Legislation

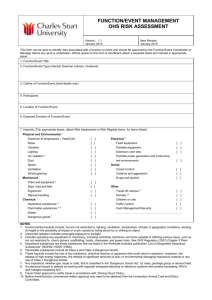

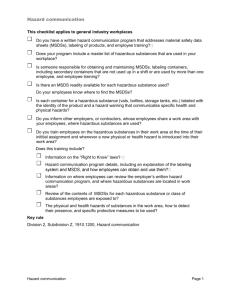

advertisement

Department of Education Safe Use of Machinery in Technology Teaching Program Purpose • To be able to test and demonstrate knowledge in the safe use of static powered machinery • To have an understanding of safety requirements according to current Victorian legislation Learning Outcomes VBQU618 Apply OHS principles to technology teaching • Describe technology area roles and responsibilities of employers, employees, and contractors as set out in occupational health and safety legislation eg. technology head, health and safety representative, technology teachers, management nominee • Maintain awareness of all relevant OHS Risk Management requirements for managing risks in technology • Develop understanding of hazards in technology and the application to machinery safety • Learn about the management of hazardous substances in the technology teaching environment Learning Outcomes VBQU619 Safely operate and maintain woodworking machines • Learn about preparing, operating and maintaining woodwork machinery, including basic machinery safety • Develop understanding of managing safety in a woodwork teaching workshop • Implement housekeeping procedures in a technology teaching environment and safe operation of all common woodwork machinery Learning Outcomes VBQU619 Safely operate and maintain metalworking machines • Understand metal shop safety in the technology teaching environment and safe operation of all common metalwork machinery • Learn about preparing metal working machines for use • Learn about operating, maintaining metal working machines • Implement housekeeping procedures in a teaching metal shop Session 1 VBQU618 Apply OHS Principles to Technology Teaching Legislation • Acts • Regulations • Compliance Codes • Standards • Guidance • Agreements and contracts WorkSafe Victoria • WorkSafe Victoria is the Victorian WorkCover Authority’s occupational health and safety arm • Responsibilities include: - prevent workplace injuries - enforce Victoria’s OHS Laws S2 Objects of the OHS Act 2004 a) to secure the health, safety and welfare of employees and other persons at work b) to eliminate, at the source, risks to health safety or welfare of employees and other persons at work c) to ensure that the health and safety of members of the public is not placed at risk by the conduct of undertakings by employers and self-employed persons d) to provide for involvement of employees, employers and organisations representing those persons in the formulation and implementation of health, safety and welfare standards Principles of Health and Safety Protection 1 All people must be given the highest level of protection against risks 4 Employers and employees should exchange Information and ideas about risks 2 Those who control or manage the workplace are responsible for eliminating or reducing risks as far as is reasonably practicable. S4 3 Employers and self-employed persons must be proactive 5 Employees are entitled, should be encouraged to be represented Concept of Ensuring Health and Safety S20 • Eliminate risks to health and safety so far as is reasonably practicable If not reasonably practicable to eliminate risks • Reduce risks so far as is reasonably practicable Note: health includes psychological health S20 When determining what is Reasonably Practicable regard must be had to … a) likelihood of the hazard or risk eventuating b) the degree of harm that would result if the hazard or risk eventuated c) what the person concerned knows, or ought to reasonably know about the hazard or risk and ways of eliminating or reducing it d) the availability and suitability of ways to eliminate or reduce the hazard or risk e) $ the cost of eliminating or reducing the hazard or risk $ S21(1) Duties of Employers An employer must, so far as is reasonably practicable, provide and maintain for employees of the employer a working environment that is safe and without risks to health*. * Definition of health includes psychological health S21 (a-e) Duties of Employers Employers must so far as is reasonably practicable: • provide or maintain plant or systems of work • manage risk when using, handling, storing and transporting plant or substances • maintain workplaces under their control and management in a safe and healthy condition • provide adequate facilities for the welfare of employees • provide information, instruction, training or supervision to employees to perform their work that is safe and without risks to health S21(3)(a) Contractors “Employee” includes an independent contractor engaged by an employer and any employees of the independent contractor S21(3)(b) Contractors • the duties of an employer under those sub-sections extend to such an independent contractor and the independent contractor’s employees, in relation to matters over which the employer – has control; or would have had control but for any agreement between the employer and the independent contractor to limit or remove that control. S22 Duties of Employers An employer must so far as is reasonably practicable • monitor the health of the employees • monitor the conditions at the workplace • provide information to employees (in appropriate languages) concerning health and safety at the workplace, including the names to whom an employee may make an enquiry or complaint about health and safety • keep information and records relating to health and safety of employees • employ or engage qualified people to provide advice on occupational health and safety S25 Duties of Employees • Take reasonable care of themselves • Take reasonable care of others who may be affected by their acts or omissions • Co-operate with their employer on safety matters • Not to intentionally or recklessly interfere with or misuse anything provided at the workplace in the interests of health, safety or welfare • In determining failure to take reasonable care regard must be had to what the employee knew about the relevant circumstances Employers and Self Employed Persons S23&24 Responsibility to ensure that persons (other than employees) are not exposed to risks arising from conduct of their undertaking S27 Duties of Designers of Plant • Must ensure that the plant is designed to be without risks to health and safety when used for the purpose it was designed. • Must carry out tests and examinations to ensure that the plant is safe when used for its intended purpose. • Must provide information about the intended purpose of the plant, test results and any conditions necessary to ensure that it is safe when used for the intended purpose. Duties of Manufacturers of Plant or Substances S29 • Must ensure that plant and substances are safe when used for the purpose they were manufactured • Must carry out or arrange tests and examinations to ensure that the plant/substance is safe when used for intended purpose • Must give suppliers and users of plant or substances information about: the intended purpose(s) of the plant or substances, the results of tests for plant or substances; and any condition necessary to ensure that when used for intended purpose they are safe. S40,41&42 Licences, Registration and Permits • Employers must not allow work to be carried out unless the workplace activity, plant or substance is licensed or registered as required under the relevant regulations. • An employer must not allow the person to work unless the person has the required training, qualification, permits or supervision. Penalties Companies Individuals • • maximum $991,080 5 years jail • maximum $198,216 The value of a penalty unit is $110.12 July 2007 Workplace Consultation and Workplace Representation (Duties to consult commenced January 2006) Consultation S35&36 Employer must Consult employees on OHS matters that directly affect them especially for: • Health monitoring • Workplace environmental monitoring • Providing information and training • Membership of any health and safety committee • Proposed changes – workplace, plant, substances, other things, conduct of work performed Consultation S35&36 Employer must Consult employees on OHS matters that directly affect them especially when: • Identifying or assessing hazards and risks • Making decisions about control measures • Making decisions about the adequacy of facilities • Issue resolution procedures • Consultation procedures Issue Resolution and Roles of Inspectors Workplace Issue Resolution Duties of Employers • employer’s representative is not a health and safety representative has an appropriate level of seniority is sufficiently competent resolve health and safety issues S73(2) Workplace Issue Resolution Employer and employees affected by the issue must attempt to resolve the issue Step 1 • Employee raises an issue with supervisor and/or health and safety representative and/or management representative (note that an employee from another DWG can raise an issue with another DWG health and safety representative) Workplace Issue Resolution Step 2 • Issue is reviewed and is resolved – acceptable solution is implemented Step 3 • Issue is not resolved – health and safety representative can issue a PIN Step 4 • Inspector can be called in to resolve the issue Issue Resolution Flow Chart Roles and Responsibilities of WorkSafe Inspectors • Monitor and enforce compliance with OHS legislation • Provide information and advice to workplace parties • Assist in resolving OHS issues and disputes • Investigate incidents and complaints • Initiate prosecutions, as required Technology Area eg. Inspectors may be looking for • Unsafe machinery • Storage of hazardous substances • Storage of materials • Safe work practices Inspectors General Powers of Entry (a) (b) (c) (d) (e) (f) (g) (h) inspect, examine and make enquiries inspect and examine any thing bring any equipment or materials seize any thing (including documents) seize any thing for further testing or examination take photographs and measurements, make sketches and recordings exercise any other power any other thing that is reasonably necessary S99 Directions and Notices issued by Inspectors • Directions Verbal or written Directions if there is an immediate threat to health and safety • Non-Disturbance Notice Stop use, movement of, interference with any plant, substance or thing (no more than 7 days) • Improvement Notice Situation must be remedied by a given date, can include directions and interim directions and conditions • Prohibition Notice Prohibits the carrying on of an activity, or the carrying on of the activity in a specified way Session 2 Plant Safety Controlling OHS Hazards & Risks Hazard the potential to cause injury, illness or property damage Hazards Examples of hazards: • air borne contaminants • noise • dangerous chemicals or harmful substances • moving vehicles • manual handling • oil spills • naked flames • operating machinery Hazard Groups • Physical noise, vibration, lighting, electrical, temperature, radiation, machinery, fire and explosion • Chemical gases, dusts, fumes, vapours, liquids • Ergonomic manual handling, workplace layout, equipment design, workstation design • Biological Infections, bacteria, viruses • Psychological stress, personal threat Physical Hazard - Noise Effect on Hearing Very Dangerous Sound Level in dB(A) Typical Sound Source 140 130 Jet Engine Rivet Hammer 120 Aircraft Propeller 110 100 90 Rock Drill Chain Saw (2-stroke) Sheet Metalwork Heavy Truck Risky 85 80 Noise exposure standard Heavy Traffic Irritating 70 Family Car 60 50 40 30 20 10 0 Normal Conversation Quiet Conversation Background Radio Whispering Quiet Room Rustling Leaves Silence PAIN LEVEL Dangerous Physical Hazard - Vibration • Whole body • Segmental • White finger Technology Hazards • • • • • • • • Poor design Cutting Crushing Striking Protrusions stabbing Impact Abrasion friction Entanglement Physical Hazard - Electric Cause Death and Serious Burns Prevention • Check power tools and leads • Test and tag • Use qualified electricians • Use Earth Leakage Circuit Breakers (ELCBs) • Use rubber insulation • Establish safe work practices Physical Hazard - Light • Australian Standard 1680 – Interior and Workplace Lighting • Amount of light • Number and position of lights • Interior lighting • Tasks and activities performed Temperature Cold 21°C Hot 26°C 16°C 30°C Comfort Range Physical Hazard Slips, Trips and Falls • • • • Spills Cleaning agents Poor housekeeping rushing • • • • Heights Ladders Lighting Floor coverings Chemical Hazards • Gases- oxygen, acetylene, nitrogen • Solids - metals,minerals • Liquids - acids, alkalis • Dust - asbestos, wood dust • Mist - paint spray • Vapour - petrol Ergonomic Hazards Fit the workplace to the worker NOT the worker to the workplace Ergonomic Hazards • Use mechanical handling devices rather than physical (manual) handling Hazard Identification • • • • • • • • workplace inspections product information reports incident - illness - injury legislative requirements employees personal knowledge experience and observation industry/trade associations, unions consultant reports health & safety committee minutes Risk • Means the likelihood of injury or illness arising from exposure to any hazard Risk Assessment The following needs to be considered: • • • • • Who is exposed to the hazard? How often are people near the hazard? Has this hazard already caused any problems? How easily could someone be hurt? How common is it for this hazard to cause problems in other workplaces? • Which factors relating to that hazard need to be taken into account, according to health and safety law? • Which factors or specific aspects of the work are increasing the likelihood of injury or illness? Step One - Likelihood A. Very likely - expected to occur B. Likely - will probably occur C. Moderate - might occur D. Unlikely - could occur E. Rare - may occur Step Two - Consequence 1. Insignificant - no injuries 2. Minor - first aid 3. Moderate - medical treatment 4. Major - extensive injuries 5. Catastrophic - death Step Three – Risk Table Consequence Likelihood Very likely Likely Moderate Unlikely Rare A B C D E Extreme risk High risk Moderate risk Low risk Insignificant 1 H M L L L Minor 2 H H M L L Moderate 3 E H H M M Major 4 E E E H H Catastrophic 5 E E E E H consider stopping work should be reduced as soon as possible management responsibility and action dates must be specified manage by routine procedures Hierarchy of Control • • • • • Elimination Substitution Engineering Administrative Personal Protective Clothing and Equipment What are the key features of the Plant Regulations? • No mandatory government approval or inspection of plant • No mandatory requirement for compliance with the relevant Australian Standards • Specified duties for designers, manufacturers, importers and suppliers of plant, employers, and the self-employed “Performance based” legislation • Does not specify minute detail • Sets the standard • Flexibility in developing solutions • Code of Practice for Plant 1995 • Australian Standards or equivalent • Alternative methods What is plant? As defined under the OHS Act 2004 • includes any machinery, equipment, appliance, implement and tool • any component of any of those things; and • anything fitted, connected or related to any of those things OHS Regulations 2007 Part 3.5 - Plant What is plant? Plant that processes material, by way of a mechanical action, which – (1) cuts, drills, punches or grinds the material; or (2) presses, forms, hammers, joins or moulds the material; or (3) combines, mixes, sorts, packages, assembles, knits or weaves the material OHS Regulations 2007 Part 3.5 - Plant Do not apply to: • Plant which relies exclusively on manual power for its operation • Plant which is designed to be primarily supported by the hand • Ships, boats or aircraft • Vehicles designed to be used primarily as a means of transport on public roads or rail Employer Duties 1. 2. 3. 4. 5. 6. Plant under their management or control Hazard identification and control of risk Information, instruction and training Consultation with health and safety representatives Review of risk control measures Specific risk control duties in relation to: guarding operator controls and emergency stop warning devices installation, erection and commissioning of plant use of plant and plant not in use records of inspection and maintenance powered mobile plant rollover protection on tractors electrical hazards lift trucks scaffolds lifts Hierarchy of Controls - Plant • Elimination • Substitution • Engineering Controls • design modification • guarding • enclosures • ventilation • automation • Isolation • Administrative Controls • Personal Protective Equipment Session 3 Manual Handling Health and Safety Problems with Manual Handling physical tiredness muscular/joint pain & injury back injuries abdominal hernia impact injury Manual Handling Legislative Framework Occupational Health and Safety Act 2004 Occupational Health and Safety Regulations 2007 Compliance Code or Code of Practice for Manual Handling Manual Handling .... any activity requiring the use of force exerted by a person to lift, lower, push, pull, carry or otherwise move, hold or restrain any object. Musculoskeletal Disorder …..means an injury, illness or disease that arises in whole or in any part from manual handling in the workplace, whether occurring suddenly or over a prolonged period of time, but does not include an injury, illness or disease that is caused by crushing, entrapment or cut resulting primarily from the mechanical operation of plant. The Problem with Manual Handling Traditional Approach – Safe Lifting Technique • Assessment mainly for weight and worker capability • No real long term controls and solutions • Workers still have to lift objects • Requires reinforcement and supervision • Pressure of work affects performance OHS Regulations 2007 3.1 Manual Handling Require an employer to: • identify hazardous manual handling activities • implement controls – to eliminate or reduce the risk associated with those manual handling activities • Review the risk control measures Hazardous Manual Handling • repetitive or sustained application of force • repetitive or sustained awkward posture • repetitive or sustained movement • application of high force • exposure to sustained vibration • manual handling of live person or animals • manual handling of unstable or unbalanced loads or loads which are difficult to grasp or hold Risk controls must consider: • postures • movements • forces • duration and frequency • environmental factors Risk Control Once a hazardous manual handling task has been assessed, eliminate or reduce the risk by: • altering the workplace layout • altering the environmental conditions • altering the system of work • changing the objects • using mechanical aids • any mechanical aids • any combination of the above • aroviding information, training and instruction (if the above are not practicable) Session 4 Noise Introduction • High Noise Levels can lead to Industrial deafness Tinnitus (ringing in the ears) Disturbance Immediate damage with very high levels Noise induced hearing loss is preventable Noise Exposure Standard Sound Level dB(A) Duration per Day 85 88 91 94 97 100 103 106 109 112 115 118 121 124 127 130 8 hours 4 hours 2 hours 1 hour 30 minutes 15 min 7.5 min 3.8 min 1.9 min 57 seconds 28.5 secs 14.3 secs 7.1 secs 3.6 secs 1.8 secs 0.9 secs Noise Induced Hearing Loss • Due to damaged nerve cells in the cochlea. • Caused by prolonged exposure to loud noises. • It can be temporary or permanent. Temporary hearing loss will return after 4 to 20 hours rest. • Noise induced hearing loss is usually slow, painless and permanent. It cannot be cured. It can be prevented. Hierarchy of Control - Noise • Elimination • Substitution • Engineering Controls isolation by enclosures, barriers or vibration isolation mountings any other physical control to reduce noise generation or transmission Administrative Controls increasing distance from the source limiting entry reducing duration to noise exposure other systems of work to reduce noise exposure PPE • • Hearing Protection SLC80 System Noise at the workers ear dB(A) = Measured noise level - SLC80 of PPE Class System Class SLC80dB For use in noise 1 10-13 Less than 90dB(A) 2 14-17 90 to less than 95dB(A) 3 18-21 95 to less than 100dB(A) 4 22-25 100 to less than 105dB(A) 5 26 or greater 105 to less than 110dB(A) Session 5 Hazardous Substances Hazardous Substances Can be: • Chemicals • Dusts • Biological Hazards • Radiation Hazardous Substances Health Effects • Very Toxic • Toxic • Harmful Hazardous Substances Health Effects Corrosive capable of causing damage to living tissue Irritant may cause inflammation or irritation to skin, eye or other tissue Sensitising may cause specific respiratory hypersensitivity or contact dermatitis Hazardous Substances Health Effects Carcinogenic capable of causing cancer Mutagenic capable of causing a change in genetic material in cells (mutation) Teratogenic capable of causing abnormalities in a developing foetus (birth defects) Chemical Labels • • • • • • • • • • Chemical name Active constituents Directions for use Limitations on use Storage and disposal Safety directions and first aid Condition of sale, manufacturer’s name and address Batch number and expiry date United Nations number Dangerous Goods diamonds Material Safety Data Sheets New Format 1. Identification of material and supplier 2. Composition/information on ingredients 3. Hazards identification 4. First-aid measures 5. Fire fighting measures 6. Accidental release measures 7. Handling and storage 8. Exposure controls and personal protection 9. Physical and chemical properties 10. Stability and reactivity 11. Toxicological information 12. Ecological information 13. Disposal considerations 14. Transport information 15. Regulatory information 16. Other information Hazardous Substances Information Read the label Read the Material Safety Data Sheet Find out what the material is before you start working Dangerous Goods Diamonds Dangerous Goods Diamonds Hazardous Substances and Dangerous Goods Summary Hazardous Substances Dangerous Goods Current MSDS at point of use Current MSDS at point of use All containers to be labelled (except if cleaned immediately) All containers to be labelled including Dangerous Goods diamonds Hazardous Substance Register Dangerous Goods Manifest Risk Assessments on use (health effects) Risk assessment on physical and chemical properties, use, handling, storage and disposal Risk to be controlled Physical and chemical risks to be controlled Placarding – depending on the quantity (Schedule 2) Action Planning What things can I do to improve health and safety?