Combustion Overview - Florida Institute of Technology

advertisement

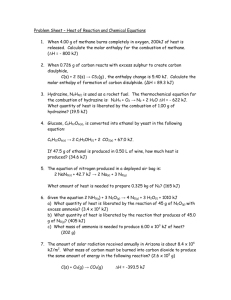

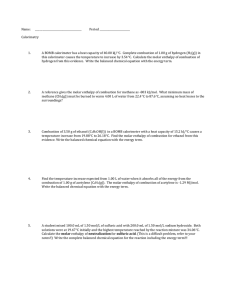

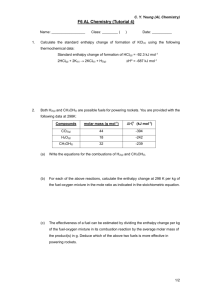

MAE 5380: Advanced Propulsion Part 1: Introduction and Chemical Equilibrium Mechanical and Aerospace Engineering Department Florida Institute of Technology D. R. Kirk 1 COMBUSTION FUNDAMENTALS Thermodynamics • Energy Balance • Flame Temperature Combustion Technology Fluid Mechanics • Flame Propagation • Laminar / Turbulent • Diffusion • Atomization • Combustor Aerodynamics Chemistry • Stoichiometry • Equilibrium • Kinetics • Emissions and Pollutants • Rapid oxidation generating heat • Slow oxidation accompanied by relatively little heat and no light • Combustion transforms energy stored in chemical bonds to heat that can be utilized in a variety of ways 2 Key Combustion Concepts 1. Thermochemistry and Thermodynamics 2. Chemical Kinetics 3. Explosive and General Oxidative Characteristics of Fuels 4. Premixed Flames 5. Diffusion Flames 6. Ignition 7. Detonation 8. Emissions and Pollutants 3 1. THERMOCHEMISTRY • Combustion stoichiometry and thermodynamics – Balance of chemical equations – Lean, stoichiometric, and rich fuel-to-air mixtures – 1st Law of Thermodynamics and enthalpy of combustion • How hot is a flame? (usually 2,000-2,500 K) • Known Stoichiometry + 1st Law → Adiabatic Flame Temperature • Chemical equilibrium: 2nd Law of Thermodynamics – Important in fuel-rich combustion – Stable species at ambient conditions begin to dissociate when T > 1,250 K – Dissociation lowers flame temperature – Solution technique: Minimize Gibbs Free Energy, G=H-TS • Known P and T + Equilibrium Relations → Stoichiometry • Adiabatic combustion equilibrium • Equilibrium + 1st Law → Adiabatic Flame Temperature and Stoichiometry 4 2. CHEMICAL KINETICS • Equilibrium chemistry assumes that T & P are constant for a sufficiently long time for system to reach steady-state • While equilibrium chemistry lends insight into factors that control pollutant formation, greater understanding requires study of rates at which competing reactions proceed • Example: – If f ↓ then T ↓ and [NO] ↓ – BUT for f ↓, hydrocarbon oxidation is slow – For finite combustor length emissions of CO and unburned hydrocarbons can ↑ • Understanding developed from basic kinetic theory → Arrhenius form • Endothermic and Exothermic reactions (forward and backward) • Simplified kinetics vs. detailed mechanisms 5 3. EXPLOSIVE AND GENERAL OXIDATIVE CHARACTERISTICS OF FUELS • • • Explosion: very fast reacting systems (rapid heat release or pressure rise) In order for flames to propagate (deflagrations or detonations), reaction kinetics must be fast, i.e., mixture must be explosive Example H2+O2, y=1 T=500 ºC P=1 atm • At P=1 atm, NO EXPLOSION • If P is lowered to a few % of 1 atm: EXPLOSION • If P is raised to 2 atm: EXPLOSION • What are explosive limits? • Note that explosive limits are not flammability limits – Explosion limits are P & T boundaries for a specific fuel-oxidizer mixture ratio that separate regions of slow and fast reaction – Flammability limits are specify lean and rich fuel-oxidizer mixture ratio beyond which no flame will propagate 6 HINDENBURG: MAY 6, 1937 7 4. COMBUSTION MODES AND FLAME TYPES • Combustion can occur in flame mode – Premixed flames – Diffusion (non-premixed) flames • Combustion can occur in non-flame mode • What is a flame? – A flame is a self-sustaining propagation of a localized combustion zone at subsonic velocities • Flame must be localized: flame occupies only a small portion of combustible mixture at any one time (in contrast to a reaction which occurs uniformly throughout a vessel) • A discrete combustion wave that travels subsonically is called a deflagration • Combustion waves may be also travel at supersonic velocities, which are called detonations • Fundamental propagation mechanisms are different in deflagrations and detonations 8 4. LAMINAR PREMIXED FLAMES • Fuel and oxidizer mixed at molecular level prior to occurrence of any significant chemical reaction Flame color gives indication of temperature Not quite red: T~500-550 ºC Dark red: T~650-750 ºC Bright red: T~850-950 ºC Yellowish red: T~1050-1150 ºC Not quite white: T~1250-1350 ºC White: T > 1450 ºC 9 4. LAMINAR PREMIXED FLAMES 10 PREMIXED FLAMES • Fuel and oxidizer mixed at molecular level prior to occurrence of any significant chemical reaction 11 APPLICATION: ENGINE KNOCK Flame Mode • • • Non-Flame Mode (autoignition) • In internal combustion engines, compressed gasoline-air mixtures have a tendency to ignite prematurely rather than burning smoothly This creates engine knock, a characteristic rattling or pinging sound in one or more cylinders. Octane number of gasoline is a measure of its resistance to knock (or its ability to wait for a spark to initiate a flame). Octane number is determined by comparing the characteristics of a gasoline to isooctane (2,2,4trimethylpentane) and heptane. – Isooctane is assigned an octane number of 100. It is a highly branched compound that burns smoothly, with little knock. – Heptane is given an octane rating of zero. It is an unbranched compound and knocks badly. 12 5. DIFFUSION FLAMES • • • Reactants are initially separated, and reaction occurs only at interface between fuel and oxidizer (mixing and reaction taking place) Diffusion applies strictly to molecular diffusion of chemical species In turbulent diffusion flames, turbulent convection mixes fuel and air macroscopically, then molecular mixing completes process so that chemical reactions can take place Orange Blue Full range of f throughout reaction zone 13 DIFFUSION FLAME: EARTH vs. SPACE 14 4+5: LOOK AGAIN AT BUNSEN BURNER Secondary diffusion flame Results when CO and H products from rich inner flame encounter ambient air Fuel-rich pre-mixed inner flame • • • What determines shape of flame? (ANS: velocity profile and heat loss to tube wall) Under what conditions will flame remain stationary? (ANS: flame speed must equal speed of normal component of unburned gas at each location) Most practical devices (Diesel-engine combustion) has premixed and diffusion burning 15 PROPULSION SYSTEMS Gas Turbine Engine for Propulsion X-37B Orbital Test Vehicle Gas Turbine Engine for Power Generation 16 5: DIFFUSION FLAMES 17 7. DETONATION • Pure Explosion vs. Detonation (not same) – Explosion requires rapid energy release • An explosion does not necessarily require passage of a combustion wave through exploding medium – Both deflagrations and detonations require rapid energy release and presence of a waveform • To have either a deflagration or a detonation, an explosive gas mixture must exist • Recall: • Deflagration: a subsonic wave sustained by a chemical reaction • Detonation: a supersonic wave sustained by a chemical reaction 18 7. PULSE DETONATION ENGINES 19 PULSE DETONATION WAVE ENGINES • Liquid methane or liquid hydrogen is ejected onto fuselage • Fuel mist is ignited, possibly by surface heating • The PDWE works by creating a liquid hydrogen detonation inside a specially designed chamber when aircraft is traveling beyond speed of sound – When traveling at such speeds, a thrust wall is created in front of the aircraft – When detonation takes place, airplane's thrust wall is pushed forward – This process is continually repeated to propel aircraft "...use a shock wave created in a detonation - an explosion that propagates supersonically- to compress a fuel-oxidizer mixture prior to combustion, similar to supersonic inlets that make use of external and internal shock wave for pressurization." 20 8. EMISSIONS AND POLLUTANTS • Major pollutants produced by combustion are: – Unburned and partially burned hydrocarbons, CnHm – Nitrogen oxides (NOx, NO and NO2) – Carbon monoxide (CO) – Sulfur oxides (SOx, SO2 and SO3) • Subjected to legislated controls (smog, acid rain, global warming, ozone depletion, health hazards, etc.) 21 EXAMPLES OF EMISSIONS Organic Compounds and Unburned hydrocarbons CO emissions Note that Clean Air Act of 1970 can be clearly seen in figures 22 8. EMISSIONS AND POLLUTANTS • Aircraft deposit combustion products at high altitudes, into upper troposphere and lower stratosphere (25,000 to 50,000 feet) • Combustion products deposited there have long residence times, enhancing impact • NOx suspected to contribute to toxic ozone production – Goal: NOx emission level to no-ozone-impact levels during cruise 23 DOES COMBUSTION SCALE? • What are limiting effects on combustion system size? • Can you burn at any scale? • Do any non-dimensional numbers exist to predict combustion scaling? 24 DETAILED EXAMPLE: DIFFUSION FLAMES • Reactants are initially separated, and reaction occurs only at interface between fuel and oxidizer (mixing and reaction taking place) • • • • • • PW4000 Fan Engine Cutaway Characteristics Fan tip diameter: 94 inches; Length: 132.7 inches Take-off thrust: 52,000 62,000 pounds; Bypass ratio: 4.8 to 5.0 Overall pressure ratio: 27.5 32.3; Fan pressure ratio: 1.65 1.80; Planes powered: Boeing 747400, MD-11, Airbus A300610, etc. 25 Turbine Compressor MAJOR COMBUSTOR COMPONENTS 26 MAJOR COMBUSTOR COMPONENTS Turbine Compressor Fuel • Key Questions: – Why is combustor configured this way? – What sets overall length, volume and geometry of device? 27 COMBUSTOR EXAMPLE (F101) Henderson and Blazowski Compressor Turbine NGV Fuel 28 VORBIX COMBUSTOR (P&W) • Example of vortex enhanced combustion • Why is turbulence helpful? 29 COMBUSTOR REQUIREMENTS • • • • • • • • • • • Complete combustion (hb → 1) Low pressure loss (pb → 1) Reliable and stable ignition Wide stability limits – Flame stays lit over wide range of p, u, F/A ratio) Freedom from combustion instabilities Tailored temperature distribution into turbine with no hot spots Low emissions – Smoke (soot), unburnt hydrocarbons, NOx, SOx, CO Effective cooling of surfaces Low stressed structures, durability Small size and weight Design for minimum cost and maintenance • Future – multiple fuel capability (?) 30 CHEMISTRY REVIEW • • General hydrocarbon, CnHm (Jet fuel H/C~2) Complete oxidation, hydrocarbon goes to CO2 and water m m Cn H m n O2 nCO2 H 2O 4 2 • • • For air-breathing applications, hydrocarbon is burned in air Air modeled as 20.9 % O2 and 79.1 % N2 (neglect trace species) Complete combustion for hydrocarbons means all C → CO2 and all H → H2O m m m Cn H m n O2 3.78 N 2 nCO2 H 2O 3.78 n N 2 4 2 4 Stoichiometric Molar fuel/air ratio ys • 1 m 4.78 n 4 Stoichiometric Mass fuel/air ratio ys 12n m m n 32 3.7828 Stoichiometric = exactly correct ratio for complete combustion 4 31 COMMENTS ON CHALLENGES • Based on material limits of turbine (Tt4), combustors must operate below stoichiometric values – For most relevant hydrocarbon fuels, ys ~ 0.06 (based on mass) • Comparison of actual fuel-to-air and stoichiometric ratio is called equivalence ratio – Equivalence ratio = f = y/ystoich – For most modern aircraft f ~ 0.3 • Summary – If f = 1: Stoichiometric – If f > 1: Fuel Rich – If f < 1: Fuel Lean 32 WHY IS THIS RELEVANT? • Most mixtures will NOT burn so far away from stoichiometric – Often called Flammability Limit – Highly pressure dependent • Increased pressure, increased flammability limit – Requirements for combustion, roughly f > 0.8 • Gas turbine can NOT operate at (or even near) stoichiometric levels – Temperatures (adiabatic flame temperatures) associated with stoichiometric combustion are way too hot for turbine – Fixed Tt4 implies roughly f < 0.5 • What do we do? – Burn (keep combustion going) near f=1 with some of ingested air – Then mix very hot gases with remaining air to lower temperature for turbine 33 Compressor Air Turbine SOLUTION: BURNING REGIONS Primary Zone f~0.3 f ~ 1.0 T>2000 K 34 COMBUSTOR ZONES: MORE DETAILS 1. Primary Zone – Anchors Flame – Provides sufficient time, mixing, temperature for “complete” oxidation of fuel – Equivalence ratio near f=1 2. Intermediate (Secondary Zone) – Low altitude operation (higher pressures in combustor) • Recover dissociation losses (primarily CO → CO2) and Soot Oxidation • Complete burning of anything left over from primary due to poor mixing – High altitude operation (lower pressures in combustor) • Low pressure implies slower rate of reaction in primary zone • Serves basically as an extension of primary zone (increased tres) – L/D ~ 0.7 3. Dilution Zone (critical to durability of turbine) – Mix in air to lower temperature to acceptable value for turbine – Tailor temperature profile (low at root and tip, high in middle) – Uses about 20-40% of total ingested core mass flow – L/D ~ 1.5-1.8 35 COMBUSTOR DESIGN • Combustion efficiency, hb = Actual Enthalpy Rise / Ideal Enthalpy Rise – h=heat of reaction (sometimes designated as QR) = 43,400 KJ/Kg cP m a m f Tt 4 m aTt 3 hb m f h • General Observations: 1. hb ↓ as p ↓ and T ↓ (because of dependency of reaction rate) 2. hb ↓ as Mach number ↑ (decrease in residence time) 3. hb ↓ as fuel/air ratio ↓ • Assuming that fuel-to-air ratio is small: cP Tt 4 Tt 3 f hbQR 36 COMBUSTOR LOCATION Commercial PW4000 Combustor Military F119-100 • Why is AB so much longer than primary combustor? Afterburner – Pressure is so low in AB that they need to be very long (and heavy) – Reaction rate ~ pn (n~2 for mixed gas collision rate) 37 EQUATION OF STATE • • • An equation of state provides a relationship among P, T and V (or r) of a substance Ideal gas behavior (neglect intermolecular forces and volume of molecules themselves): – P=rRT – Pv=RT – PV=mRT – R=Runiversal/MW, Runiversal=8314 J/kmol K Assumption is appropriate for nearly all systems we will consider in MAE 5310 since high temperatures associated with combustion generally result in sufficiently low densities for ideal gas behavior to be a reasonable approximation Aside: • Real gas laws try to predict true behavior of a gas better than ideal gas law by putting in terms to describe attractions and repulsions between molecules – These laws have been determined empirically or based on a conceptual model of molecular interactions or from statistical mechanics – Examples: van der Waals and Redlich-Kwong equations 38 1st LAW OF THERMODYNAMICS Fixed Mass • In Words: Heat added to system in going from state 1 to state 2 (Q) minus work done by system in going from state 1 to state 2 (W) equals change in total system energy (E) in going from state 1 to state 2 Q12 W12 E12 Units of Energy (J) 1 2 E m u V gz 2 q12 w12 e12 e2 e1 Control Volume • In Words: Rate of heat transferred across control surface from the surroundings to control volume minus rate of all work done by control volume (including shaft work, but excluding flow work) equals rate of energy flowing out of control volume minus rate of energy flowing into control volume plus net rate of work associated with pressure forces where fluid crosses the control surface, called flow work Q W m e m e m P v P v CV CV o i o o Unit mass basis (J/kg) dE Q12 W12 Units of Power (W) dt de Unit mass basis q w Representing an instant in time dt i i 1 Q CV WCV m ho hi Vo2 Vi 2 g zo zi 2 1 qcv wcv ho hi Vo2 Vi 2 g zo zi 2 Assumptions: • CV is fixed relative to coordinate system • Properties of fluid at each point within CV, or on the CS, do not vary with time • Fluid properties are uniform over inlet and outlet flow areas • Only one inlet and outlet stream – keep this form simple, but can be easily relaxed to allow for multiple inlet/outlet streams 39 ADDED, BUT HIGHLY IMPORTANT, COMPLEXITY Example: • Enthalpy often approximated as h(T)=CpT • In combustion chemistry, enthalpy must take into account variable specific heats, h(T)=Cp(T)T • If Cp(T) can be fit with quadratic, solution for flame temperature for certain classes of problems f < 1 and T < 1,250 K leads to closed form solutions • For higher order fits or f > 1 and/or T > 1,250 K, iterative closure schemes are required for solution of flame temperature 40 • • IDEAL-GAS MIXTURES: SOME USEFUL FORMULAS Ni Ni Mole fraction of species i, ci ci Sum of all constituent mole fraction is unity N1 N 2 ...N i ... N total c i 1 i • • Mass fraction of species i, Yi Sum of all constituent mass fractions is unity Yi Y i mi m i m1 m2 ...mi ... mtotal 1 i • • c i MWi Converting mole fraction to mass fraction – MW = molecular weight Yi Converting mass fraction to mole fraction Yi MWmixture ci MWi MWmixture 41 HOW TO CALCULATE STOICHIOMETRIC FUEL/AIR RATIO • • General hydrocarbon, CnHm Complete oxidation, hydrocarbon goes to CO2 and water m m Cn H m n O2 nCO2 H 2O 4 2 • • For air-breathing applications, hydrocarbon is burned in air Air modeled as 20.9 % O2 and 79.1 % N2 (neglect trace species) m m m Cn H m n O2 3.78 N 2 nCO2 H 2O 3.78 n N 2 4 2 4 • Stoichiometric Molar fuel/air ratio ys 1 m 4.78 n 4 • Stoichiometric Mass fuel/air ratio ys 12n m m n 32 3.78 * 28 4 42 ABSOLUTE (STANDARD) ENTHALPY, hi, AND ENTHALPY OF FORMATION, hºf,i • • For chemically reacting systems concept of absolute enthalpy is very valuable Define: – Absolute enthalpy = enthalpy that takes into account energy associated with chemical bonds (or lack of bonds) + enthalpy associated only with T – Absolute enthalpy, h = enthalpy of formation, hf + sensible enthalpy change, hs – In symbolic form: hi T h • f ,i T h T ref s ,i ref – In words first equation says: • Absolute enthalpy at T is equal to sum of enthalpy of formation at standard reference state and sensible enthalpy change in going from Tref to T To define enthalpy, you need a reference state at which enthalpy is zero (this state is arbitrary as long as it is same for all species). – Most common is to take standard state as Tref=298.15 K and Pº=1 atm (Appendix A) – Convention is that enthalpies of formation for elements in their naturally occurring state at reference T and P are zero. • Example, at Tref=25 ºC and Pº=1 atm, oxygen exists as a diatomic molecule, so: hf ,O2 Tref , P hf ,O2 0 • Note: Some text books use H for enthalpy per mol (Glassman), some books use h for enthalpy per mol, some use h for enthalpy per mol. Use any symbol you like, just know what equations require. 43 GRAPHICAL EXAMPLE Graphical interpretation of absolutely enthalpy, heat of formation and sensible enthalpy • See Figure 2.6 and Appendix A.11 and A.12 • Physical interpretation of enthalpy of formation: net change in enthalpy associated with breaking the chemical bonds of the standard state elements and forming news bonds to create the compound of interest 44 COMMENTS ON TABLE 1: POTENTIAL ENERGY CHART Consider two reactions: More Endothermic ½O2 → O • Heat of formation (gas): 249.17 kJ/mol • Reaction is endothermic More Exothermic H2+½O2 → H2O • Heat of formation (gas): -241.83 kJ/mol • Reaction is exothermic H2O → H2+½O2 • Reaction 1 going backwards • Reaction is endothermic 45 ENTHALPY OF COMBUSTION AND HEATING VALUES • The heat of combustion, also known as heating value or heat of reaction, is numerically equal to enthalpy of reaction, but with opposite sign – Heat of combustion (or heat of reaction) = - enthalpy of combustion (or = - enthalpy of reaction) • If heat of combustion (or heat of reaction) is positive → Exothermic • If heat of combustion (or heat of reaction) is negative → Endothermic • If enthalpy of combustion (or enthalpy of reaction) is positive → Endothermic • If enthalpy of combustion (or enthalpy of reaction) is negative → Exothermic • The upper or higher heating value, HHV, is the heat of combustion calculated assuming that all of water in products has condensed to liquid. – This scenario liberates most amount of energy, hence called ‘upper’ • The lower heat value, LHV, corresponds to case where none of water is assumed to condense 46 LATENT HEAT OF VAPORIZATION, hfg • In many combustion systems a liquid ↔ vapor phase change may occur – Example 1: A liquid fuel droplet must first vaporize before it can burn – Example 2: If cooled sufficiently, water vapor can condense from combustion products • Latent Heat of Vaporization (also called enthalpy of valorization), hfg: Heat required in a constant P process to completely vaporize a unit mass of liquid at a given T – hfg(T,P) ≡ hvapor(T,P)-hliquid(T,P) – T and P correspond to saturation conditions T, v diagram for heat process of water at P=1 atm • Latent heat of vaporization is frequently used with Clausius-Clapeyron equation to estimate Psat variation with T dPsat h fg dTsat 2 Psat R Tsat – Assumptions: • Specific volume of liquid phase is negligible compared to vapor • Vapor behaves as an ideal gas – If hfg is constant integrate to find Psat,2 if Tsat,1 Tsat,2, and Psat,1 are known – We will do this for droplet evaporation and combustion, e.x. D2 law 47 SELECTED PROPERTIES OF HYDROCARBON FUELS 48 ADIABATIC FLAME TEMPERATURE • For an adiabatic combustion process, with no change in KE or PE, temperature of products is called Adiabatic Flame Temperature – Maximum temperature that can be achieved for given concentrations of reactants – Incomplete combustion or heat transfer from reactants act to lower temperature • Adiabatic flame temperature is generally a good estimate of actual temperature achieved in a flame, since chemical time scales are often shorter than those associated with transfer of heat and work • Most common is constant-pressure adiabatic flame temperature H reac Ti , P H prod Tad , P hreac Ti , P hprod Tad , P • Conceptually simple, but in practice difficult to evaluate because requires detailed knowledge of product composition, which is function of temperature 49 1st LAW FOR COMBUSTION PROBLEMS (GLASSMAN) • Most general form (rarely used, but know what each term means) Sensible enthalpy change (kJ/mol) relative to some reference T H n H i i , prod T2 Sensible enthalpy change from T=298 to some reference Term is zero if reference T=298 H H H 0 T0 H f T 0 n j H T0 H 0 H T0 H 0 H f i , react Sensible enthalpy change relative to some reference T Term is zero if reactants enter at some reference T • 0 Enthalpy of formation of products at T=298 K T0 Q i p j Sensible enthalpy change from T=298 to some reference Term is zero if reference T=298 Enthalpy of formation of reactants at T=298 K Note on sign of Q is negative. This is consistent with the 1 st Law, but you must recall that Qp the is heat evolved, or the heat given off by the system, or the heat of combustion or heat of reaction. 50 1st LAW FOR COMBUSTION PROBLEMS (GLASSMAN) • Much more common, and what we will use in MAE 5310 Sensible enthalpy change relative to T=298 K H ni H T2 H T0 H f i , prod Enthalpy of formation of products at T=298 K n j H T1 H T0 H f i , react Sensible enthalpy change relative to T=298 K This term is zero if reactants enter the system at T=298 K T0 T0 Q i p j Enthalpy of formation of products at T=298 K 51 ADIABATIC FLAME TEMPERATURE (GLASSMAN) • • • For an adiabatic combustion process, with no change in KE or PE, temperature of products is called Adiabatic Flame Temperature, Tad Maximum temperature that can be achieved for given concentrations of reactants – Incomplete combustion or heat transfer from the reactants act to lower the temperature The adiabatic flame temperature is generally a good estimate of the actual temperature achieved in a flame, since the chemical time scales are often shorter than those associated with transfer of heat and work i , prod ni H Tad H T0 H f T0 n H j i i , react T1 H T0 H f T0 j 52 EXAMPLE: FUEL-LEAN OCTANE-AIR COMBUSTION • Calculate Tad of normal octane (liquid) burning in air at f= 0.5 – Assume no dissociation of stable products formed – All reactants are at 298 K and system operates at a pressure of 1 atm – Compare results with figure 53 THERMOCHEMICAL DATA (GLASSMAN): CO2, H2O 54 THERMOCHEMICAL DATA (GLASSMAN): N2, O2 55 COMMENT ON NOTATION Turns Notation : H : Enthalpy [J] h : Enthalpy [J/kg] h : Enthalpy [J/kmol] N : Number of Moles H prod N h i i N h H react prod i i react Glassman Notation : H : Enthalpy [J] or [kJ/mol] h : Enthalpy [kJ/g] n H i i , prod Ta d H T0 H f T0 n H j i i , react T1 H T0 H f T0 j 56 CHEMICAL EQUILIBRIUM • So far we have calculated adiabatic flame temperature assuming complete combustion – All fuel is completely oxidized to form CO2, H2O and excess O2 and N2 are carried through unaffected • • Assumption reasonable for T < 1250 K, but most combustion systems operate at higher T Species that are normally stable at ambient conditions dissociate 1 CO2 CO O2 2 1 H 2O H 2 O2 2 • • Concentration is determined by a balance between oxidation and formation Balance is a function of T, P and concentration • Note: The chemical equilibrium relations we will use still only approximate the species concentrations in a combustion process. That is, they rest on the assumption that the conditions are constant for a sufficiently long time for all the reactions to reach equilibrium 57 ADDITIONAL PRODUCT FORMATION • NO Dissociation: Complete Combustion – Equivalence ratio less than or equal unity, f ≤ 1 – The products formed are: CO2, H2O, O2, and N2 – Equivalence ratio greater than unity, f > 1 – The products formed are: CO2, CO, H2O, H2, and N2 • WITH Dissociation – Products formed include: CO2, CO H2O, H2, H, OH, O2, O, NO, N2, and N – Concentration is dependent on T, P and f 58 CHEMICAL EQUILIBRIUM FOR A FIXED-MASS SYSTEM 1 CO O2 CO2 2 1 a CO O2 1 a CO2 aCO O2 2 2 • • • If final temperature of combustion reaction is high enough, CO2 will dissociate Can calculate adiabatic flame temperature as function of a (a = fraction of CO2 dissociated) Must consider second law: dS ≥ 0 Smix T f , P ni si T f , Pi • • • Composition of system will shift toward point of maximum entropy when approaching from either side, since dS is positive Once maximum entropy is reached no further changes since would violate second law (dS)U,V,m = 0 59 PROPANE-AIR COMBUSTION AT 1 ATM Adopted From: Turns, S.R., Introduction to Combustion 60 • • To arrive at equilibrium relations, employ 2nd Law of Thermodynamics State 2nd Law in terms of Gibbs Free Energy, G=H-TS • For a closed system at constant T and P, the Gibbs free energy is minimum at thermodynamic equilibrium dS Q dSirrev T Q dH VdP TdS dH VdP TdSirrev G S T P ,ni G V P T ,ni TdSirrev i dG SdT VdP TdSirrev G dni ni T , P Basic Thermodynamic Relations 2nd LAW OF THERMODYNAMICS: GIBBS FREE ENERGY G i n dni 0 i T ,P Criteria for Equilibrium 61 MORE USEFUL FORMS • • Gi=Hi-TSi Separate Gi into a pressure dependent and term and pressure independent term – Recall that Cpi is not a function of pressure Gi Gi T RT ln Pi T Cpi Gi T Cpi dT h f T0 T Si T0 dT T T0 T0 T PCc PDd G RT ln a b PA PB aA bB cC dD PCc PDd K P K P T a b PA PB Another useful form K P T c i P i G RT ln K P • Equation 40 i , gas The more negative Gº is, the larger Kp is and the more spontaneous the reaction is 62 COMMENTS ON KP 1. The Kp of a reaction depends on temperature only – Independent of pressure of the equilibrium mixture – Not affected by presence of inert gases 2. The Kp of the reverse reaction is 1/ Kp 3. The larger the Kp, the more complete the reaction – If Kp > 1,000 (or ln Kp > 7) reaction assumed complete – If Kp < 0.001 (or ln Kp < -7) reaction assumed not to occur 4. Mixture pressure affects the equilibrium composition (but not Kp) 5. Presence of inert gases affects the equilibrium composition 6. When stoichiometric coefficients are doubled, the value of Kp is squared 7. Free electronic in the equilbrium composition can be treated as an ideal gas 8. Equilibrium calculations provide information on the equilibrium composition of a reaction, not on the reaction rate. 63 ADIABATIC COMBUSTION EQUILIBRIUM • Previously we have considered: – Known Stoichiometry + 1st Law (Energy Balance) → Adiabatic Flame Temperature • Problems 1-4 – Known P and T + 2nd Law (Equilibrium Relations) → Stoichiometry • Problems 5-9 • Now we can combine these: – 1st Law (Energy Balance) + 2nd Law (Equilibrium Relations) → Adiabatic Flame Temperature + Stoichiometry • Problems 10-14 • Solution Scheme 1. Guess a T=Tguess 2. Do equilibrium calculation to solve for species concentrations at Tguess 3. Plug into 1st Law F Tguess ni H Tad H T0 H f T n j H T1 H T0 H f i , prod • 1. 0 i i , react T0 0 j We want F(Tguess)=0 • If F(Tguess) > 0, then initial guess was too high • If F(Tguess) < 0, then initial guess was too low Increment Tguess 64 EXAMPLE: MONOPROPELLANT ROCKET PROPULSION • • • • Monopropellant rockets are simple propulsion systems that rely on chemicals which, when energized, decompose Decomposition creates both the fuel and an oxidizer (which allows the fuel to burn), which then react with each other Because they only use a single propellant, monopropellant rockets are quite simple and reliable, but not very efficient Mainly used to make small adjustments such as attitude control – Typical Specific Impulse: 100-300 sec – Typical Thrust: 0.1-100 N Monopropellant hydrazine (N2H4, see Problem 12) thrusters that were used for trajectory correction maneuvers (TCMs) during interplanetary cruise, thrust vector control (TVC) during VOI, orbit trim maneuvers during the mapping mission, and attitude control when the action wheels are being desaturated. The rocket motors are clustered in modules located on the end of outrigger booms in order to increase their moment arm and thus decrease attitude control propellant requirements. Twelve 0.9-N (Newton) and four 22-N rocket motors are used for attitude control, with thrust being provided by eight 445-N rocket motors or by the 0.9-N motors for small TCMs. 65 EXAMPLE: MONOPROPELLANT ROCKET PROPULSION • • • • Rocket propellant chemists have proposed a new, high-energy liquid oxidizer, penta-oxygen, O5, which is also a monopropellant. Calculate the monopropellant decomposition temperature at a chamber pressure of 10 atm. If it is assumed the only products are O atoms and O2 molecules. Supplemental Information: – Heat of formation of new oxidizer is estimated to be very high: 1,025 kJ/mole – O5 enters system at 298 K – Amount of O2 and O should be calculated for one mole of O5 decomposing Solution Technique – Solution is iterative – In order to calculate the final temperature of the mixture, one needs to the composition of the mixture at equilibrium – but – the composition of the mixture can only be found if the final temperature is known. – Strategy: • Guess final temperature and calculate mixture composition using equilibrium concept • Once composition is known at guessed temperature, adiabatic flame temperature is calculated and checked against guessed value • Repeat process until guessed and calculated temperatures are same – Answer lies somewhere between 4,000 and 5,000 K 66 PRACTICAL APPLICATION: RECUPERATION • A recuperator is a heat exchanger in which energy from a steady flow of hot combustion products, called flue gases, is transferred to the air supplied to the combustion process 67 SOME COMMON TYPES OF RECUPERATORS http://www.hardtech.es/hgg_tt_hrt.0.html Tubes cage radiation recuperator Tubes cage radiation recuperator working at 1,200ºC Double shell radiation recuperator Installation consisting of a tubes cage recuperator and a double shell one, series-connected 68 EXAMPLE: RECUPERATION (TURNS) 1. 2. A recuperator, as shown in figure, is employed in a natural-gas-fired heating-treating furnace. The furnace operates at atmospheric pressure with an equivalence ratio of 0.9. The fuel gas enters the burner at 298 K, while the air is pre-heated. Determine the effect of air preheat on the adiabatic flame temperature of the flame zone for a range of inlet air temperatures from 298 K to 1,000 K. What fuel savings result from preheating the air from 298 K to 600 K? Assume that temperature of flue gases at furnace exit, prior to entering recuperator, is 1700 K, both with and without preheat. Radiant-tube burner with coupled Recuperator for indirect firing. Note that All flue gases pass through the recuperator Source: Turns, An Introduction to Combustion 69 NASA CEA PRACTICE PROBLEM Consider combustion of a methane-air mixture at 10 atm (both fuel and air are at 10 atm). 1. Plot mole fractions, ci, for the species CO2, CO, H2O, H2, OH, O2, N2, NO vs. temperature for f=1 for a temperature range from 1000 to 2500 K. 2. Calculate Tflame and mole fractions as a function of f for adiabatic combustion. Plot these results vs. f and discuss at what value the peak flame temperature occurs. Comment on this value in light of the discussion found in Chapter 1, Part 2 of Glassman. 3. Compare Tflame from part (2) to what would be obtained assuming complete oxidation (burning in only oxygen) and what would be obtained assuming complete combustion (burning in air). 70