display

advertisement

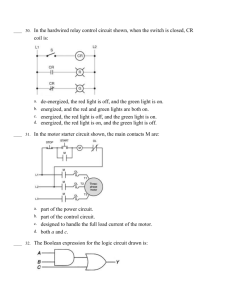

Change of Resistance Test Stand PROJECT MEMBERS: COLIN PAYNE-ROGERS JACOB LENNOX PROJECT GUIDE/MENTOR: DR. BENJAMIN VARELA PRIMARY CUSTOMER: JOE MANAHAN SPONSOR: COOPER CROUSE-HINDS Project Description Project Goal: To Design/Build a prototype test stand to measure the temperature of a maximum of 6 coils using a linear regression 4-wire resistance method. Project Overview: The test stand will include but is not limited to a cart/apparatus, laptop with LabView, data acquisition hardware, control circuitry and switching hardware, power dissipation circuitry and hardware. The apparatus is intended to use LabView to allow the user to run the test with minimal intervention. The prototype will be tested at RIT at 120VAC due to safety concerns. Project Description Customer Specifications Design and Build a Relay Circuit Operation: 120-480VAC, 50-60Hz Amphenol cable or similar connection Controls electrical power for the operation Select and Purchase a Digital Multimeter Resolution: 0.01Ohms Able to be calibrated Select and Purchase a Data Acquisition System Additional temperature measurement using thermocouple Customer Specifications Write a LabView program for the test stand Communicate with and control measurement hardware Measure the resistance of a maximum of 6 coils 40 readings every 30 seconds (one reading at a time) Operator flexibility on coil selection (for measurements) Plot Resistance versus Time for each coil Make a Linear Regression of the data to calculate the temperature of the data at the beginning of the test Store the data in up to 9 different portable format files Operator input: time, date, coil material Selectable functions: pre-run test, run auto-test, view results, print results, terminate All of the components must be contained in a rolling enclosure Test Stand must comply with UL 844 Meeting Priorities Proof-of-Concept Experimental Design Experimental results Proposed prototype relay circuit design Bill of Materials Test Plan Inquire about laptop and LabView licensing Experimental Circuit Design Experimental Circuit Design Experimental Circuit Design Experimental Results Coil 1 Resistance (Ω) Direct-toBallast Through Relay Circuit Coil 2 Resistance (Ω) 3.798 2.678 3.801 2.677 RIT Cooper Rc from DMM Rc (Ω) not from DMM 4.1 3.66 Th (°C) 51.75 86.52 Rh (Ω) 4.57 4.57 Rc (Ω) 3.801 3.361 Th (°C) 55.92 93.94 Rh (Ω) 4.3037 4.3037 Experimental Results Relay Circuit Design Bill of Materials Accessory PXI Chassis Chassis Power Cord DMM Relay Module Relay Terminal Block System Assurance Power Circuit Relay Power Circuit Relay USB DAQ Circuit Total Labtop Labview Lisence Miscellaneous Vendor NI NI NI NI NI NI PN 781162-01 763000-01 780011-01 778572-66 778717-66 960903-02 Description Indv. Cost NI PXIe-1073 $ 1,499.00 $ 9.00 NI PXI-4065 $ 1,499.00 NI PXI-2566 $ 1,080.00 TB-2666 $ 277.00 $ 310.00 McMaster Carr Allied Elec NI 7230K91 70198625 779051-01 4PST DPST USB-6008 NI *Highlighted Boxes are approximate costs Cart etc. $ $ $ QTY Cost 1 $ 1,499.00 1 $ 9.00 1 $ 1,499.00 1 $ 1,080.00 1 $ 277.00 1 $ 310.00 76.91 10.07 169.00 4 1 1 $ 500.00 $ 999.00 $ 1,000.00 1 1 1 Total $ 307.64 $ 10.07 $ 169.00 $ 5,160.71 $ 500.00 $ 999.00 $ 1,000.00 $ 7,659.71 Test Plan Number Description 1 Test the ballast temperature/resistance measurements with a borrowed 4-wire multimeter but the updated relay circuit (using "final hardware" and one coil rather than "experimental hardware"). Show the exponential decay, and the difference in resistance measurements when measuring the ballast directly and through the circuit. 2 Test the ability to switch between different coil measurements using the NI switch, manually and automatically, and then verify the results from test #1 for the same coil when switching to the other coils inbetween each measurement (possibly taking all coil measurements)...with the borrowed multimeter still? 3 Show that initial measurements are capable of being taken within 5 seconds, and that all 6 coil measurements are capable of being taken at the required rate. This would be a final "proof-of-concept" test, showing that the LabView program can be used to measure 6 coils as quickly as needed and can spit out the correct data (data compared to #1). The NI multimeter used this time to show that it is calibrated as well as the borrowed multimeter. 4 Test the calibration routine by using a "correct" and "incorrect" calibration. The "correct" calibration for the calibration routine should give the correct ballast (room temperature) results while the "incorrect" calibration should offset the ballast resistance measurements? This test depends on the final method for calibration. Timeline Task Completed By Select and Purchase Hardware End of Week 11 of MSD I First version of LabView Code Completed (using simulated hardware) End of Week 2 of MSD II CAD Models (cart design) End of Week 3 of MSD II Order Cart Hardware End of Week 4 of MSD II Complete Testing with NI Hardware (not on cart) End of Week 6 of MSD II Assembled Electronics End of Week 7 of MSD II Complete any other testing at RIT (120 VAC, with cart, full tests with LabView) End of Week 8 of MSD II End of Week 9 of MSD II Finalize Senior Design Requirements End of Week 10 of MSD II