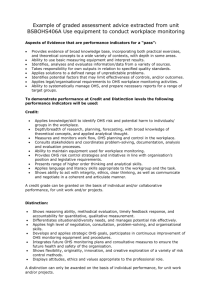

SAT - detailed response_blank

advertisement

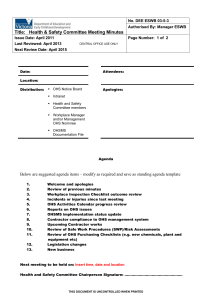

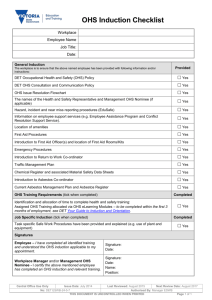

SAT TOOL – School response Document number: [Insert local area document number] Prepared on: [INSERT DATE] Submitted on-line on: [INSERT DATE] Issue # 000[INSERT NUMBER] Discussed at L3 H&S consultation committee on: [INSERT DATE] # Crit No. 1. 1.1.2 2. 2.1.3 3. 2.1.1 4. 2.1.5 5. 2.2.1 Examples of evidence Audit Question Is the UNSW OHS Policy displayed in a prominent position in the workplace? Do relevant people have ready access to current OHS legislation and standards? An electronic copy of policy is on OHS Unit website Policy included in induction material Policy included in tender documentation (ie. communication to contractors) Policy is displayed in reception/visitor areas Access to legislation under “Web Links” on the OHS Unit website Is there a mechanism to communicate changes to legislation, standards and University procedures to relevant people? OHS Committee Reps receive monthly OHS Coordinator’s report OHS Committee meeting minutes Emails Does notification of changes to legislation or standards prompt a review of relevant risk assessments/protocols/safe work procedures? Are you aware of any health and safety targets and objectives set by UNSW Level 1 OHS committee? Reviewed risk assessments/Safe Work Procedures (SWPs) Emails Page 1 of 23 Current OHS Strategic Plan UNSW OHS Measures and KPTs for Managers L2 OHS Committee minutes Response evidence Corrective Action Required # Crit No. 6. 2.2.2 7. 2.2.3 & 2.3.3 & 3.6.4 8. 3.1.1 &3.1. 2 9. 3.1.3 10. T 3.2.1 r a Examples of evidence Audit Question Does the Faculty document OHS objectives, or is OHS included in key performance targets for senior managers (e.g. Head of School/Dept)? Are there tools/mechanisms in place for monitoring progress towards meeting the OHS objectives and targets in your work area? Faculty/Division operational plans include OHS objectives Senior Managers have OHS objectives included in their KPTs Have financial and physical resources been identified, allocated and periodically reviewed, to enable the effective implementation of UNSW’s health and safety management system? Budget provided for OHS Budget to allow risks to be controlled by engineering means Funding to allow equipment to be upgraded/replaced as required Competent personnel allocated to ensure implementation of system e.g. Staff to provide training on equipment, maintain OHS documentation, OHS Reps. OHS Reps are allocated time to: Are OHS representatives (committee members) provided with time and resources to effectively undertake this role? Can senior management demonstrate an understanding of UNSW’s legal obligations for Page 2 of 23 Quarterly review of OHS statistics at OHS Committee meetings, including for example: % of staff who have completed OHS induction % of staff who have completed OHS awareness training % of corrective actions closed Injury statistics Completion of Self Audit Tool (SAT) by local area annually attend OHS training, prepare for & attend OHS meetings, conduct workplace inspections, attend incident investigations Head of School/Department Manager has attended OHS Due Diligence or OHS for Supervisors Response evidence Corrective Action Required i n 11. 3.2.3 PI 12. Examples of evidence Crit No. # 3.2.5 Audit Question health and safety? E.g. Attendance at Due Diligence or OHS for Supervisors training? Have OHS responsibilities been assigned and communicated to all staff? E.g. Maintaining registers, closing corrective actions, training, inspection and testing of equipment, keeping records. Is OHS performance included in staff performance reviews? PI 13. c 3.2.4 o n t r a c t o r s 14. 3.2.4 training OHS responsibilities may be included in: Position descriptions OHS 336 Responsibility Procedure Laboratory Manuals Performance Development Scheme (PDS) If OHS tasks have been assigned, the completion of such tasks are monitored through the annual performance appraisal conducted by the supervisor or other mechanisms e.g. Monthly meetings Does your area engage contractors directly? (i.e. not via Facilities Management) NOTE: If they answer “NO” then they do not need to complete Qs 14, 15 & 16. Where contractors are engaged, are the OHS responsibilities for both the contractor and the University clearly defined, allocated and Page 3 of 23 Documented OHS responsibilities for both parties e.g. contractual agreements Induction program for contractors covering responsibilities and Response evidence Corrective Action Required # Examples of evidence Crit No. Audit Question communicated? accountabilities Checks include evidence of: - Workers Compensation insurance - Public liability insurance Is an assessment conducted of the ability of contractors to meet health and safety requirements prior to engaging the contractor? 15. 3.10.3 16. 3.10.4 17. 3.5.3 18. 3.2.4 Is an OHS Induction provided to all contractors? Assessment is conducted for UNSW preferred suppliers Health & safety requirements (including evidence of workers compensation and public liability insurance) are stated in contractual documents, where local area engages contractor Periodic audits are conducted Progress meetings with contractor include OHS issues Records of observation of contractor performance (e.g. Diary entries) Correspondence with contractors about issues of non-compliance OHS induction for contractors/visitors Minutes of meetings with contractor, suppliers, authorities etc which record discussion of OHS issues Equipment manuals from suppliers Safety Data Sheets for any chemical used by contractors Completed contractor induction checklists for local area 19. 3.4.2 Has the work area determined the number of employee OHS634 OHS Committee Constitution document has been Is contractor health and safety performance monitored and reviewed to ensure continued adherence to UNSW health and safety requirements or specifications? Is relevant health and safety information exchanged between local area and external parties including customers, suppliers, contractors and relevant public authorities? Page 4 of 23 Response evidence Corrective Action Required # Examples of evidence Crit No. 20. 3.4.3 21. 3.3.9 22. 3.4.4 23. 3.4.6 24. 3.9.7 Audit Question representatives required to effectively represent all employee work groups? completed and is up to date Minutes of meetings that record discussion regarding appropriate number of employee vs employer reps Are employees involved in the selection process for their OHS representatives? Examples may include: Emails requesting nominations for OHS Reps Minutes of OHS Committee meetings Have all OHS Reps. and members of OHS committees received OHS consultation training? Have the names and identities of the work area’s employee and employer OHS representatives been communicated to all staff? Records of attendance at OHS Consultation training Does staff get informed about changes to their work processes and environment so they can be consulted on the OHS risks of such changes, if applicable? Committee minutes Staff meetings Emails Are risk assessments undertaken for changes in the workplace which may affect health and safety (if applicable)? Completed risk assessments if local area has undergone change in the workplace Page 5 of 23 Emails Committee minutes Local area website Response evidence Corrective Action Required # Examples of evidence Crit No. 25. 3.4.7 26. 3.4.7 27. 3.5.2 28. 3.3.8 PI 29. 3.6.1 30. 3.7.1 PI Audit Question Are OHS Committee meetings held at least quarterly? L3 OHS Committee constitution which specifies frequency of meetings OHS Committee meeting minutes Are minutes of OHS meetings made available to all personnel? Minutes of OHS Committee meetings are distributed via email and/or posted on staff noticeboards Minutes posted on local area website Is there a feedback mechanism to report progress on OHS issues (or resolution of OHS disputes)? Online hazard & incident reporting system Emails Minutes from OHS Committee meetings Have all supervisors and managers completed “OHS for supervisors” training? Training attendance records Are staff notified about the procedure for reporting hazards and incidents in the workplace? OHS Induction records which document that Hazard & Incident reporting procedure is covered during Induction Links to the OHS website is included on local area website Are local OHS procedures (e.g. SWPs) easily identifiable, accessible and included on a documents register? Document control is included on local procedures including SWPs Local procedures are available on school/unit website Completed OHS document register Page 6 of 23 Response evidence Corrective Action Required # 31. 3.8.1 &3.8. 2 32. 3.8.3 PI 33. Examples of evidence Crit No. 3.8.4 PI 34. 3.10.2 35. 3.10.5 PI Audit Question Is there a system for creating, modifying and approving local area health and safety documents, and notifying relevant persons of any changes? Are health and safety documents readily accessible to users? Do local OHS documents get reviewed by competent persons to ensure the adequacy and currency of the information? Are health and safety requirements documented and incorporated into purchasing specifications for services? Are health and safety requirements considered prior to the purchase of goods? e.g. impact on the workplace, additional training requirements etc. Page 7 of 23 Examples of local area procedures Examples of updated versions of procedures following review, including version number and review date Emails to staff notifying them of new/revised OHS procedures University OHS procedures are available on UNSW OHS website Local OHS documents are available on school/unit website or in hard copy within local area Local OHS documents including risk assessments and SWPs are reviewed and signed off by appropriate and competent Supervisor UNSW preferred suppliers are used Staff follow UNSW Tender Procedure for purchases where “no UNSW preferred supplier” exists Local area has evidence that OHS requirements are communicated to the contractor prior to engagement Completed OHS0633 Pre/Post Purchasing Checklist Response evidence Corrective Action Required # 36. 3.10.6 PI 37. 3.11.8 38. 2.3.2 39. 3.9.1 & 3.9.3 PI 40. 3.9.1 PI 41. 3.9.2 PI 42. Examples of evidence Crit No. 3.9.4 & 2.1.2 Audit Question Are purchased goods checked for compliance with specifications prior to being put into use? Have all staff been informed about the Employee Assistance Program (EAP) for dealing with exposure to critical incidents at work? Does the local area follow the UNSW procedures for conducting risk assessments? Has your local area systematically identified and documented its hazards and risks and implemented control measures according to the hierarchy of risk control? Do risk assessments take into account the risks involved in working after hours and/or working alone? Completed OHS0633 Pre/Post Purchasing Checklist EAP Information included in HR Induction EAP info included on local area website EAP phone number displayed on staff noticeboards Completed risk assessments Completion of online hazard and incident reports Local area Hazard & Risk Register Completed risk assessments for tasks/ projects/activities that pose OHS risks including work with chemicals, biological or infectious materials, radiation devices /radioactive substances, manual handling tasks, plant and equipment etc. Risks involved in working after hours and/or working alone are included in Risk Assessments and Hazard & Risk Register Have all personnel who undertake risk assessment completed OHS Awareness training or equivalent? Training attendance records Do risk assessments take into account legal requirements or any other available information, past incidents, Completed risk assessments showing reference to relevant legislation, standards or codes of practice Page 8 of 23 Response evidence Corrective Action Required # PI 43. 3.9.5 PI 44. Examples of evidence Crit No. 3.7.2 PI 45. 3.10.1 46. OUR S Audit Question and potential for emergency situations? Is the timing of corrective actions done in accordance with the timeframes set for the risk rating? Action to be taken in the event of an emergency addressed in risk assessment Corrective action is completed within timeframes set by risk rating from the online reporting system Have safe work procedures been developed to address specific risks? (e.g. hazardous substances, biological hazards, radioactive substances etc) Completed Safe Work Procedures for tasks/ projects/activities that pose OHS risks including work with chemicals, biological or infectious materials, radiation devices /radioactive substances, manual handling tasks, plant and equipment etc. Have those areas where access control is required, been documented and are procedures in place to enforce access requirements? Are ergonomic workstation assessments (peer or self assessments) carried out for office based staff? Swipe card access Authorised key holders Documented procedures for access Is appropriate manual handling equipment available where required, and have staff been trained in its use? Completed manual handling risk assessments identify the need for manual handling equipment Visual assessment of equipment Is a risk assessment undertaken during equipment or building modification, Completed risk assessments Evidence that health & safety considerations are examined Completed workstation assessment checklists PI 47. OUR S PI 48. 3.10.7 Page 9 of 23 Response evidence Corrective Action Required # Examples of evidence Crit No. Audit Question refurbishment or design? 49. 3.10.8 50. 3.10.9 PI 51. 3.10.1 1 PI 52. 3.10.1 2 PI 53. 3.10.1 3 prior to installation of new equipment Are competent personnel involved in verifying that the designs and modifications to equipment meet specified health and safety requirements? Are all hazardous materials and substances disposed of in accordance with OHS321 Hazardous Waste Disposal Guideline? (E.g. chemical, biological, animal carcass, decayed radioactive waste etc). Are there safe work procedures for the handling, transfer and transport of hazardous substances and dangerous goods? Evidence that competent people have involved in the designs and modifications to equipment e.g. relevant licences or accreditation etc. Is comprehensive health and safety information on all hazardous substances and dangerous goods readily accessible? Access to UNSW OHS website Compliant labels on all containers Access to ChemAlert Safety Data Sheets are available Are hazardous substances and dangerous goods safely stored according to the Safety Data Sheet? Compliant dangerous goods storage facilities Self audits of chemical storage Compliant chemical labelling If applicable, are there ‘Permit to Work’ procedures for highrisk tasks e.g. confined space Completed permits Completed waste request forms Review of waste storage facilities Completed SWPs are available PI 54. 3.10.1 4 Page 10 of 23 Response evidence Corrective Action Required # Examples of evidence Crit No. Audit Question or hot work? 55. 3.10.1 7 Are staff aware of the process to remove/quarantine unsafe plant and equipment? Examples of equipment being “locked out” with “danger tags” or “out of service tag” in use. Laboratory induction Are appropriate controls used to ensure the safety of persons working on or near plant and equipment that is in the process of being cleaned, serviced, repaired or altered? Isolation and lockout requirements in OHS327 Plant and Equipment Procedure is followed for maintenance or cleaning activities where deenergising is required Evidence of completed “Out of service” or “Danger” tags that have been used on equipment Service records show competent person checks that plant is safe to use after repairs or maintenance PI 56. 3.10.1 8 PI 57. 3.10.1 9 58. 3.10.2 1 59. 3.10.2 5 Do competent personnel verify that plant and equipment is safe to use before being returned to service after repair or alteration? If applicable, are there procedures to ensure that materials are transported, handled and stored in a safe manner? (NOTE: This relates to general storeroom/warehouse facilities as opposed to dangerous goods storage) Do samples and materials provided for diagnostic or testing purposes undergo risk assessment prior to use? PI Page 11 of 23 Local area is following OHS709 Materials Handling Guideline if applicable Safe Work Procedures are available if required Procedures are in place to protect persons receiving or working on samples or materials that are provided for diagnostic or testing purposes Response evidence Corrective Action Required # Examples of evidence Crit No. 60. 3.10.2 6 61. 3.11.6 PI 62. 3.11.6 63. OUR S 64. 2.1.4 PI Audit Question Are all substances in containers and transfer systems identified and clearly labelled to avoid inadvertent or inappropriate use? Is a chemical register available that includes details of all dangerous goods and hazardous substances present in the workplace? If applicable, are your dangerous goods storage areas included in the dangerous goods manifest for your building? Is the management of your specific hazards being monitored against the relevant systems audit checklist e.g. chemical system audit checklist, bio-safety audit checklist etc. If applicable, does the work area satisfy legal requirements to undertake specific activities, perform work or operate equipment including: (a) Any licence required?– e.g. Licences or approvals for certain processes such as asbestos removal, use of carcinogens, radioactive sources and lead; (b) Any Certificate of competency required? (c) Is notification to a Page 12 of 23 Substances are properly labelled according to OHS429 Labelling of Hazardous Substances Up to date chemical register is in place Completed dangerous goods manifest as per OHS333 Dangerous Goods Placard & Manifest Procedure Completed audits/checklists for Biological hazards, Chemical Hazards, radiation. Radiation users licence Forklift licence AQIS approved premises Workcover approval for prohibited or notifiable carcinogens PC2 certification for laboratories working with genetically modified organisms Response evidence Corrective Action Required # 3.3 65. 3.3.1 PI 66. Examples of evidence Crit No. 3.3.2 PI Audit Question regulator required? (d) Is registration of equipment/premises required? (e.g. radiation or AQIS premises)? (e) Is there approval, exemption requirements? Training and Competency Have jobs which require the incumbent to have specific skills/competencies and/or specific medical requirements to perform that job safely been identified? Have these requirements been included in job descriptions and job ads? Pre-employment health screening is conducted for staff working with animals Job ads specify licence or certification requirements if applicable e.g. Electrician or forklift operator Job descriptions identify specific skills/competencies or specific medical requirements that are required to perform the job safely Has the training needs of staff (visitor & contractors as relevant) been identified according to the work they will be doing, location of the work, previous training and competency e.g. general OHS awareness, work with infectious materials, chemicals, radiation, ergonomic, manual handling etc. Generic Training needs are identified as per OHS 320 OHS Training and Induction procedure, including Table 1 and 2 for mandatory OHS training required to satisfy certain competencies Local training needs analysis identifies competencies to operate pieces of equipment Evidence that staff have been trained & are competent in SWPs for equipment Page 13 of 23 Response evidence Corrective Action Required # 67. 3.3.3 PI 68. 3.3.5 PI 69. 3.3.6 PI 70. Examples of evidence Crit No. 3.3.7 Audit Question Are all personnel appropriately inducted into the workplace according to their level of risk exposure? Completed inductions After staff, contractors and labour hire employees have completed training, does the work area assess the individual’s ability to apply the knowledge/skills learnt during the training, in order to perform the job safely? (ie. Competency based training) Training records Training assessment/test after completing training courses Training in an SWP with demonstrated ability that it can be followed accurately.(e.g. checklist) Is training and assessment delivered by persons with appropriate knowledge, skills and experience? Local training is delivered by competent people as identified on the SWP Are tasks allocated to match the skills, training and capabilities of employees? Evidence that job application addresses the selection criteria in the job advertisement Competency to perform specific tasks is confirmed before allocation of tasks Is OHS refresher training undertaken as required? Training plan includes provision for refresher training The nominal refresher period identified in UNSW’s OHS320 OHS Training Procedure are used as a guide Evidence that training materials are reviewed and updated PI 71. 3.3.10 PI 72. 3.3.11 PI Is the training provided by the local area reviewed on a regular basis, and when there are changes to plant or processes in the workplace? Page 14 of 23 Response evidence Corrective Action Required # 73. 3.10.1 0 74. 3.10.1 5 PI 75. 3.10.2 0 76. 3.10.2 2 PI 77. Examples of evidence Crit No. 3.10.2 3 Audit Question Are facilities and amenities checked against the requirements of relevant legislation, standards and codes of practice? Completed Workplace Inspections Is the Personal Protective Equipment (PPE) provided appropriate for the task, are people trained in its use, is it used correctly and is it maintained in a serviceable condition? Safe Work Procedures specify any relevant PPE that must be worn Observations of staff using PPE during workplace inspections Do safety signs meet relevant standards and are they appropriately displayed? Safety signs conform with OHS732 Signage Guideline Are individuals supervised according to their capabilities and the degree of risk of the task? SWP’s specify the level of supervision required Are supervisors monitoring that tasks are performed safely and work instructions and procedures are followed? Local organisational charts showing reporting lines Completed OHS729 Laboratory Review Forms Training records for attendance at OHS for Supervisors course Performance appraisals for Supervisors Potential emergencies within local area have been identified If required, local site procedures have been developed to identify actions to be taken for specific emergencies e.g. isolating a gas valve before evacuation or PI 78. 3.11.1 Have potential emergency situations been identified and emergency procedures documented and regularly reviewed? Page 15 of 23 Response evidence Corrective Action Required # Examples of evidence Crit No. Audit Question shutting off heat or ignition sources. 79. 3.11.2 & 3.11.7 80. 3.11.3 81. 3.11.4 82. 3.11.4 Has the area allocated responsibility for control of emergency situations (including appropriate number of First Aid Officers) to specified individuals and communicated this information to all personnel? Documented assessment of Emergency personnel needs with respect to numbers and size of work area, risk level, proximity to hospital or UNSW health service etc. Have emergency response personnel received appropriate training for their duties? Have competent persons assessed the suitability, location and accessibility of emergency equipment that is not being centrally maintained by Facilities? (e.g. First Aid Kits, Spill Kits, Emergency showers) Training records Are the following emergency resources available as applicable? First Aid Kits Spill kits capable of First Aid Kits are easily accessible to staff Spill kits are available, with appropriate contents to match the needs of the area Page 16 of 23 A documented emergency plan with details of responsibilities for Fire Wardens, Emergency Controllers and First Aid Officers Induction process that includes introducing employees to local fire wardens etc. Training records for attendance at First Aid/Fire Warden training Spill kits are available, with appropriate contents to match the needs of the area Checks that emergency showers and/or eyewash stations are operating and maintained Response evidence Corrective Action Required # 83. 3.6.3 84. 3.6.5 85. 3.10.1 6 PI 86. Examples of evidence Crit No. 3.10.1 6 Audit Question being able to handle the largest size containers Suitable PPE in the spill kit such as reusable gloves, goggles, respirators and cartridges, gum boots etc as appropriate Are inspection, testing and monitoring reports communicated to Head of School/Work Unit (and committee representatives)? Are OHS audit reports distributed within your area? Is there a local inspection, testing and monitoring schedule for plant and equipment and maintenance records kept? Is electrical testing & tagging conducted in the local area at the required frequency based on the risk? Page 17 of 23 Committee minutes table outcomes of workplace inspections/electrical testing & tagging reports etc., where Head of School/Unit (or their nominated representative) is present Minutes of meeting reflect that progress of corrective actions is monitored Email distribution of audit reports Audit report findings communicated at OHS Committee meetings Completed Plant Register/ Inspection, Testing and Monitor schedule Maintenance records Electrical testing & tagging records Current tags on equipment Response evidence Corrective Action Required # 87. 4.1.1 88. 4.1.1 89. 4.1.2 90. 4.1.3 PI 91. Examples of evidence Crit No. 4.1.4 Audit Question Do local area workplace inspections occur using appropriate checklists? Completed workplace inspection checklists Records of other workplace inspections e.g. PC2 inspections, Chemical audit. Completed lab/workshop review forms to monitor conformance with SWP and measure effectiveness of risk controls Are corrective actions identified during workplace inspections added to online corrective actions register through myUNSW? Do inspections require the involvement of personnel in the area being inspected? Are engineering controls, including safety devices, regularly inspected and tested to ensure their integrity? Corrective actions arising from inspections are entered into online reporting system Is monitoring of the workplace environment (general and personal for fumes, dust, noise, radiation, etc.) conducted where appropriate and records of the results maintained? Page 18 of 23 Verbal verification Plant is inspected in accordance with Inspection, Testing & Monitoring Schedule Maintenance records confirm inspection of engineering controls e.g. fixed guards & barriers, emergency stop buttons Local area is familiar with OHS091 Air Monitoring and Health Surveillance Guideline Risk Assessments that identify the need for workplace monitoring for hazards such as noise, fumes, gases, radiation, are available Records of air monitoring (including radiation swipe tests) are available, if applicable Response evidence Corrective Action Required # 92. 4.1.5 PI 93. 4.2.1 PI 94. Examples of evidence Crit No. 4.3.1 Audit Question Is inspection, measuring and test equipment used for health and safety monitoring appropriately identified, calibrated, maintained and stored? Has the area identified those situations where employee health surveillance should occur and is a system implemented to conduct this surveillance? Records of calibration of equipment Records of scheduled maintenance Are supervisors involved in incident investigations? OHS307 Hazard and Incident Reporting Procedure is followed Online hazard & incident form has been completed, including corrective actions OHS003 Incident Investigation Guide is followed Completed investigation documents which show the involvement of line managers in the process Interview notes from interviews conducted with line managers Emails from line managers Are personnel identified to implement and review corrective actions arising from investigations? Are corrective actions discussed with personnel Corrective Actions register on online system Identified in Investigation report & 4.3.2 95. 4.3.3 96. 4.3.4 Page 19 of 23 Risk assessments/incident reports identify those situations where employee health surveillance is required Results of radiation personal dose monitors Results of eye examinations for exposure to lasers Results of audiometric testing if required Verbal verification Response evidence Corrective Action Required # Examples of evidence Crit No. 97. 4.4.1 98. 4.5.3 99. OUR S Audit Question affected prior to implementation? Are there effective systems in place for the management of OHS records including where they are stored, who has access, what’s confidential, how long they are maintained, how they will be disposed etc ? Are non-conformances identified during an OHS audit prioritised and progressed until action has been completed? SPECIFIC QUESTIONS RELATING TO BIOLOGICAL AND RADIATION HAZARDS: Is your work unit involved in any activity that poses a biological risk? If ‘No’ go to question 104. Completed current local OHS Records register in accordance with OHS 733 Records Procedure Non-conformances have been entered and are tracked in corrective actions register n/a PI 100. OUR S PI 101. OUR S PI 102. OUR S PI Are you maintaining a Biological Organisms Register? Completed biological organisms register using OHS075 Biological Organisms template. If applicable, is your PC2 containment facility registered using the School containment facility register? All PC2 containment facilities are included on the OHS 078 Containment Facility register. If applicable, is the location where gene technology work occurs monitored to ensure it meets with the Gene Technology Regulations and has it being certified if required? Annual inspections by the IBC Other completed inspections by supervisors or OHS committee Page 20 of 23 Response evidence Corrective Action Required # Examples of evidence Crit No. 103. OUR S Audit Question Are all dealing with genetically modified organisms assessed by UNSW IBC or the OGTR as per Bio-safety Procedure? Completed records of research projects having been assessed by the IBC using OHS013 GMO application form Has a Radiation Safety Supervisor and TLD Badge Coordinator been nominated to facilitate communication on radiation safety issues and assist with implementation of the Radiation Safety Procedures? The role of Radiation safety supervisor has been allocated in the local area and responsibilities documented. Is a purchasing procedure for the purchase of radioactive isotopes implemented to avoid the need for long term storage of radiation waste? Purchasing for radioactive isotopes is screened as per local area purchasing system. Are all staff using ionising radiation who need licensing appropriately licensed? Records show that all staff who work with radioactive substances or radiation devices are licensed. Are licence exemption procedures in place for students? Evidence that students are working under supervisor’s licence. Are all projects involving radiation approved by the UNSW Radiation Safety Committee? Completed OHS695 Project/Program Approval Forms for radiation work . PI 104. OUR S PI 105. OUR S PI 106. OUR S PI 107. OUR S PI 108. OUR S PI Page 21 of 23 Response evidence Corrective Action Required # Examples of evidence Crit No. 109. OUR S Audit Question Is all radiation waste requiring storage adequately labelled and stored in an appropriate location? Physical evidence – labels on containers, evidence of waste transfer to radiation store. Are all laboratories (premises) using unsealed radioactive materials exceeding prescribed limits registered? Laboratories using licensable quantities of unsealed radioactive materials are registered. PI 110. OUR S PI Page 22 of 23 Response evidence Corrective Action Required ACTION SHEET Q. Issue # SAT question number Issue number generat ed by online hazard reportin g system Action Corrective actions Page 23 of 23 By Who Date done