9-1

Business in a

Changing World

Chapter 9

Production and Operations

Management

2

McGraw-Hill/Irwin

Copyright © 2009 by the McGraw-Hill Companies, Inc. All rights reserved.

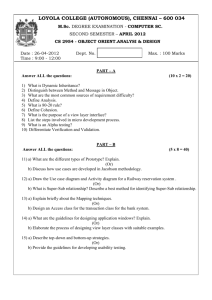

9-3

Goya Foods: Quality

Operations and Products

Goya Foods offers a wide range of products. As

their product lines have expanded, management

of operations has become a major priority.

9-4

Operations Management

Importance of Production & Operations Management

The planning and designing of the processes

that transform resources into finished

products; managing the transformation

process; ensuring high quality of finished

goods.

9-5

Operations Management

Operations Management (OM)

Development and administration of the activities

involved in transforming resources into goods

and services.

9-6

Operations Management

Operations Management (OM)

•Historically called production or manufacturing

•Change to operations = focus on goods & services

•Emphasis on viewing the operations function as a whole

9-7

Production & Operations Management

Manufacturing – activities and processes used in

making tangible products (production)

Production – activities and processes used in

making tangible products (manufacturing)

Operations – the activities and processes used in

making both tangible and intangible products

9-8

Production & Operations Management

Transformation Process of operations management

9-9

Transformation Process

Inputs –

•Labor

•Money

•Materials

•Energy

Outputs

•Goods

•Services

•ideas

9-10

Production & Operations Management

Inputs, outputs, and transformation processes

Manufacturing Oak Furniture

9-11

Operations Management

OM in Service Businesses

Service Businesses –

•Airlines

•Colleges

•Nonprofit organizations

9-12

Operations Management

OM in Service Businesses

Service Businesses – 70% of all employment in

the United States; fastest growth of jobs

9-13

Operations Management

OM in Service Businesses

Service Businesses – actions that are directed

toward consumers who use them

9-14

Operations Management

OM in Service Businesses

Ideal Service Business - Customer contact

•High-tech

•High-touch

9-15

Operations Management

OM in Service Businesses

Service Business Output

• Intangible

• Perishable

• Difficult to gauge demand

9-16

Operations Management

Differences in Nature & Consumption of Output

(Manufacturing vs. Service Providers)

•Nature and consumption of output

•Uniformity of inputs

•Uniformity of outputs

•Labor required

•Measurement of productivity

9-17

Planning & Designing Operations Systems

Planning the Product

Determine –

•What consumers want

•Design product to satisfy the want

•Marketing research

9-18

Planning & Designing Operations Systems

Planning the Product

Determine –

•Types and quantities of raw materials

•Skills & quantity of labor

•Processes for transformation to outputs

9-19

Designing the Operations Processes

Standardization – the making of identical

interchangeable components or products. Faster,

reduces production costs

•Televisions

•Ballpoint pens

•Tortilla chips

9-20

Designing the Operations Processes

Modular Design – creation of an item in selfcontained units that can be combined or

interchanged to create different products

•Personal computers -- CPU’s, motherboards, monitors

9-21

Designing the Operations Processes

Customization – making products to meet a

particular customer’s needs or wants

•Repair services

•Photocopy services

•Custom artwork

•Bridges

•Ships

•Computer software

9-22

Designing the Operations Processes

Mass Customization – making products to meet

needs or wants of a large number of individual

customers.

•Customer selects

•Model, size, color, style, design

•Dell Computer

•Fitness program

•Travel packages

9-23

Planning Capacity

Capacity – maximum load that an organizational

unit can carry or operate

•Hershey’s production capacity

•33 million Hershey’s kisses per day

•12 billion per year

9-24

Planning Facilities

Facility location

Facility layout

Technology

9-25

Planning Facilities

Facility layout

• Fixed-Position Layout

• Project Organization

• Process Layout (intermittent

organizations)

• Product Layout (continuous

manufacturing organization)

9-26

Planning Facilities

Fixed-Position Layout--Project organization

All resources needed for a product are brought to a

central location.

Process Layout--Intermittent organization

Layout is organized into departments that group related

processes.

Product Layout--Continuous manufacturing

organization

Production is broken down into relatively simple tasks

assigned to workers positioned along a line.

9-27

Planning Facilities -- Technology

Computer-assisted design (CAD) – design of components,

products, and processes utilizing computers instead of paper

& pencil

Computer-assisted manufacturing (CAM) – manufacturing

that employs specialized computer systems to actually guide

and control the transformation processes.

9-28

Planning Facilities -- Technology

Flexible manufacturing – the direction of machinery by

computers to adapt to different versions of similar operations

Computer-integrated manufacturing (CIM) – a complete

system that designs products, manages machines and

materials, and controls the operations function.

9-29

Facilities Planning

Robotics Industries Association –

Estimate – 160,000 robots at work in U.S.

factories – Japan #1 employer of robotics

9-30

Green Manufacturing

• It pays to go green

– The affluent use green products as status symbols

• Smart Car’s US sales are soaring, as it has the

highest mgp of any gas-powered car on the

market

– 95% of Smart Car buyers opt for deluxe versions over

the base model

9-31

Managing the Supply Chain

Supply chain management

Connecting and integrating all parties or

members of the distribution system in order to

satisfy customers.

9-32

Managing the Supply Chain

Purchasing

Procurement – buying of all materials

needed by the organization.

•Desired quality

•Correct quantities

•Lowest cost

9-33

Managing the Supply Chain

Managing Inventory

Inventory – all raw materials, components,

completed or partially completed products,

and pieces of equipment that a firm uses

9-34

Managing the Supply Chain

Managing Inventory

Inventory control – process of determining

how many supplies and goods are needed and

keeping track of quantities on hand, where

each item is, and who is responsible for it.

9-35

Managing the Supply Chain

EOQ model

Economic order quantity model – a model

that identifies the optimum number of items

to order to minimize the costs for managing

them (ordering storing, and using).

9-36

Managing the Supply Chain

JIT

Just-in-Time inventory management – eliminates

waste by using smaller quantities arriving “just in

time” for use in the transformation process.

9-37

Managing the Supply Chain

MRP

Material-requirements planning – planning

system that schedules the precise quantity of

materials needed to make the product.

9-38

Managing the Supply Chain

Outsourcing

Outsource aspects of operations to companies

that provide products more efficiently, at lower

cost, greater customer satisfaction.

9-39

Managing the Supply Chain

Routing – sequence of operations through

which the product must pass

Scheduling – the assignment of required tasks

to departments or specific machines, workers,

or teams.

9-40

Managing Quality

Quality – critical element of operations

management. Degree to which a good or

service meets the demands and requirements

of customers.

9-41

Managing Quality

Hypothetical PERT Diagram for a McDonald’s Big Mac

9-42

Managing Quality

Quality complaints from Air Travelers -- 2007

9-43

Managing Quality

Malcolm Baldrige National Quality Award

Criteria -•

•

•

•

•

•

•

Leadership

Information and analysis

Strategic planning

Human resource development

Process management

Business results

Customer focus & satisfaction

9-44

Managing Quality

Quality Control – processes an organization uses

to maintain its established quality standards.

Total Quality Management (TQM) – philosophy

that uniform commitment to quality will promote

a culture that meets customers’ perceptions of

quality.

9-45

Managing Quality

Statistical process control – system to collect and

analyze information about production processed

to pinpoint quality problems in the system.

ISO 9000 – International Organization for

Standardization (ISO) system of quality

management standards designed to ensure the

customer’s quality standards are met.

9-46

Managing Quality

Inspection – reveals whether a product meets

quality standards.

Sampling – how many items should be inspected.

Depends on potential costs of product flaws in

terms of human lives and safety.

9-47

Communications in Organizations

Informal Communication – separate from

management’s formal, official communication

channels.

•Grapevine

9-48