5.04.08 OPT A New Alternative Material

advertisement

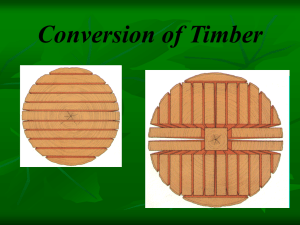

Oil Palm Trunks a New Alternative Material for Solid Wood Products Edi Suhaimi BAKAR,1 Mohd. Hamami SAHRI,1 Zaidon ASHAARI,1 and Fauzi FEBRIANTO2 1 Department of Forest Production Faculty of Forestry, Universiti Putra Malaysia 43400 UPM Serdang, Selangor, Malaysia 2 Department of Forest Products Technology Faculty of Forestry, Bogor Agric. University, PO. Box 168, Bogor, Indonesia Introduction ● Wood supply issues: Shortage of wood supply, especially for solid wood Production from forest no longer sufficient to meet the demands Finding the alternative material of wood has become a central issue Any alternative must be sought– include agricultural residues. ● Oil palm trunks (OPT) as strategic wood alternative material: Huge oil palm planted area By 2006: Malaysia = 4.2 million ha, Indonesia = 5.4 million ha Replanting at 25 years old: average annual rate 4% Produce huge amount residues (fronds, EFB, trunk) Trunk offer the best properties comparable to the wood About 250m3 OPT for each replanting hectare (most under utilized) Introduction ● Characteristics of matured oil palm trunks: Consist of two main structure: - vascular bundles- thick walled cells → high density - parenchyma tissues- thin walled cells → low density, more porous and starch Vascular bundles are scattered in parenchyma tissues as matrix, with a reduced concentration from the outer to the inner Great density gradient between trunk’s outer part (0.4 g/cm3) and center part (0.15 g/cm3). Only the trunk’s outer part can be used as solid wood (Bakar, 2000) ● Characteristics of oil palm wood (OPW): Very low in strength Bad in dimensional stability Very low in durability Poor in machining characteristic Need properties improvement Objectives & Methods ● To develop suitable sawing pattern for OPT ● To enhance the properties of OPW Objectives & Methods ● To develop suitable sawing pattern for OPT Being monocot (the best portions of wood at the outer part) the available sawing patterns can not be used for OPT Three sawing patterns are compared (two are modified patterns): - Live sawing (LS) - Polygon sawing (PS) - Cobweb sawing (CS) Test materials: (CS) (LS) (PS) - 12 logs from 4 oil palm trees of 25-year-old (L: 2.5 m, D: 43–55 cm) - The logs ends were paint-coated in different color Measurements: - Lumber Recovery: Outer-lumber, Middle-lumber, Center-lumber - Sawing time: Effective time, Ineffective time, Total time - Lumber width count occurrence of each width criteria of the outer lumber Oil palm log Objectives & Methods ● To enhance the properties of OPW Material - The outer lumbers OPW (0.33–0.4 g/cm3), dimension (40Tx100Rx100L) mm - Mmw-PF of various concentrations Methods Modified Compreg Drying Impregnation Re-drying Hot-pres Densification MODIFIED COMPREG - Drying: 15% - Impregnation - Concentration : 10, 15, 20 % - Period : 1, 2, 3 hrs - Compression : 120 psi - Re-drying (microwave, 1kWh) → partially cured resin - Period : 5, 7, 10, 15 min - Power output : high - Hot pressing - Temperature : 150°C - Pressing time : 30 min - Pressing ratio : 50% (45%) Results & Discussion Sawing Study ● LS provided the highest RT but the lowest RO. Two-thirds of the R-outer (RO) R-midle (RM) R-center (RC) R-total (RT) 80 results were the middle- and center-lumbers that were low in 60 quality. 40 ● CS produced the lowest RT (50%) but the highest RO (35%). Two20 thirds of resulted lumbers were 0 the outer-lumbers that were high LS PS CS in quality Sawing patterns ● PS was in between, about half of resulted lumbers were the outer lumber ● CS is the most suitable sawing pattern in term of outer lumber recovery. Lumber Recovery (%) 100 Results & Discussion Sawing Study ● LS consumed the shortest time and CS pattern the longest in T-efective (Te) T-inefective (Ti) term of either the Tt or the Te. T-total (Tt) 45 ● PS consumed about the same Te (6.7 min.) to the LS and the same 30 Tt (46.0 min.) to the CS 15 ● CS consumed as twice as longer Te (15.4 min.) than the LS and PS 0 ● Both PS and CS patterns spent LS PS CS plenty of Ti (39 min.) Sawing patterns for cant adjustment. ● The LS is the most suitable sawing pattern in term of the sawing time. Sawing Time (min.) 60 Results & Discussion Sawing Study 41 25 Width Count 20 > 20 cm 11-15 cm < 5 cm 16-20 cm 5-10 cm 15 10 5 0 LS PS Sawing patterns ● LS and CS tend to produce narrow strips which is consider low in quality, while PS pattern tend to produce wider lumber which is high in quality: Board <10cm: LS (77%), CS (88%), PS (47%) Board >20cm: CS (0pc), LS (1pc), PS (3pcs) CS ● The PS was the most suitable sawing pattern in term of the outer lumber width Results & Discussion Sawing Study POLYGON SAWING ● After considering all the parameters above, it can be concluded that the Polygon Sawing is the most suitable pattern for the sawing of OPT. (PATENT P.20001099) ● The Polygon Sawing can produce wide outerlumbers which are high in quality, with recovery of 27%. ● Skilled operators and good carriage are needed to run the Polygon Sawing efficiently. ● Potential OPW production in Malaysia: = 4,2 millions x 4% x 250m3 x 27% = 11.34 million m3/year Results & Discussion Properties Enhancement Study 50 1 hr 2 hrs 3 hrs WPG (%) 40 30 20 10 0 10% 15% PF Concentration 20% ● Being impregnated and densified, the density of OPW increased almost 3x from 0.37 g/cm3 to almost 1.00 g/cm3. ● The amount of PF resin penetrated, WPG, depend on PF concentration and impregnation period. ● These result suggested that 1-2 hrs impregnation was sufficient to impregnate the mmw-PF into OPW structure. ● This is a very short period compare to impregnation of softwood that need 24 hrs even with a lmw-PF resin as reported by Furuno [3]. Results & Discussion Properties Enhancement Study 50 1 hr 2 hrs 3 hrs ASE (%) 40 30 20 10 0 10% 15% PF Concentration 20% ● Anti swelling efficiency (ASE) that indicate dimensional stability achievement of treated OPW was 30% ● There was no significant influence in increasing the solution concentration and impregnation period to the ASE value ● These suggested that short impregnation (1 hr) with low concentration mmw-PF resin (10-15%) is good enough to enhance the dimensional stability of OPW Results & Discussion Properties Enhancement Study The mechanical properties of treated OPW were substantially improved 3000 16 2 hrs 3 hrs 1 hr 2 hrs 3 hrs 2500 Shear strength (MPa) Compression // grain (MPa) 1 hr 2000 1500 1000 12 8 4 500 Ctr= Ctr= 0 170 10% 15% PF Concentration 20% 1.85 0 10% 15% 20% PF Concentration ● Young’s Modulus at the compression parallel to the grain increased from 170 to 2600 MPa ………..(15x) ● Shear strength increased from 1.9 to 13 MPa ………… (7x) Results & Discussion Properties Enhancement Study ● Even the mmw-PF might not penetrate into vascular bundles, it could immediately penetrate into the parenchyma tissues. ● PF penetration to parenchyma tissues improve density/strength, durability and dimensional stability of whole OPW, and reduces density gradient between the vascular bundle and parenchyma tissues. ● Reduction in the density gradient resulted in better machining characteristic. ● The method can practically solve the four OPW flaws concurrently. UNTREATED OPW TREATED OPW Conclusions ● The outer-part of OPT provide the best quality wood (OPW) that can be used as solid wood after properly treated. ● Polygon sawing is the best suited pattern to saw OPT. Sawing recovery of 27% can be achieved. ● Potentially about 11 million m3 OPW timber can be resulted in Malaysia annually. This timbers have four flaws that need to cope with before utilization. ● Modified compreg method with mmw-PF can solve all OPW flaws concurrently. ● Treated OPW timbers can be used as a new alternative material for diminishing solid wood. ● Utilization of OPW (upon treatment) may reduce our dependency on wood from the forest, and at the same time could solve the facing problem in the plantation industry. References [1] Bakar, E.S., Y.S. Hadi. 2001. Indonesian J. For. Prod. & Techno. Vol. XIV (2): 24-31. [2] Ibach, R.E. 2005. Lumen Modifications, In Rowel, R.M. (Ed.), Handbook of Wood Chemistry and Wood Composites. Taylor & Francis. N.Y. [3] Furuno, T., Y. Imamura, H. Kajita. 2004. Wood Sci. Technol. 37: 349-361. [4] Bakar, E.S., P. Md. Tahir, and Mohd. H. Sahri. 2005. Internat. Sympo. on Wood Sci. and Techno. Yokohama, Nov. 27-30. [5] Rahaya, I.S. 2001. Basic Properties of Vascular Bundles and Parenchyma of Oil Palm Wood. Thesis at School of Graduate Study, Bogor Agric. Univ. (IPB), Indonesia.