1. Statistik Listrik 2012 .Accessed in 12 november 2012. From ESDM

advertisement

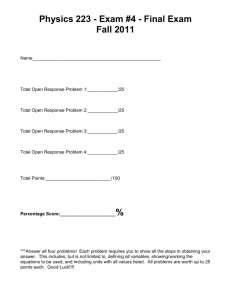

Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 JOURNAL OF BACHELOR DEGREE THESIS Febrian Aliandi 20409053 MECHANICAL ENGINEERING DEPARTMENT GUNADARMA UNIVERSITY 2013 Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules Page 1 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 UTILIZATION THE SEEBECK EFFECT WITH TEALIGHT CANDLE HEAT SOURCE USING 4 THERMOELECTRIC MODULES Febrian Aliandi Mechanical engineering department, Gunadarma University Depok – Kelapa Dua Email: aliandi20@gmail.com ABSTRACT Thermoelectric TEC12706 commonly used as a cooling device change the electric input into temperature difference at each side. However, TEC12706 can still generate electricity in low temperature. The device will generate an electricity if there have temperature difference in different side of the module, the output of electricity occurs due to the transfer of energy from the semiconductor N type to P-type with smaller energy, the experiment was conducted to find out the potential can generated utilize a heat of burning tea light candle into electrical energy using 4 thermoelectric module. The type of heat sink and coefficient of natural convection affect the temperature difference during the experiment. Data obtained from the experiment are voltage, current, temperature, temperature difference, and electricity power to be processed using empirical equations thus obtained as a result of processing. From the results of the experiment, average value data of the prototype from experiments 2 candles series circuit ∆T = 10.8 oC, V = 2.7 V, I = 8.62 mA, P = 0.024 Watt, 3 candles series circuit ∆T = 10.85 oC, V = 2.98 V, I = 8.063 mA, P = 0.027 Watt. 2 candles series-parallel circuit: ∆T = 9.9 oC, V = 1.4 V, I = 22.2 mA, P = 0.03 Watt. 3 candles series-parallel circuit ∆T = 13.7 oC, V = 1.7 V, I = 29.2 mA, P = 0.052 Watt. The graph shown is the relationship between electrical output with the time in which bigger value of the temperature difference then the higher output generated, as long as the hot temperature through the module on the work temperature range efficiency of the Thermoelectric module. Some of the factors that affect large output are hot temperature, ambient temperature, the State of the wind around, the amount of heat energy received by TC and the type of electrical circuit. BACKGROUND how much potential heat from a candle to generate Nowadays Technology developed rapidly electricity with 4 thermoelectric module. Problems causing an increasing of energy needs, especially emphasized in the electricity needs of the electronic electrical energy. The main used energy source gadgets or small electronic device. As well as nowadays sourced on a nonrenewable energy such as knowing how a series of thermoelectric generator fossil fuel or natural gas. From fossil fuel or natural generates electricity from the temperature difference gas energy, produce an air pollution that can make a in two different sides. global warming and stock of that energy sources are decreasing every year. Thermoelectric Technology is LITERATURE REVIEW one of an alternative energy source to answering Basic Thermoelectric these energy needs. That technology relatively more Thermoelectric have two working system environmental friendly, no moving part, the forms is using seebeck effect and peltier effect. relatively small and compact, durable, can absorb the effect make a Temperature difference become a heat that is not needed in a system and is also able to DC electrical energy directly. When 2 dissimilar produce energy on a large and small scale. When material give a heat energy in one side the the electrical source are off, mostly use a candle to light energy will moved to different side like Figure 1.1, up the room so this final assignment wanted to know the temperature different between two dissimiliar Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules seebeck Page 2 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 material will produce a potential electricity in the increasing the efficiency of the cooling system junction. TEM and increasing the output, because a better α = ∆s⁄∆T 𝑎 heatsink will cause a bigger temperature difference With : on the hot side and the cold side of the = Seebeck coefficient from material (V/oC), thermoelectric generator system. Based on it, the ∆V = electrical potential (V), ∆T = temperature different (oC). heatsink must have good heat conductivity to be able to absorb the heat from the hot side then take it off to the air around, lightweight, not easily deformed then select heatsink material with aluminum. On the convection heat transfer Newton cooling law is applicable, where:[12] 𝑞 = ℎ. 𝐴 (𝑇𝑠 − 𝑇∞ ) where: q = heat energy (W) h = convection heat transfer Coefficient (W/m2. ° C) A = surface area (m2) MATERIAL SELECTION TS = surface temperature (°C) TEM Selection 𝑇∞ = ambient Temperature (surrounding air) (oC) Figure 1.1 Illustration of seebeck effect, thermoelectric generator. [4] Peltier element or Thermoelectric module (TEM) is used as it is in the market namely TEC112706 with dimensions of 40 x 40 x 3.5 mm. Material constituent of peltier elements Thermal Collector is This tool serves as a Thermal collector of generally from a semiconductor material bismuth heat candle and as a conductor of heat to the peltier telluride and the surface with a ceramic material element and also serves as a place of TEM and part Al203. The form of TEM look like a wafer 2 of the frame of the tool. TC requiring materials that surfaces with ceramic material and between 2 are capable of absorb heat quickly, ability of take a surfaces there is a bismuth telluride semiconductor load, and TC should be able to hold the combustion P and N. heat flow from the candle, so the heat flow from a candle not reach the heatsink which can causing the Heat Exchangers heatsink gets a heat from aother system than the Heatsink serve as a release of heat from heat from the surface of TEM. Because these TEM into the air around, giving it a larger size reasons selecting a TC profiled like the letter V because to make the release of heat into the air made from aluminium material. around better. The Heatsink also helps in Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules Page 3 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 ṁ = mass burning rate of the fuel (g/m) Hc = net heat of complete combustion of the fuel (Kj/g) ∆Hceff = effective heat of combustion(Kj/g) m = mass of the candle (g) Table 1.1 properties of Paraffin candle wax [14]. Figure 1.2 design concept Tealight Candle This candle is commonly used as a burner of aromatherapy, as a warmer for food and drink, as aromatherapy in scented tealight candle, as a light for the room and many more. This candle used as a heat source and then convert into electricity by thermoelectric module. This type of candle used because availability on the market with a relatively inexpensive price, and shrinkage of wax this kind of candle is small so not needed significant setup the distance between candle and TC. The candle made by a white paraffin wax unscented. The dimensions of this candle length of the wick 10 mm and 17 mm tall, diameter 37 mm, weight about 14-19 grams and a burning duration about 4 - 5 hours. The burning candle, burn paraffin as a fuel and produce a heat into surrounding air. Assuming the candle fully burned, where there is no scrap of wax while candle burned that mean a value of candle burning efficiency is 1 calculate the heat energy from candles with: q = 1 x m x Hc With : Ǭ = effective heat release rate (Watt) Xa = combustion efficiency EXPERIMENTAL SETUP After the prototype assembled need a tools that can measure output performance of the prototype and need a tools that can reach small place to measure a temperature of the TEM surface, hot an cold side of TEM. The output measured by a mutimeter, 1 measure a voltage output and other one measure current electricity output of the prototype. The electrical data is an open circuit with measuring current electricity with a delay about 1-10 seconds after all the hold button of other tools pressed. Temperature measured by a thermocouple and data logger, placed on the TEM number 2 and 4 as represent of all the temperature of TEM. Candles used 2 and 3 candles placed on a bottom with a distance about 30-32 mm from TC, Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules Page 4 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 distance of 1 candle to other is about 10 – 11 mm voltage and current captured every 1 minute. From this to keep the a candle not given a heat energy data can calculate temperature difference, heatsink from other candle. Data record from 1 minute to 30 heatrate, and power electricity. minutes, the data temperature hot and cold side Figure 1.3 the entire tools installation completed. EXPERIMENTAL RESULT Temperature Difference Analysis Graph of temperature difference of some data that obtained from experiments results are as follows: 18 16 12 10 8 6 4 2 0 Tempereature Difference(oC) 14 0 Time(Minute) 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 2 candles series 3 candles series 2 candles series parallel 3 candles series parallel Figure 1.4 value of temperature difference (∆T) against time with different candles and circuit of TEM. From figure 1.4, adding more candle as a caused the wind flow through the candle. The wind heat source can increase temperature difference in the experiment room cannot maintain nicely. generated, on experiment using 3 candles series The wind can affect heat given to TC. circuit, the heat dropped lower than other, that maximize the heat from the candle as mentioned Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules To Page 5 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 earlier should be applied a wind protection so that alumina ceramic which, have a good ability to the flame of the candle stable. From figure 1.4, absorb heat but bad thermal conductivity, the heat bigger thermal energy can caused a bigger absorbed from TC bigger than heat transferred to temperature difference to the prototype, this caused other surface, so that caused the temperature by an ability of material to conduct thermal energy difference of two surface become bigger. to transfer heat to heatsink. TEM Surface made by Output voltage Analysis Graph of output voltage data that obtained from experiments results written in appendice 4 are as follows: 5 4.5 4 3.5 3 2.5 2 1.5 1 Voltage 0.5 0 Minute 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 2 candles series 3 candles series 2 candles series - parallel 3 candles series - parallel Figure 1.5 value of voltage against time, with different candles and circuit of TEM. From figure 1.5 looked the series circuit difference is same the output will decrease. The has a bigger voltage output then series parallel experiment of 3 candle series from minutes 10 – because its characteristics is have a bigger voltage. 20 the circuit have a low voltage output, like Voltage is decreased every minute of the mentioned before the fire of the candle swinging experiments, that caused by a work temperature from figure 1.3 the temperature difference are Efficiency limitation of TEM. TEM have a lower than using 2 candles too, that causing the limitation working temperature efficiency to output have a lower output. However, at minute raising the electrical output. When efficiency 20 – 30 the fire stable and the temperature work temperature elapsed, even the temperature difference Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules raised. Page 6 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 Output Current Analysis Graph of output current of some data that obtained from experiments results written in appendice 4 are as follows: 50 45 40 35 30 25 20 15 5 0 Current(mA) 10 Minute 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 2 candles series 3 candles series 2 candles series-parallel 3 candles series-parallel Figure 4.5 value of current against time, with different candles and circuit of TEM. . From figure 4.5 looked from experiment temperature efficiency limitation. The current used 2 and 3 candles of series-parallel circuit output from experiments with 3 candles series, gotten a bigger current than series circuit. Series – from the graph that looked the current lower than parallel circuit are mixed characteristics of series 2 candles series experiment, that caused like and parallel circuit so if this circuit used the mentioned before the fire during the experiments balance voltage and current will got. The biggest quite unstable so causing the output unstable. The current output occurred only at the beginning of current Output obtained from the experiments the between 10 – 40 mA. experiments mentioned before, around TEM 1-4 minute. have a Like working Output Power Analysis From the current and voltage data obtained from the experiment, can find how much electrical power output generated of the prototype can calculated with the equation 2.7 as follow: Pgen = I2 Rload = I x V Where: I = output current (A) V = voltage/output voltage (V) Pgen = power generated (Watt) Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules Page 7 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 After calculated the power output, graph of output power of some data that obtained from experiments results written in are as follows: 0.12 0.1 0.08 0.06 0.04 Power (Watt) 0.02 0 Minute 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 2 candles series 3 candles series 2 candles series - parallel 3 candles series parallel Figure 1.7 value of power against time, with different candles and circuit of TEM. Figure 1.7 is the result of the calculation experiment using 2 candles and the put can rapidly between voltage multiplied by a current output, and raised too. From figure 1.7, experiment series the result is an open circuit power without any load parallel circuit have a biggest power than other at on a circuit. From figure 1.7 using 3 candles mean the end, that because series – parallel circuit have a produce much more heat energy given to the TC, 2 characteristic mixed, big voltage from series so TC temperature can rapidly raised than circuit and big current from parallel circuit . Calculation and Analysis of Heat Transfer On the Heatsink The measurement of the heatsink done 2 times, the data obtained from experiment on the heatsink divided by 2 so got the mean temperature data. The change of heatsink temperature draws on the graph as follow: 120.0 100.0 80.0 60.0 Temperature OC 40.0 20.0 0.0 Minute 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 30 3 candles 2 candles Figure 4.7 heat sink temperatures against time during the experiment. Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules Page 8 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 The values obtained from the calculation of heatsink heat rate during the experiment written in appendice 5 are as follows: Heat rate (Watt) 18 16 14 12 10 8 6 4 2 0 0 2 Minute 4 6 8 10 12 14 16 18 20 22 24 26 28 30 3 candles 2 candles Figure 4.8 heat sink heat rate during the experiment. From figure 4.8 showed more burning candle can candles series-parallel circuit: ∆T = 9.9 oC, V = 1.4 affect more heat rate of the heatsink. Experiment V, I = 22.2 mA, P = 0.03 Watt. 3 candles series- using 3 candle the heat rate more higher than using parallel circuit ∆T = 13.7 oC, V = 1.7 V, I = 29.2 2 candles, this is due to the addition of the candles mA, P = 0.052 Watt. will got bigger value of heat produced because the theory of Q absorb = Q waste. The assumption in this calculation is the fluid air as ideal gas, Th REFFERENCES 1. Statistik Listrik 2012 .Accessed in 12 constant and natural convection. november 2012. From ESDM website, www.esdm.go.id. 2. Terry Hendricks William T. Choate, 2006, 5.1 Conclusions From the results of experiments and Engineering Scoping Study of Thermoelectric calculations concluded several things Bigger Generator Systems for Industrial Waste Heat temperature difference is given to the TEM, then it Recovery. will be bigger the voltage and current are generated and increased the power generated. addition of heat source can make bigger temperature difference then generate bigger voltage, current and power 3. G. Jeffrey Snyder, Tristan S. Ursell, Thermoelectric Efficiency and Compatibility. 4. www.lairdtech.com , Thermoelectric Handbook. output. Series circuit of TEM have bigger voltage 5. putra nandy,artono koestoer raldi, potensi daya output. Usea candle as a heat source is applicable termoelektrik untuk kendaraan hybrid, 2009. with any weakness like a wind flow. Average value 6. Seebeck Effect . Accessed in 13 oktober 2012, data of the prototype from experiments 2 candles series circuit ∆T = 10.8 oC, V = 2.7 V, I = 8.62 mA, from Wikipedia website. www.wikipedia.org 7. Thermoelectric Effect. Accessed in 13 october P = 0.024 Watt, 3 candles series circuit ∆T = 10.85 2012, o www.wikipedia.org . C, V = 2.98 V, I = 8.063 mA, P = 0.027 Watt. 2 from Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules Wikipedia website. Page 9 Thesis Journal, Mechanical engineering department, Gunadarma university, Depok-Kelapa dua Student ID 20409053 8. Thermoelectric 1-12706 propierties, HB corp. 12. Cengel, Yunus.A., Heat And Mass Transfer: 9. Thermoelectric Technical Refference-Power A Practical Approach Third Edition (Si Unit), Generation. Diakses 20 oktober 2012, dari ferrotec. www.ferrotec.com McGraw-Hill, Inc. New York, 2006. 13. Hamins Anthony and Matthew Bundy, 10. Power Generation. Diakses 20 oktober 2012, dari Powerchips. www.powerchips.com. Characterization of Candle Flames. journal ,National Institute of Standards and 11. Mastbergen Dan, Willson Bryan, Generating Light from Stoves using a Thermoelectric Technology Gaithersburg USA. 14. Piotr Dziurdzia , Modeling and Simulation Generator, journal, Engines and Energy of Conversion of Processes, journal, AGH University of Colorado State Science and Technology in Cracow, Poland. Laboratory Mechanical Engineering Department Thermoelectric Energy Harvesting University. Utilization The Seebeck Effect With Tealight Candle Heat Source Using 4 Thermoelectric Modules Page 10