SoM-6.1

Principal Stresses and Strain and

Theories of Failure

Strength of Materials

Prof. A. S. PATIL

Department of Mechanical Engineering

Sinhgad Academy of Engineering, Pune

Strength of Materials 1

Agenda

•

Normal & shear stresses on any oblique plane. Concept of principal planes,

• derivation of expression for principal stresses & maximum shear stress,

•

Position of principal planes & planes of maximum shear.

•

Graphical solution using Mohr’s circle of stresses.

•

Principal stresses in shaft subjected to torsion, bending moment & axial thrust (solid as well as hollow), Concept of equivalent torsional and bending moments.

•

Theories of elastic failure: Maximum principal stress theory, maximum shear stress theory, maximum distortion energy theory, maximum strain theory -their applications & limitations.

Strength of Materials 2

6.1 STRESS ON AN OBLIQUE PLANE

Case 1 – Member subjected to axial load

Normal and Shear force on the plane at an angle Ɵ :-

F

P cos

V

P sin

Normal and Shear stress on the plane at an angle Ɵ

F

A

V

A

P cos

A

0

P cos sin

A

0 cos

P

A

0

P

A

0 cos

2 sin

cos

Strength of Materials 3

Case 2 :- A body subjected to general two dimensional stress system

Stress element showing two-dimensional state of stress

METHODS FOR DETERMINATION OF THE STRESSES

ON AN OBLIQUE SECTION OF A BODY

1. Analytical method

2. Graphical method (Mohr’s circle)

Strength of Materials 4

NOTATIONS

σ y

σ x

Normal Stress in x- direction

σ y

Normal Stress in y- direction

τ

Shear Stresses in x & y – directions

θ

Angle made by inclined plane wrt vertical

σ

θ

Normal Stress on inclined plane AE

τ

θ

Shear Stress on inclined plane AE

σ x

C

τ

D

σ y

θ

P

Inclination of Principal planes

σ

P

Principal stresses

θ

S

Inclination of Max. shear stress planes [θ

S

= θ

P

+ 45 0 ].

All the parameters are shown in their +ve sense in the Fig.

E

τ

θ

σ

B

θ

τ

θ

A

Strength of Materials

σ x

5

SIGN CONVENTIONS

σ x

C

σ y

E

τ

θ

σ

B

θ

τ

θ

A

σ x

τ

D

σ y

Normal stresses, σ

Tensile stresses +ve.

Shear Stresses, τ, in x – direction & Inclined Plane

Clockwise +ve.

Shear Stresses, τ, in y – direction

Anti-Clockwise +ve.

Angle, θ measured w r t vertical, Anti-Clockwise +ve.

All the parameters are shown in their +ve sense in the Fig .

Strength of Materials 6

ANALYTICAL METHOD

σ x

C

τ

D

σ y

E

τ

θ

σ

B

θ

τ

θ

A

σ x

Normal stress on plane AE =

x cos

2

y sin

2

sin

x

2

1

cos 2

2 y

1

cos 2

cos

cos

sin

sin 2

cos

x

y

2

x

y

2

cos 2

xy sin 2

σ y

Shear stress on plane AE =

x cos

sin

y sin

cos

sin

2

cos

2

x

2

y

s in 2

xy c os 2

Strength of Materials 7

PRINCIPAL PLANES

•

There are no shear stresses on principal planes

• the planes where the normal stress (

) is the maximum or minimum

• the orientations of the principal planes (

p

τ = 0

) are given by equating

At

p

x

2

y

s in 2

P

xy c os 2

P

0

.

. .

p

1

2 tan

1

x

2

xy

y

Which gives two values of

Ɵ differing by 90°.

Thus two principal planes are mutually perpendicular

Strength of Materials 8

PRINCIPAL STRESSES

•

Principal stresses are the normal stresses (

) acting on the principal planes (planes which are at an angle of

Ɵp and

Ɵp+90, where the shear stress is zero).

max

min

1

2

x

y

2

x

y

2

R

R where R

x

y

2

2

xy

2

Strength of Materials 9

MAXIMUM SHEAR STRESS

(

max

)

•

To find maximum value for shear stress and its plane (

s

), differentiate the equation of shear stress and equate to zero

x

y

2

s in 2

P

xy c os 2

P d d

x y cos 2

2

xy sin 2

0 tan 2

x

2

y

• orientations of the two planes (

s

) are given by:

Strength of Materials 10

MAXIMUM SHEAR STRESS

(

max

)

s

1

2 tan

1

x

2

y gives two values (Ɵs1 and Ɵs2) differs by 90°

•

Thus maximum shear stress occurs on two mutually perpendicular planes

max

x

2

y

2

2

In terms of principal stresses

max

1

2

2

•

Also, 𝜃 𝑠

= 𝜃 𝑝

+45°

Strength of Materials 11

Case 3 – Member subjected to bi-axial load (τ = 0)

σ y

x

2

y

x

2

y

cos 2

σ x

C E

τ

θ

σ

B

θ

θ

σ x

D

A

x

y

2

s in 2

σ y

•

Principal stresses are at

Ɵp

=0 and

Ɵp

=90

σ1 , σ2 = 𝜎 𝑥 , 𝜎 𝑦

•

Max. shear stress

max

1

2

2

x

y

2

Strength of Materials 12

•

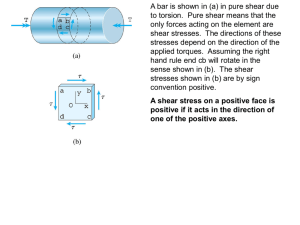

Case 4 – Member subjected to simple shear stress ( 𝜎 𝑥

, 𝜎 𝑦

=0)

C E

τ

θ

σ

B

θ

τ

θ

A

sin 2

τ

D

cos 2

•

For Principal stress,

• 𝜃 𝑝

=45,135

cos 2

1

0

2

Strength of Materials 13

Orientation of Maximum Shear Planes

Maximum Shear

s2

90

s1 x

Strength of Materials 14

Principal Planes & Maximum Shear

Planes

45 Principal plane x

Maximum shear plane

p

= s

±

45

Strength of Materials 15