation (2)

- processed for recovery - processed as by-product

-

TYPES OF WASTEWATER (3)

- Stormwater Runoff- Industrial - Domestic

-

[TYPES OF WASTEWATER] Domestic (2)

- Grey Water- Black Water

-

[Domestic] Grey Water (3)

- Bathroom - Laundry - Kitchen

-

Wastewater discharged from residential, commercial, and institutional sources, containing human excreta, greywater (from sinks, showers), and other domestic waste. It may include pathogens and organic pollutants, requiring treatment before discharge.

SEWAGE

-

The semi-solid material pumped from septic tanks or cesspools, consisting of scum (floating fats/oils), sludge (settled solids), and liquid. Septage is highly organic, contains pathogens, and requires specialized treatment (e.g., chemical conditioning, dilution) before disposal or processing at wastewater plants.

SEPTAGE

-

Untreated wastewater or industrial waste entering a treatment system. In industrial settings, influent may contain pollutants like heavy metals, chemicals, or organic matter, depending on the industry’s processes

INFLUENT

-

Treated or untreated liquid waste discharged from industrial or municipal systems. Industrial effluent often contains pollutants (e.g., heavy metals, chemicals) and requires treatment to meet regulatory standards before release into water bodies.

EFFLUENT

-

A decentralized waste management system that treats and disposes of wastewater at the source (e.g., industrial facility, residential property). Examples include septic tanks, leachfields, or compact treatment units.

ONSITE SYSTEM

-

Centralized waste management where wastewater or industrial effluent is transported to external facilities (e.g., municipal treatment plants, material recovery facilities) for processing.

OFF-SITE SYSTEM

-

can be combined sewers (where wastewater is carried with storm water) or separated sewers.

Conventional sewerage systems

-

on-site system designed to hold blackwater for sufficiently long period to allow sedimentation. It is usually a water tight single storey tank.

Septic Tank

-

refers to all sludge collected and transported from on-site sanitation systems by vacuum trucks for disposal or treatment

Faecal sludge

-

involves removal of contaminants by physical forces

Unit Operation

-

this involves biological and/or chemical removal of contaminants

Unit Process

-

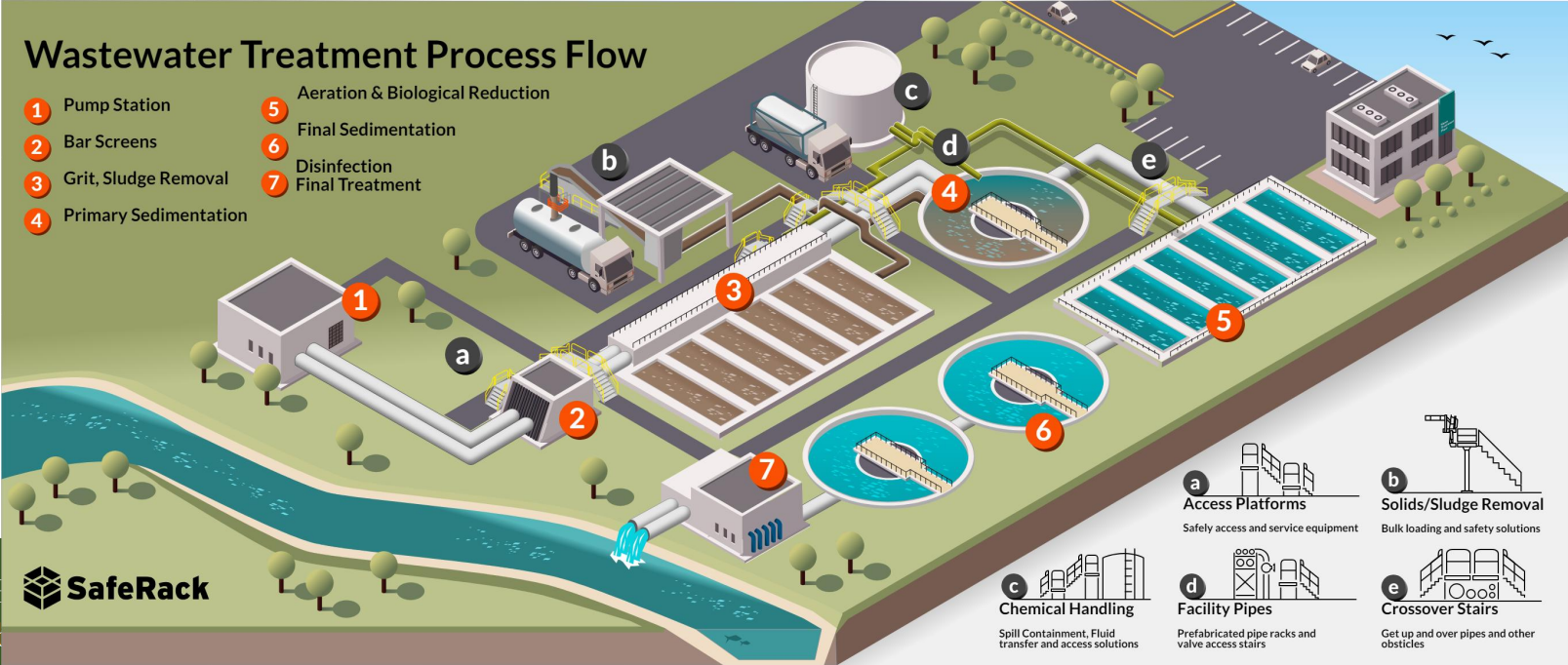

Series of designed unit operations and processes that aims at reducing certain constituents of wastewater to acceptable levels.

Wastewater Treatment Plant

-

Wastewater Treatment Flow

-

Chemicals are added to water to make small particles clump together.

COAGULATION

-

HOW DIFFERENT IS COAGULATION TO FLOCCULATION?

DAPAT ALAM MO YAN!!!!

-

Process in which precipitates must be brought into contact with one another so they can form flocs.

FLOCCULATION

-

Presence of dissolved minerals, primarily calcium and magnesium, but sometimes also iron and manganese.

HARDNESS

-

Reduces water hardness by replacing hardness-causing minerals like calcium and magnesium with sodium ions.

ION EXCHANGE SOFTENING

-

Small clusters of particles that form when suspended solids in water clump together

Flocs

-

Required process prior to subsequent treatment when surface water contains high turbidity

SEDIMENTATION

-

Large tanks or ponds designed to slow down the flow of water, allowing gravity to settle out suspended solids like dirt, grit, and flocs, thus clarifying the water

SEDIMENTATION BASINS

-

Crucial process that removes suspended solids, contaminants, and other impurities from wastewater generated by industrial activities,.

FILTRATION

-

Used in water treatment to kill pathogens present in water that would cause mild to fatal illness if ingested

DISINFECTION

-

Semi-solid mixture of solids and liquids, often containing organic matter and other impurities, that is removed from wastewater during treatment processes

SLUDGE

-

Process concentrates the sludge by removing a portion of the liquid, making it thicker.This is often done using gravity settling

THICKENING

-

The goal is to make the sludge less odorous and less likely to decompose further.

STABILIZATION

-

Dewatering further reduces the liquid content of the sludge, making it a drier, more solid material.

DEWATERING

-

Drastically reduces the volume of the sludge by converting the organic solids into stable forms through chemical processes like wet oxidation (using chemicals to oxidize the organic matter in a wet environment) or incineration (burning the sludge). This is often used when disposal space is limited

REDUCTION

-

SLUDGE DISPOSAL

1. Ultimate Disposal 2. Land Spreading 3. Landfilling 4. Dedicated Land Disposal (DLD) 5. Utilization 6. Sludge Disposal Regulations

-

Designed for high-quality water sources, typically groundwater. They employ specific treatments like disinfection, corrosion control, fluoridation, and mineral removal (iron/manganese, softening) rather than extensive purification

LIMITED PLANTS

-

Coagulation plants treat surface water sources like rivers and lakes, which typically have more impurities than groundwater

COAGULATION PLANTS

-

Used to treat waters having a high hardness level (calcium and magnesium), typically groundwater

SOFTENING PLANTS

-

PHYSICAL PROCESS WASTEWATER TREATMENT

- Screening- Comminution - Flow equalization

- Sedimentation - Flotation - Granular- medium Filtration

-

CHEMICAL PROCESS WASTEWATER TREATMENT

- Chemical precipitation - Adsorption - Disinfection - Dechlorination

-

BIOLOGICAL PROCESS WASTEWATER TREATMENT

- Activated sludge process - Aereted lagoon - Trickling filters - Rotating biological contactors - Pond stabilization - Anaerobic digestion

-

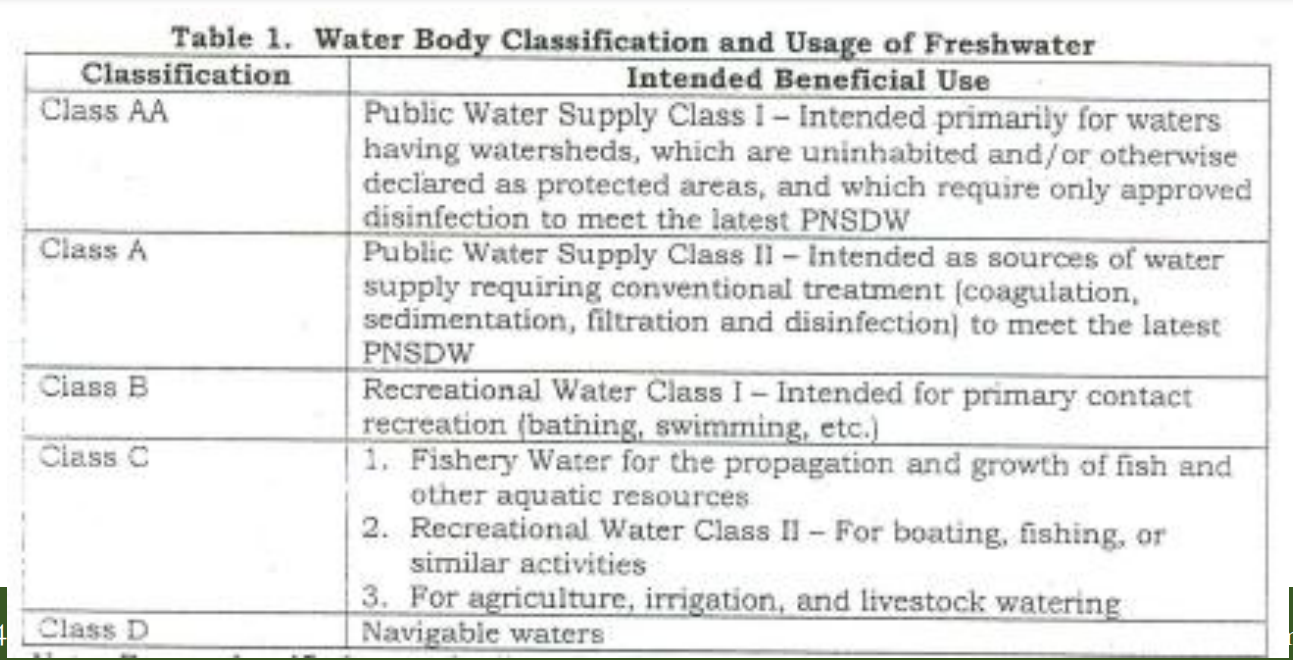

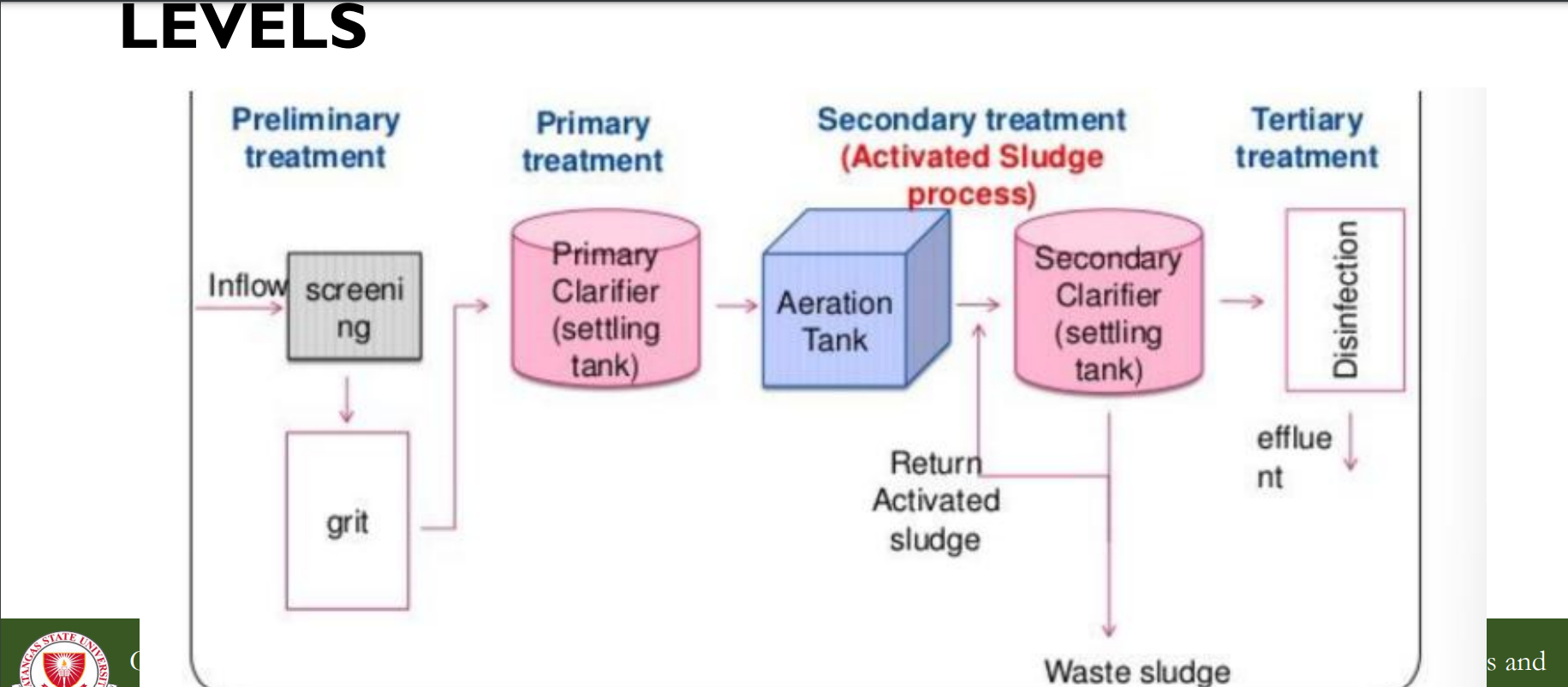

WASTEWATER TREATMENT LEVELS

-

hazardous not because of the composition of the wastes but by virtue of process that produced them, the same is true for the non-hazardous absolute

absolute hazardous

-

Not Based on its composition but because the process that created it is known to produce only non-hazardous waste.

absolute non-hazardous

-

can either be non-hazardous or hazardous depending on the waste composition

mirror entries

-

further assessment cannot change the classification (ex. coal tar)

Absolute Hazardous (AH)

-

waste is non-hazardous without any further assessment (ex: sand and stones)

Absolute non-hazardous (AN)

-

contains hazardous substances exceeding limit for a hazard statement code (ex: soil and stones)

mirror hazardous (MH)

-

contains hazardous substances below concentration limit for a hazard statement code (ex: soil and stones)

mirror non-hazardous (MH)

-

[WASTE GENERATOR] Chemical Manufacturers (5)

- Acids and Bases - Spent solvents - Reactive waste - Waste water - Organic constituents

-

[WASTE GENERATOR] Printing Industry (5)

- Heavy metal solution - Waste inks - Solvents - Ink sludge - Heavy metals

-

[WASTE GENERATOR] Vehicle maintenance shop (3)

- Paint waste - spent solvents - acids and bases

-

• it is non-toxic • Biodegradable • has high concentrations of Biological Oxygen Demand (BOD) and suspended solids (SS)

FOOD INDUSTRY

-

The contamination of waste streams includes the gasification products such as naphthalene, benzene, anthracene, ammonia, phenols, cyanide, cresols along with a variety of more complex organic compounds collectively called polycyclic aromatic hydrocarbons

IRON AND STEEL INDUSTRIES

-

A volatile, white, crystalline aromatic hydrocarbon. It's known for its distinct smell

Naphthalene (C10H8)

-

A clear, colorless, highly flammable liquid with a sweet odor

Benzene (C6H6)

-

A solid polycyclic aromatic hydrocarbon (PAH)

Anthracene (C14H10)

-

A colorless gas with a pungent odor

Ammonia (NH3)

-

A group of organic compounds, with phenol being the simplest

Phenols (C6H5OH)

-

Wastewater from the metal mines and ore recovery plants are unavoidably contaminated by the minerals in the native rock formations

MINES AND QUARRIES

-

The pollutants generated at battery manufacturing plants includes lead, manganese, mercury, nickel, chromium, cobalt, copper, cadmium, cyanide, iron, oil and grease, silver and zinc

BATTERY MANUFACTURING

-

Many electric power plants discharge wastewater with significant amounts of metals such as lead, cadmium, chromium, and mercury, as well as arsenic, nitrogen compounds (nitrites and nitrates), and selenium.

ELECTRIC POWER PLANTS

-

• Pollutants generated by textile mills include oil and grease, BOD, sulfide, phenols and chromium • Insecticide residues in fleeces are particular problem in treating wastewater generated in wool processing.

TEXTILE INDUSTRIES

-

Pollutants discharged at the petroleum refineries and petrochemical plants include the conventional pollutants (BOD, oil and grease, COD, SS), ammonia, phenols, sulfides, and chromium.

PETROCHEMICAL INDUSTRIES

-

Plants that bleach wood pulp for the manufacturing of paper may generate dioxins (including 2,3,7,8- TCDD), chloroform, furans, COD, and phenols. Stand-alone paper mills using an imported pulp may only need simple primary treatment, such as dissolved air flotation or sedimentation

PAPER & PULP INDUSTRIES

-

This is the foundational law governing the ownership, appropriation, utilization, exploitation, development, conservation, and protection of water resources. It establishes the principle of "beneficial use" and outlines water rights and permits.

The Water Code of the Philippines (Presidential Decree 1067)

-

This act focuses on water quality management, aiming to protect water bodies from pollution. It sets water quality standards, establishes Water Quality Management Areas (WQMAs), and promotes wastewater treatment and pollution prevention.

The Clean Water Act (Republic Act 9275)

-

DENR Administrative Order 2016-08