Introduction

advertisement

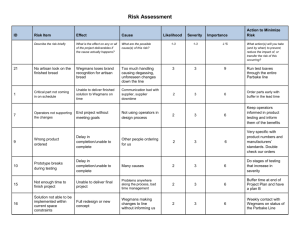

WEGMANS 2009-2010 PROJECTS Matt Syska, Industrial & Systems Engineering Andreana Crance, Industrial & Systems Engineering WEGMANS 2009-2010 PROJECT DOWN-SELECT Wegmans would like to sponsor 4 projects for AY20092010 Project readiness packages have been completed for Cheesecake Pan Process Improvement and Ergonomics and Design of Tumbler Transport DPM FINAL PROJECT PRESENTATION P10711 – WEGMANS - ERGONOMICS AND DESIGN OF TUMBLER TRANSPORT Matt Syska, Industrial & Systems Engineering PROJECT INFORMATION Project Name Wegmans - Ergonomics and Design of Tumbler Transport Project Number P10711 Project Family R09170 Track Modern Food Processing and Bakery Technology for Lean Production Systems Start Term 2009-1 End Term 2009-2 Faculty Guide Dr. John Kaemmerlen (ISE) Technical Lead Phil Bryan Primary Customer Wegmans Culinary Innovation Center, Scott Young MISSION STATEMENT Product Description /Project Overview The aim of this project is to improve the meat marinade tumbler transport in the Wegmans Culinary Innovation Center. Currently, meat is marinated in 2000 lb. capacity tumblers, dumped into 300-600 lb capacity vats, and then transferred into a vacuum pack machine. The current process suffers from many efficiency and ergonomic issues. The overall outcome of the project is to identify and implement process improvements in order to increase efficiency and safety of the workers. Key Business Goals/Project Deliverables The primary business goals of this process change is to: Create standard work processes for meat tumbler transport Utilize workers’ time in a more efficient way Improve overall efficiency of facility in order to make a greater profit Improve safety conditions for all workers Primary Market /Project Opportunities Wegmans Culinary Innovation Center in Rochester, NY Secondary Market /Project Opportunities Similar Wegmans production facilities Stakeholders Wegmans Culinary Innovation Center in Rochester, NY Scott Young and Wegmans’ engineering group Culinary Innovation Center workers whom are effected by the changes Wegmans Distribution Center Community Community that purchases the products WEGMANS CULINARY INNOVATION CENTER $36 million 53,000 sq. ft. addition to meat shipping facility.* Opened early 2009. Central kitchen for Wegman’s in-house brands of soups, sauces, and raw materials used for fresh prepared food. Pre-packaged marinated meat is processed here. *http://www.democratandchronicle.com/article/20090313/BUSINESS/903130318/1001 CURRENT PROCESS Image Sources: http://www.democratandchronicle.com/apps/pbcs.dll/gallery?Site=A2&Date=20090312&Category=multimedia03&ArtNo=903120804&Ref=PH&Params=Itemnr=1 http://www.mpbs.com/resources/contentfiles/mpbs/catalog/products/stainless-steel-mobil-poultry-table/image/10399%20(W).jpg http://www.vacuums365.com/uploaded_images/vacuum-packaging-machine-717063.jpg AFFINITY DIAGRAM – RAW DATA FROM CUSTOMERS AND STAKEHOLDERS Lean No Standardization Safety Ergonomics Concerns Material Handling Transport of raw materials Layout Design Worker Relations Sanitary Requirements New Equipment More efficient set ups Strict handling standards Cost effective Manual process operation improvements Easily cleaned High Volume, High Mix of products Noise Issues Mixing Loading/Unloading Procedures Preventative Procedures Messy Process Improvement Must meet health code Tumbler outpaces packaging machine Pinch Problems Splashing Problems Labor Effeciency Savings Food Safety Changeover Problems Back Injuries 2000 lbs loads Ease of Use Eye Protection Environmentally friendly OBJECTIVE TREE – WHY DOES THE CUSTOMER NEED THIS PRODUCT? This Product or Process Needs to … Lean Processes Improve Loading/Unloading Procedures Balance the Line Safety/Sanitation Proper utilization of resources Ensure safety of workers Material Handling Handle variety of materials Make product movement less messy Stop problems before they occur Ensure Safety of Food Layout Stop splashing from occurring Efficiently use limited amount of space Enable further expansion Cost effective changes FUNCTION TREE – WHAT DOES THIS PRODUCT NEED TO DO? Improve Ergonomics and Design of Tumbler Transport at Wegmans Culinary Innovation Center Lean Reduce time to load/unload transport by 25% Able to be sized up due to high demands Safety Perform to the bottleneck Reduce risk of long term ergonomic injuries by 50% Material Handing Be flexible in design to accommodate 30 different products Eliminate need to wipe packaging area to prevent leakers Be proactive in solving safety problems – report any issues Meet strict food safety standards Layout Prevent splashing from occurring during transport Improve flow of goods and people Create an intuitive and standardized layout Be cost effective HOUSE OF QUALITY TARGET SPECIFICATIONS Metric # Metric Importance Units Measure of Success 1 Transport Time 1 Minutes/Seconds Reduce by 25% 2 Ergonomic Risk 1 NIOSH Lifting Index / Snook Maximum Acceptable Weight Reduce by 50% 3 Employee Utilization 1 % Value Added Labor Improve by 35% 4 Equipment Utilization 2 % Utilization Improve by 10% 5 Product Yield 2 % of product without defects Improve by 10% 6 Wegmans Return on Investment 1 $ ROI in 3-5 years STAFFING REQUIREMENTS Name Discipline Role / Skills Prof. John Kaemmerlen Industrial & Systems Engineering Professor Faculty Guide, Will work closely with the team on an ongoing basis to facilitate success. Phil Bryan Product Development Expert Technical Consultant/TA, Will provide discipline technical support on an intermittent basis. Matthew Syska IE Project Lead for Wegmans Ergonomics and Design of Tumbler Transport Project. Keep project on schedule and within budget constraints. Will also help other IE’s during analysis and implementation stages. TBD Student IE Will be responsible for analyzing data collected as well as implementing changes into the current facility. Will also help document procedures and champion process change. TBD Student IE Ergonomics expert. Will analyze the workspace and recommend changes. These recommendations will be incorporated into the entire design. TBD Student ME Will be responsible for design/spec of new vats to be incorporated into marinade line. Will also be responsible for any manufacturing if applicable. Will also help with data collection. TBD Student ME Will be responsible for design/spec of new vats to be incorporated into marinade line. Will also be responsible for any manufacturing if applicable. Will also help with data collection. INTELLECTUAL PROPERTY CONSIDERATIONS All work to be completed by students in this track is expected to be released to the public domain. Students, Faculty, Staff, and other participants in the project will be expected to release rights to their designs, documents, drawings, etc., to the public domain, so that others may freely build upon the results and findings without constraint. Some Wegmans data used in the project may be proprietary information that cannot be release in the public domain. PRELIMINARY WORK BREAKDOWN STRUCTURE Person Week 0 -> 1 Tasks Week 1->2 Tasks Week 2->3 Tasks Matthew Syska – IE (Project Lead) Prepare for first team meeting Contact Wegmans to set-up tour for rest of group members Attend Wegmans safety training Visit Wegmans facility Finalize SD I plan Meet with line workers to discuss their concerns Collect Data Work with ME’s for design work IE (Lean) Get familiar with project Visit Wegmans for tour Attend Wegmans Safety Training Visit Wegmans facility Create data collection plan Meet with line workers to discuss their concerns Collect Data Start data analysis IE (Ergonomics) Get familiar with project Visit Wegmans for tour Attend Wegmans Safety Training Visit Wegmans facility Create plan for ergonomic analyses Meet with line workers to discuss their concerns Collect Data Create current state ergonomic assessment ME Get familiar with project Visit Wegmans for tour Attend Wegmans Safety Training Visit Wegmans facility Study current process and look into current solutions Meet with line workers to discuss their concerns Collect Data Create preliminary solution concepts ME Get familiar with project Visit Wegmans for tour Attend Wegmans Safety Training Visit Wegmans facility Study current process and look into current solutions Meet with line workers to discuss their concerns Collect Data Create preliminary solution concepts REQUIRED RESOURCES Name Source Description Available People Prof. John Kaemmerlen RIT Faculty Guide Yes Phil Bryan RIT Technical Consultant Yes Scott Young Wegmans Manufacturing Engineering Manager Yes Chris Isaacson Wegmans Industrial Engineer Yes Wegmans CIC Team Leaders Wegmans CIC Team Leaders Yes Wegmans CIC Team Members Wegmans CIC Team Members Yes Environment Access to Wegmans CIC Wegmans Where project will be completed Yes Senior Design Center RIT Group Meetings / Project Space Yes Equipment IE/ME Computer Labs RIT Design Work Yes KGCOE Manual Machine Shop RIT Fabrication Yes Brinkman Lab RIT Fabrication Yes RISK ASSESSMENT Description of Risk Possible Consequences Probability of Risk (H/M/L) Severity of Risk (H/M/L) Overall Risk Contingency Plan Member of team not available for a few weeks Possible gap in completed work H M M Other team members should be aware of what other people are working on and be prepared to pick up slack if necessary Member of team drops out of SD Missing work, possible lack of a particular skill set L H M Other team members will have to pick up slack and make do with the team members that are left Ordered parts do not arrive in time Completion of project in jeopardy M M M Always have a backup plan when ordering less common items. Catastrophic failure of design near end of term Completion of project in jeopardy L H L Have well document designs so things can be remade CIC employees resist change Cannot implement solutions H M M Make employees part of the process change process to increase chances of success. Team member allergic to certain ingredients in CIC Cannot tour/ collect data/ implement L M L Team member will have to complete only tasks outside of facility and rely on pictures / description of process Wegmans cuts funding to the project midway through Cannot complete project L H M Finish up project in “as-is” state, possible finish up without any purchasing. QUESTIONS? P10712 – CHEESECAKE PROCESS IMPROVEMENT Andreana Crance - IE Wegmans – Cheesecake Process Improvement PLANNING STAGE The mission for the cheesecake process improvement is to increase the efficiency and effectiveness of cheesecake production in order to meet customer demand in both quantity and quality of the cheesecakes. MISSION STATEMENT Goal: •Reduce cycle time •Reduce movement distance •Increase throughput to meet market demand •Enable more automated work PROJECT RELEVANCE Wegmans: Enables the production managers to more effectivley use workers’ time Standard work will reduce defects Other large-scale bakeries: More efficient work flow will reduce total cost of cheesecakes RIT MSD Future Projects: Process improvement to reduce production cost will be a popular and demanding topic in years to come STAFFING REQUIREMENTS Name Discipline Role/Skills Professor John Kaemmerlen IE Faculty Guide, Will work closely with the team on an ongoing basis to facilitate success. His background is in LEAN manufacturing and will continually aid the team in thinking with LEAN processes. Phil Bryan ME Faculty Consultant, Will provide discipline technical support on an intermittent basis. Has vast knowledge of product development and will aid the project team in going through the correct process of thinking to efficient and effective. Andreana Crance IE Project manager for the Wegmans Cheesecake Improvement Process. Ensure the proper completion of all tasks with respect to efficiency, quality and cost effectiveness. The project lead will also resolve any ergonomic and human factors issues within the process. Name Discipline Role/Skills TBA (2) IE •Study, define and begin implementing LEAN changes to the Cheesecake making process. •Should be interested in Production Control and LEAN manufacturing, with a background in either one. •Sucessfully gather the required data and apply it to the knowledge learned in class to improve the cheesecake processing line. •focus the layout and facility planning for the cheesecake process. •facilities planning, CAD work •work closely with the student doing the core production control work. TBA (2) ME •Collect data, gather specific customer needs, design and implement a crumbing tool to alleviate amount of man power needed for cheesecake making process. •closely work with customer and bakery workers to produce a usable product. •proficient in CAD modeling, manufacturing processes and procedures, •mindful of an easily manufactured solution that meets health code standards. PRELIMINARY WORK BREAKDOWN STRUCTURE Person Week 0 > 1 Tasks Week 1 > 2 Tasks Week 2 > 3 Tasks Andreana Crance (Project Lead) •Schedule any required training for MSD group •Plan and schedule group meetings •Update EDGE Website to reflect current plans •Get familiar with cheesecake process •Get familiar with cheesecake process •Begin talking to Wegmans Bakery employees to uncover any safety concerns •Collect data on injuries •Collect data on ergonomic concerns (lifting, etc) •Work with other Ies to determine how to design the problems out ME ( 2 ) •Attend any training sessions •Attend group meetings •Get familiar with cheesecake process •Gather data on current crumbing process •Look into quality issues that could be associated with the crumbing process •Preliminary crumbing concept •Research material types •Work with IEs to determine NIOSH lifting standards •Look into weight capacity IE ( 2 ) •Attend any training sessions •Attend group meetings •Get familiar with cheesecake process •Make CAD layout of current process and layout •Begin collecting data on entire process •Communicate with bakery workers for any input for improvements •Analyze data to gather LEAN/Six Sigma order quantities / production rates •Determine optimal production and people flow •Research what process changes will affect outside of the cheesecake process REQUIRED RESOURCES People Environment Equiptment Professor John Kaemmerlen – Faculty Guide Swipe Access to Wegmans Bakery Facility Factory CAD Software Scott Young – Wegmans – Customer Senior Design Lab Space Machining Equiptment Chris Isaacson – Wegmans – IE Main POC Access to ME and IE Labs Phil Bryan – J & J – Technical Lead Access to Manufacturing Lab * Project Budget not set due to the nature of the project (process improvement) – but budget set for design work must be justified. Wegmans – Cheesecake Process Improvement CONCEPT DEVELOPMENT AFFINITY DIAGRAM Material Handling Worker Relations Health Requirements New procedure Easier process Easy to clean Customizable Solution Storage Utilization Less manual processes New crumbing equiptment Small space to work with Overall process improvement Worker Safety Cost effective Efficient use of time Lean Safety Worker Effeciency Ergonomics Storage issues Standard Work for employees Current “messy” process Pans stored everywhere Standard Process Standardized Product Storage Issues Bottleneck (& resource) usage Scalable (growth) Tunnel Oven Issues Increase throughput Decrease time tunnel oven is idle Easily replaceable solution Layout Design Reduce overall procss time OBJECTIVE TREE Wegmans would like to improve the cheesecake making process because they must continually improve their market strategy to reduce production and manufacturing costs while still meeting the quality expectations of the customer. Improve Cheesecake Making Process Lean Processes Storage issues associated with pans Safety Low utilization of bottleneck Low worker efficiency No standard work Ergonomic concerns of employees Hazards due to storage issues Worker Relations Long overall process time Not an intuitive process Very manual process Create standard product Layout Material Handling Long crumbing process Low throughput of process Heavy training for new employees Not effecienct Not cost effective FUNCTION TREE Wegmans would like to improve the process in order to make the product more standard and the production more efficient and safe for the employees. Function Tree – Cheesecake Process Improvement Lean Processes Reduce max # employees by 3 employees Create standard work instructions Safety Reduce # of pans by 30%* Worker Relations Design tool to aid crumbing task Design a more intuitive process Design out 80% of employee ergonomic concerns** Utilize bottleneck to 80% of it’s full capacity Layout Create a more efficient workflow Reduce process time and movement by 25% *** HOUSE OF QUALITY TARGET SPECIFICATIONS (STEP 1) Metric Metric Number Importance Units 1 Average botleneck utilization 1 % per year 2 # of injuries 1 Number per year 3 Material travel distance 1 Feet 4 Average throughput of process 2 Average product per year 5 Floor space occupied 1 Square feet 6 Yield 2 Product per year 7 # employees on crumbing task 1 Employees 8 New employee training 3 Hours per year This is a great way to measure the success of the project!!! RISK ASSESSMENT SO … HOW WILL WE KNOW IF WE’RE SUCESSFUL? Using the Function Tree: Reduce travel time by 40% Reduce process time by 25% Reduce maximum number of employees by 30% (3 employees) Measuring success using the Specifications noted Floor space occupied (feet) Material travel distance (feet) Yield percentage QUESTIONS?