DSSC and TF Poly

advertisement

DSSC and TF Poly-Si

Solar Cells

Dye-sensitized TiO2 and thin film polysilicon solar cells: fabrication and

measurements of photon-to-electron

conversion efficiencies using LabView

National Nano Device Laboratory

Tainan Science Park

Taiwan Tech Trek (TTT) 2006 Interns:

Eric Chang

Department of Electrical Engineering and Computer Sciences

University of California at Berkeley

Kevin Chen Ying Chang

Department of Electrical and Computer Engineering

University of California at San Diego

Yu-Kai (Kevin) Su

Department of Biomedical Engineering

Washington University in St. Louis

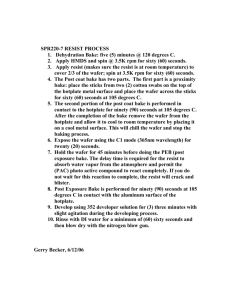

The Clean Room

Different levels - NDL

Tainan is level 10,000 per

cubic feet

Requires standard

uniforms

For our clean room, we

have to have specialized

hats, gloves, jackets,

shoes, and mouth covers

Temperature, pressure,

and humidity are

constantly monitored so

room condition can be

kept at an optimal level

Standard Lab Clothing

The Equipments and Technology

Wet bench

Consists of four different

chemical solutions to eliminate

extra foreign particles

PECVD (Plasma Enhanced)

- produces organic thin film

by growing silicon

dioxide/poly-silicon

Furnace is LPCVD (Low

Pressure) – same function

as PECVD requiring longer

time for processing but better

quality

Wet Bench

The Equipments and Technology

(Continued)

Photolithography

Includes following

processes in order: priming,

putting on photo resist (PR),

pre-baking, UV exposure

with mask, and then hard

bake

Exposure - uses a mask to

allow entrance of UV light to

hit target wafer, which causes

chemical reaction with the PR

Area uses yellow light so PR

is not damaged

Photolithography

The Equipments and Technology

(Continued)

PR spin coated onto wafer

(manually or automatically)

Track (automatic) –

Can perform all steps

necessary for coating the

wafer using an automated

computer system

Spin Coater (manual)

Choose desired size of target

Manually test optimal

parameters

(RPM/time/position)

Spin Coater

Spin Coating

Main purpose: to achieve an even surface

Side View of an Uneven Surface

slide

Side View of an Even Surface

slide

Spin Coating Demonstration

The Equipments and Technology

(Continued)

Thermal Evaporator and

Sputter - both coat thin film

of metal on the target wafer

Thermal evaporator –

evaporated metal on

bottom hits wafer on top,

then molten metal

gradually spreads evenly

from center of wafer to coat

surface

Sputter – molten metal on

top rains down droplets at

numerous positions to coat

the wafer on the bottom

Sputter

The Equipments and Technology

(Continued)

The ICP and RIE are

both machines that

are used for etching

ICP is better since it

can etch out the whole

target wafer while the

RIE cannot

Etchant is very

corrosive and

dangerous, so

protective gear is

required

Protective Mask

The Equipments and Technology

(Continued)

AFM – scans out 3D image of target’s surface

Nano-scale probe vibrates with a certain frequency

at a synchronized distance away from the target

Vibration changes can be detected by a light that is

reflected upon it, which gives data for image

Probe station

Uses microscope and nano-scale probe to make

contact with different shapes of arrays on target

Probe station is utilized for contact with

conductive materials, while AFM targets regular

surfaces

The Mask

The design and pattern

of the mask developed through

AutoCad, then sent to

specific company for

production

Normal mask is created

with glass and

Chromium (1-2 months

for completion)

Due to limited time,

replaced the materials

with plastic and chalk,

(only an overnight

process)

Masks

Mask Aligning

Some Measuring Equipments

Some Measuring Equipments

Finding the Optimal RPM and Time

0.2 mL HAc (hydrogen acetate) in 100 mL DI water

TiO2: 1.35±0.05 g with 40 drops of acetic acid

RPM

1

2

3

4

500

1300

1200

1100

30

30

30

Time (second) 20

Table 1: 70 Drops of Acetic Acid

RPM

Time (second) Comment

7A

1100

30

7B

1100

30

7C

1000

30

7D

900

30

not drops, painted on (corners)

7E

900

30

Less TiO2 at the corners compared to D

7F

1100

30

Less drops, not as evenly distributed

7G

1100

30

7H

1100

30

More drops at corners

Table 2: 80 Drops of Acetic Acid

RPM

Time (second)

8A

1000

30

8B

900

30

8C

700

20

8D

800

10

8E

700

40

Comment

Not evenly spread

Surfactant

Triton X 100

Surfactant

Table 3:

2 g TIO2 {60, 70, 80} drops Triton X 100 (surfactant)

RPM

Time (second)

Comment

7XA

900

30

Good, with little bubbles

6XA

1100

30

Thicker than 7A, more bubbles

6XB

1200

30

7XB

900

30

7XC

800

30

8VC

700

30

Fabrication of DSSC

Upper Electrode (1)

Spin-coating

PR: AZ 5214

Step 1: 500 RPM for 5 s

Step 2: 3000 RPM for 30 s

Soft bake

90°C, 30 s

Exposure

Plastic mask of our design

Duration: 4 s

Fabrication of DSSC

Upper Electrode (2)

Reverse Bake

110°C, 120 s

Reverse, flood Exposure (without mask)

15 s

Develop

AZ 300 developer for about 30 s

Hard Bake

100°C, 60 s

In order to make the photoresist negative:

REVERSE BAKE

AND

REVERSE FLOOD EXPOSURE

Fabrication of DSSC

Spacers

Spin-coating

PR: Su8

Step 1: 500 RPM for 5 s

Step 2: 3000 RPM for 30 s

Soft bake

90°C, 30 s

Exposure

Plastic mask of our design

Duration: 15 s

Fabrication of DSSC

Spacers

No reverse bake or reverse

flood exposure

Develop

AZ 300 developer for about 30 s

Hard Bake

100°C, 60 s

Fabrication of DSSC

Final steps to putting together our DSSC cell:

Put on

electrolytes

Place the ITO glass carefully

on top of the side with the

electrolytes

Hold the ITO glass in place

with something

DSSC

How It Works and How to Test It

Electron Transfer Process

injection

regeneration

recapture

hopping

Studying Photovoltaic Performance

4. gold electrode

3. dye-sensitized

heterojunction

2. compact

TiO2 layer

1. conducting F-doped

SnO2-coated glass

Avoids direct contact

between the HTM layer

and the SnO2, which

would cause short circuit

Thin-Film Poly-Silicon

0C

0

Anneal

Induce

crystal:

at 500

500

for

Remove

Amorphous

Al layer

Si 1hr

by wet etching

a-Si 4750nm

poly-Si 5000nm

Amorphous Si

Induced metal layer

Bottom electrode

Al 250nm

a-Si

Al 250nm

poly-Si

250nm

ITO 300nm

Glass

Closeup

A Detailed Look at Our

Experiments

Photoresist Remains

50x

200x

100x

600x

TiO2

50x

100x

good contact

TIO2

]

electrode

200x

LabVIEW Portion

Measurements & Results

LabVIEW Portion

LabVIEW Portion

LabVIEW Portion

VM

4

3.5

Voltage

3

2.5

2

1.5

1

0.5

0

0

0.5

1

1.5

2

2.5

Time

3

3.5

4

4.5

LabVIEW Portion

I1

3.00E-03

2.50E-03

Current

2.00E-03

1.50E-03

1.00E-03

5.00E-04

0.00E+00

-5.00E-04

0

0.5

1

1.5

2

2.5

Time

3

3.5

4

4.5

The END