Management Accounting and Control Systems for Strategic Purposes

advertisement

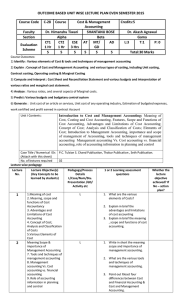

Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Chapter 9 Management Accounting and Control Systems for Strategic Purposes: Assessing Performance over the Entire Value Chain Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Chapter Objectives: To be able to: 1. 2. 3. 4. 5. 6. 7. Apply the concept of control. Identify the characteristics of well-designed management accounting and control systems (MACS). Describe the total-life-cycle costing approach to managing product costs over the value chain. Explain target costing. Explain Kaizen costing. Identify environmental costing issues. Apply the process of benchmarking the best practices of other organizations. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Chapter 9: Technical aspects of MACS design using benchmarking and best practice. Chapter 10: Behavioral characteristics of MACS design including human motivation. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Management accounting and control system: ”The larger entity of central performance measurement systems” Control: ”Refers to the set of procedures, tools, performance measures and systems that organizations use to guide and motivate all employees to achieve organizational objectives”. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes In control/out of control: A state of expressing whether an organization is on the path of achieving its strategic objectives. The process of keeping an organization in control: 1. 2. 3. 4. 5. Department of Accounting Planning Execution Monitoring Evaluation Correcting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Characteristics of a well-designed management accounting and control system (1) (2) (3) (4) Embedding the organizations ethical code of conduct into MACS design. Using a mix of short/ and long/term qualitative and quantitative performance measures. Empowering employees to be involved in decision making and MACS design. Developing an appropriate incentive system to reward performance. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Characteristics of a well-designed management accounting and control system Technical considerations - Relevance of information (1) Accurate. Inaccurate information is not relevant or useful for decision making because it is misleading. Designers have to develop a system that leads to the most accurate information possible. For instance, more accurate product costs can be obtained by using systems that trace costs more directly from support activities to products. (2) Timely. Accurate information that is late is also of little use for decision making. The MACS must be designed so that the results of performance measurement are fed back to the appropriate units in the most expedient way possible. (3) Consistent. Designers must structure the MACS to provide a consistent framework that can be applied globally across the units or divisions of an entity. (4) Flexible. MACS designers must allow employees to use the systems available information in a flexible manner so they can customize its for local decisions. Departmentapplication of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Characteristics of a well-designed management accounting and control system Technical considerations - Scope of the system The scope of the MACS system must be comprehensive and include all activities across the entire value chain of the organization. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Total-Life-Cycle Costing, page 1 of 3 Life-cycle concepts: • Research, development and engineering cycle (RD&E). A life-cycle concept that involves market research, product design and product development. • Manufacturing cycle. Those costs incurred inside the factory associated with transforming raw materials into a finished product. • Post-sale service and disposal cycle. The portion of the life cycle that begins once the first unit of a product is in the hands of the customer. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Total-Life-Cycle Costing, page 2 of 3 RD&E Cycle: Stages: Market Research, where emerging customer needs are assessed and ideas are generated for new products. Product Design, in which scientists and engineers develop the technical aspects of products. Product Development, in which the company creates features critical to customer satisfaction and designs prototypes, production processes, and any special tooling required. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Total-Life-Cycle Costing, page 2 of 3 Manufacturing cycle: Stages: Costs are incurred in the production of the product. At this stage there is not as much room for engineering flexibility to influence product costs and product design. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Total-Life-Cycle Costing, page 3 of 3 Post-sale and Disposal Cycle. Stages: (1) Rapid growth from the first time the product is shipped through the growth stage of its sales. (2) Transition from the peak of sales to the peak in the service cycle. (3) Maturity from the peak in the service cycle to the time of the last shipment made to a customer. Disposal occurs at the end of a product life and lasts until the customer retires the final unit of a product. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Target Costing, page 1 of 4 Definition: A method of cost planning used during the planning cycle to reduce manufacturing costs to targeted levels. Target costing versus traditional cost-reduction methods. Traditional profit calculation methods: Desired profit margin = expected selling price less estimated costs Cost-plus method = expected profit margin + expected product cost In neither of the methods any attempt to achieve a particular cost target is being performed. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Target Costing, page 2 of 4 Target costing: The difference between the target selling price and the target profit margin. Once the target cost has been set, the company must determine target cost for each component. The value engineering process: The process of examining each component of a product to determine whether its cost can be reduced while maintaining functionality and performance. Exhibits 9-4 Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Target Costing, page 3 of 4 Listing differences of target costing compared to traditional costing methods: 1. 2. 3. 4. 5. Marketing research under target costing is not a single event as it often is under the traditional approach. Much more time is spent as the product specification and design stage in order to minimize design changes during the manufacturing when they are far more expensive to implement. Target costing uses the total-life-cycle concept by making it a key goal to minimize the cost of ownership of a product over its useful life. Throughout the entire process, cross-functional teams made up of individuals representing the entire value chain-both inside and outside the organization-guide the process. Suppliers play a critical role in making target costing work. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Target Costing, page 4 of 4 Supply Chain Management A management system that develops cooperative, mutually beneficial, long-term relationships between buyers and sellers. Concerns about target costing: - Conflicts among stakeholders - Stress factors - Increasing development time - Costing and quality How is it used? Target costing is gaining momentum as a management method; however it is not only a method of cost control, but also a comprehensive approach to profit planning and cost management. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Kaizen Costing, page 1 of 2 Kaizen is the Japaneese term for making improvements to a process through small, incremental amounts rather than through large innovations. Definition: A costing system that focuses on reducing costs during the manufacturing stage of the total life cycle of a product. Focus: In traditional cost systems focus is to meet standard cost measurement by avoiding unfavorable variances. Under Kaizen cost the goal is to achieve cost reduction targets that are continually adjusted downward. The Kaizen system is in opposition to traditional costing based on worker input to improve performance. Traditional standard costing assumes that engineers and managers with their technical and administrative expertise can set standards. Exhibit 9-7 How to compute Kaizen Costs for Plants. Exhibit 9-6 Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Kaizen Costing, page 2 of 2 Concerns about Kaizen costing: - The system places enormous pressure on employees to reduce every conceivable cost. - Kaizen costing leads to incremental rather than radical process improvements. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Environmental Costing Definition: A costing system that computes the cost of the effects an organization has on the environment. Identify environmental impacts during a products life cycle and establish management accounting guidelines of how to assign these costs to the most appropriate products, distribution channels and customers. Department of Accounting Management Accounting Chapter 9 - Management Accounting and Control Systems for Strategic Purposes Benchmarking Definition: The process of studying and adapting the best practices of other organizations to improve the firms own performance and establish a point of reference by which other internal performance can be measured. Options when an organization interested in a new management accounting method should choose how to approach it: 1. Bring in outside consultants to implement a particular method. Effective but costly. 2. Organizational members develop their own systems internally with little or no assistance from outside consultants. Can turn out to be highly costly and time consuming, especially if the organization fails in its first attempts. 3. Using benchmarking requiring that organizational members first understand their current operations and approaches to conducting business and then look to the best practices of other organizations for guidance on improving. Stages of the Benchmarking Process: Exhibit 9-9 Department of Accounting