BUSINESS MANAGEMENT SAC 3 Unit 3: Corporate Management

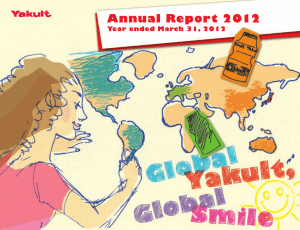

advertisement

BUSINESS MANAGEMENT SAC 3 Unit 3: Corporate Management Area of Study 3: The Operations Management Function Key Knowledge: the operations function and its relationship to business objectives and business strategy; characteristics of operations management within large-scale manufacturing and service organisations; key elements of an operations system (inputs, processes and outputs) in different types of large scale organisations; productivity and business competitiveness, their importance for and impact on the operations system; strategies adopted to optimise operations, including: – facilities design and layout – materials management – management of quality – extent of the use of technology; ethical and socially responsible management of an operations system. Key Skills: Accurately use relevant management terms; Analyse business information and data; Apply knowledge and concepts to practical and/or simulated situations. Analyse business information Analyse strategies that arise through practices within operations management Time Allowed: Reading Time – 5 minutes Writing time – 90 minutes Marks Allocated: 40 marks ∙ Students are permitted to bring into the examination room: pens, pencils, highlighters, erasers, sharpeners and rulers. ∙ Students are NOT permitted to bring into the examination room: blank sheets of paper and/or white out liquid/tape. ∙ No calculator is allowed in this examination. Materials Supplied ∙ Question and answer book is 6 pages ∙ Additional space is available at the end of the book if you need extra paper to complete an answer. Instructions ∙ Write your name in the space provided above on this page. ∙ All written responses must be in English. Students are NOT permitted to bring mobile phones and/or any other unauthorised electronic devices into the examination room. Students are also NOT permitted to leave the room during the SAC. The Production of Yakult (step by step) Yakult's purpose-built factory in Dandenong is a technologically advanced manufacturing facility. It incorporates some of the most up-to-date food-processing equipment available. Strict standards apply to producing Yakult, ensuring a drink yield that is close to 99 per cent (this means that 99 per cent of the raw ingredients end up in the bottle). There are no by-products and little waste. The Yakult factory in Australia is based in Dandenong, Victoria, which produces Yakult for the whole of Australia and New Zealand. Australia was the first English-speaking country chosen to launch Yakult due to its close proximity to Asia. Steps in the production process 1 Mixing of raw ingredients Skim milk powder, sugar and dextrose are mixed with filtered, sterilised water to make a sweet milky solution. 2 Sterilisation The sweet, milky solution is sterilised at a high temperature for a short time, destroying any bacteria that may be present. This process is called UHTST (Ultra Heat Treatment, Short Time). The solution is then transferred to a 6000-litre fermentation tank via a closed system of pipes and valves. 3 Fermentation tank Live Lactobacillus casei Shirota strain, cultured and tested in our laboratory, is added to the tank. The temperature of the tank is then reduced until the contents are at 37°C (body temperature). The solution is allowed to ferment in the tank for 6–9 days or until the numbers of Lactobacillus casei bacteria reach their ideal concentration. 4 Control Panel This machine is fully computerised and controls the flow of production. Different coloured lights indicate any areas that need attention. 5 Flavour tank Citrus flavour is added to the concentrate. 6 Storage tank The flavoured, concentrate is transferred to a 12 000-litre storage tank, containing a chilled syrup solution. The tank is chilled to around 2°C. 7 Water steriliser Yakult uses water that is de-mineralised (any dissolved chlorides and fluorides are removed) by a process called ‘reverse osmosis’. The water is then UV sterilised, after which it is stored in a 25 000-litre holding tank before being used in the production process. 8 Mixing tank Prior to bottling, the concentrate is diluted with filtered, sterile water at a ratio of 1:1. 9 Injection blowmoulding machine The plastic bottles are produced, on-site, from triple-grade food polystyrene. The injection blow-moulding machine has the capacity to produce 11 000 bottles per hour. 10 Bottle storage tank Extra bottles are made and stored in a large, sterile bottle storage tank that is capable of storing 750 000 bottles. 11 Selector Bottles drop down a large funnel from the bottle storage tank into a large circular selector that places the bottles in an upright position before being fed onto the filling line. 12 Printing station Bottles move along the conveyer belt to the printing station where the name ‘Yakult’ and the appropriate labelling information required by law are printed on the bottle in an instant-drying, red ink. 13 Filling, capping and sealing machine The filling machine has the capacity to fill 40 000 bottles of Yakult per hour. After the bottles are filled with Yakult, they are capped with a foil lid, printed with a use-by date, sealed and transferred along the conveyor belt to the packaging facility. 14 Shrink wrap and packaging machine It is here that the single bottles of Yakult are sorted into groups of five or 10 and shrinkwrapped in polyethylene film. Ten x five packs are grouped together and wrapped again in polyethylene film and then heat shrunk, forming a ‘slab’ of 50 Yakult bottles. 15 Finished product 16 Refrigeration room The slabs are transferred to a pallet, wrapped and stored at a temperature of 2–3°C while awaiting delivery to the stores. 17 Distribution Refrigerated trucks deliver Yakult to the warehouses of the major supermarket chains (e.g. Woolworths and Coles) for distribution to individual supermarkets. Yakult is also delivered directly to independent supermarkets, milk bars, gyms, health food stores, motels, hospitals and other outlets by Yakult sales consultants. 18 Hygiene Yakult is a fermented milk drink that contains a live bacterial culture. In order to maintain the high quality of Yakult, strict hygiene standards must be met in the production. 19 Yakult quality management system Yakult maintains a comprehensive quality management system that complies with the International Organization for Standardization (ISO 9001:2000). This ensures that its products and services meet the highest international food-manufacturing standards. To make sure that Yakult’s product is of the highest quality, samples are collected for laboratory analysis throughout the production process to confirm that the quality assurance measures and the quality control testing have been effective. Yakult testing involves more than 120 samples per production run, upon which a total of more than 120 tests are conducted. These determine Lactobacillus case numbers, check for potential contaminants, microbiological quality, composition, acidity, physical attributes and taste. In addition, each bottle is inspected for undesirable markings and incorrect printing. Quality assurance measures are in place to maintain standards for personnel and factory hygiene, equipment cleaning, processing methods and parameters, and product handling. Yakult's quality assurance utilises a system called ‘Hazard Analysis and Critical Control Points’ (HACCP). The principles of HACCP are internationally recognised as an excellent method for assuring stringently high standards. 20 Waste management Cleaning: Yakult adheres to a comprehensive hygiene and sanitation program, following a cleaning program that is predominantly governed by CIP (Cleaning in Place). Steam, an environmentally friendly cleaner, is used to sterilise the pipes and tanks. A single-phase chemical cleaner is used, reducing the numbers of chemicals introduced into the drains; chlorine-based chemicals are not used. Solid wastes: the amount of solid waste is relatively small and a number of measures are made to reduce waste. Recycling occurs where it is economically and environmentally viable. Paper products (skim milk powder bags, etc.) are recycled. The bottles are crushed and mixed with other resin to be made into a variety of plastic products, such as chairs and tables. Liquid wastes: any liquid waste goes into a holding tank in our water treatment facility. The acidity (pH) of the water is adjusted with acid or alkaline to meet Melbourne Water standards before being released into the sewage system. 21 Energy management Yakult has a commitment to using energy efficiently and wisely for sound environmental and economic reasons. The factory incorporates the latest equipment and techniques to reduce the amount of energy used. For example: • all fluids are heated using heat exchange plates • all machinery is well maintained to function optimally, ensuring that energy is not lost or wasted • no CFCs are used in cooling or refrigeration • off-peak rates are used for utilities whenever possible. For example, the ice bank water storage keeps all water at 0°C using compressors that are run in the evenings, during offpeak rates • Yakult’s boiler uses natural gas and is run for short periods as required (therefore, no pollution is emitted). Source: Yakult Australia Pty Ltd website, http://www.yakult.com.au/product04.htm Questions Question 1 Identify and explain the three key elements of Yakult’s operations management system. In your answer provide one example of each key element. 3 marks Question 2 For each of the three key elements of Yakult’s operations management system that you described in your answer to Question 1, describe one ethical or socially responsible management practice that Yakult employs. Discuss how one of the practices could affect the corresponding element. 5 marks Question 3 Describe the type of facilities layout used at Yakult. Justify your answer. 1 mark Question 4 Yakult purpose-built its factory and office complex in Dandenong in 1993 at a cost of $30 million. Explain one factor that Yakult could have considered in designing the layout of its operations at Dandenong. 1 mark Question 5 Explain one factor that Yakult might have considered when locating its Australian plant at Dandenong. 1 mark Question 6 Explain what is meant by the just-in-time (JIT) approach. Discuss the potential benefits of this approach for Yakult. 3 marks Question 7 Identify and describe two strategies (other than JIT) that Yakult uses or could employ to manage its materials. 2 marks Question 8 Discuss one benefit to Yakult of adopting an ethical and socially responsible approach to operations management. 2 marks Question 9 Explain why productivity would be important to Yakult and its operations. 1 mark Question 10 The Dandenong plant in Victoria is the only factory in Australia and produces products for the Australian and New Zealand markets. Explain how this affects its ability to be competitive in a global environment. 1 mark Question 11 Describe and justify two performance indicators that Yakult could use to measure the efficiency or effectiveness of its operations. 2 marks Question 12 Identify one type of computer-based process technology and explain how it is used or could be applied at Yakult’s Victorian plant to improve efficiency. 1 mark Question 13 A number of quality strategies are mentioned in the Yakult case study. Select two of these strategies and explain how each strategy helps Yakult to optimise its operations. 4 marks Question 14 Analyse how the three central principles of total quality management (TQM) could help optimise operations at Yakult. 3 marks Question 15 a. Distinguish between the operations management system of a service organisation (e.g. hotel or hospital) and a manufacturing organisation (e.g. a ball or car manufacturer). 2 marks b. Identify and justify two strategies that could be used to optimise the operations management system of both a service organisation (e.g. hotel or hospital) and a manufacturing organisation (e.g. a ball or car manufacturer). 4 marks c. Analyse two strategies that a service organisation (e.g. hotel or hospital) or a manufacturing organisation (e.g. a ball or car manufacturer) could use to ensure that its operations are ethical and socially responsible. 4 marks Total: 40 marks