The Space Shuttle Challenger Disaster is an incident that still

advertisement

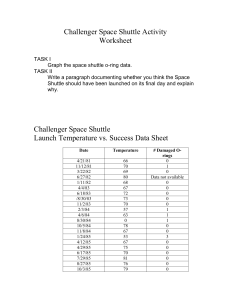

PENNSYLVANIA STATE UNIVERSITY Space Shuttle Challenger Disaster Historic Decision Paper Henry Sykes 11/14/2013 Sykes 1 Table of Contents BLUF…………………………………………………………..…………………….………….2 Background……………………………………………….…….………………………...…….2 Key Decision……………………………………………………………………………………2-4 Lessons Learned…………………….…………………………………………………………4-6 Personal Lessons Learned…………………………...………………………………………..6 Work Cited……………………….…………………………………………………………….7 Sykes 2 Space Shuttle Challenger Disaster Purpose: Look at and summarize the key decisions that led to the disaster of the Space Shuttle Challenger January 28th, 1986. It was the first catastrophe the NASA program had to undergo. BLUF The decision to go through with the launch of the Space Shuttle Challenger resulted in the first disaster for the NASA organization. The accident destroyed the shuttle and took the lives of all seven crewmembers aboard the space shuttle. The combination of several factors such as structurally flawed O-rings, weather conditions which provided further stress on the O-rings, pressures on Thiokol management to go through with the launch, and a buildup of compliancy for flaws in the design of the shuttle. This accident proved to be a wake-up call for the space flight program, resulting in a list of procedures by the Roger Commission recommending the adherence of more strict standards. It also re-established a lesson in the fact that space exploration can be treacherous and has no room for compliancy. Background The Space Shuttle Challenger Disaster is an incident that still resonates throughout history and is memorialized before every NASA flight. The accident took the lives of seven crewmembers including Commander Francis Scobee, Pilot Mike Smith, Mission Specialists Judy Resnik and Ellison Onizuka and Ron McNair, and Payload specialists Greg Jarvis and Christa McAuliffe. This was going to be the Challengers tenth mission into space. The accident happened on January 28th, 1986; the vehicle broke up after 73 seconds of ascent (Chow). The mission was plagued with several ill factors. The flight was pushed back several times because of weather conditions. The flight appeared to be cleared for launch on January 27th; however, it was again stalled by weather. Finally, on the 28th, the flight was cleared despite excessively cold weather. Key Decision While the Challenger disaster had several factors that led to the accident, the key factor was the malfunction of one O-ring. The main purpose of the O-ring to keep searing hot gases from escaping between the joints of the booster segments (Evans, 242). These “searing hot gases” faced the External Tank, Figure 1: Diagram of O-Ring (Welch) which contained two million liters of very volatile liquid propellants (Evans, 242). It would have exploded initially, if not for a chunk of solid fuel that plugged the O-ring hole momentarily; however, the plug could not remain in place. If the solid state of fuel stayed plugged in the hole Sykes 3 then this launch may have proceeded as normal (Evans, 242). Unfortunately, the Challenger hit a wind shear that was severe enough to dislodge the plugged joint a minute into the flight. A flame surfaced and quickly made its way towards the external tank (Evans, 244). It was directed towards the external tank, which led to the disintegration of the Challenger. Eventually the Reaction Control System was hit which set up a hypergolic burning of propellants. The Challenger, now in several large pieces, made its descent into the Atlantic Ocean (Evans, 246-247). The disaster just explained can be tracked with a timeline starting with lift-off. From lift-off to 3.75 seconds, dark puffs of smoke seen by the Challenger’s right SRB indicated that the hot gases burned through the O-ring seals in a booster joint (Welch). At 7.72 seconds the ship is able to perform a normal roll (Welch). 12 seconds into the flight, the black smoke disappears because the faulty O-ring and joint was able to seal itself (Welch). 36.99 seconds into launch Challenger hit the wind shear that reopened the damaged booster joint. 58.79 seconds, a flicker of flame is apparent as hot gases begin to burn a hole through the booster joint’s metal casing (Welch). 64.66 seconds, the flames melt a hole in the external tank which then mixes with the leaking hydrogen from the tank (Welch). 73.12-73.14 seconds, the bottom of the ship’s external fuel falls off which let go a significant amount of the liquid hydrogen propellant (Welch). At this same time, the right booster breaks from the lower strut and pierces the external tank causing an explosion that engulfs the Challenger (Welch). It only took the Challenger a minute and 13 seconds from launch to be completely destroyed. The decision to initiate the launch in excessively cold weather proved to be a fatal flaw as well. The flight was already pushed back after cold weather was observed on January 25th, 1985. However, the day that the flight actually happened proved to be even colder than the 25th. The temperature on the day of the launched dipped to around 13 degrees Celsius – one of the lowest for a shuttle launch in history. Overall, it was the first occasion where there was a link observed between cold weather and the O-rings being damaged (Evans, 253). The decision to carry on with the launch in the weather conditions was heavily debated. In a teleconference Thiokol’s vice-president in engineering, Bob Lund, argued that the SRBs were not fit to fly at temperatures below 12 degrees Celsius. Many NASA officials actually questioned Lund’s team logic as Lund had no evidence to prove his position (Evans, 262). Lund made no progress with anyone and eventually executive Jerry Mason told Lund to, “take off your engineering hat and put your management hat”. Lund went on to change his vote for launch and his position for the launch (Evans, 263) Along with this, the application of zinc chromate putty, which was supposed to be used as a thermal barrier to keep combustion gas cleared from the O-rings, contributed to the destruction of the Challenger. This putty would perform “pressure actuation” and compress the air ahead of the primary O-ring. If the pressure actuation was delayed the combustion gases could blow by the O-ring and the seal would fail (Evans, 252). It was also discovered that small traces of rain water was in the SRB joints. It was then hypothesized that STS-51L was sitting on pad 39B for almost 39 days. This was exposed to more rainfall than normal and could help dislodge the O-ring (Evans, 253). Sykes 4 Another factor that played in the O-ring was that the inspections before the flight, starting in 1981, showed erosion of the right-hand SRB’s primary O-ring that was actually caused by combustion gases. Experts say that the erosion caused the blow holes inside the putty for pressure actuation. Thus, the manufacturer of the original putty discontinued the product and introduced new one in 1982. However, it was eventually again substituted for the original (Evans, 252). Another problem that encompassed the O-ring problems involved the decision-making process. The O-ring and its function were considered “Criticality 1” which means it is an aspect that did not have a backup feature or facility and could result in the destruction of the shuttle along with the crew. While managers and astronauts realized this, they did not sufficiently see it as a detrimental problem as they felt that “. . . the Solid Rocket Booster was probably one of the least worrisome things we had in the programme” (Evans, 252). In fact on her ninth mission, the last successful flight Challenger had made, the ship had experience O-ring erosion and blow-by at the field joints. However, neither of these problems was diagnosed on the Flight Readiness Review for the next mission. Instead of looking problematic areas, Thiokol recommended for their testing equipment to be redesign. Eventually, Thiokol closed the issue with the O-ring because they experienced “satisfactory test results” (Evans, 254-255). This was very flawed thinking as exemplified by one Thiokol structural engineer, Boisjoly, and physicist Richard Feynman, both of whom noticed the flaws of the O-ring. They agreed that since the O-ring survived other shuttle flights the risk became lower and lower. Soon enough, the standards began to erode away because of this interpretation of acceptable risk (Evans, 253). One other factor that was key was that many contracted employees at the KSC were working 72 hour weeks and 12 hour shifts. This made safety even more of a risk; fatigue can hamper how people focus and work (Evans, 255). Overall there was a lot of pressure on management to make the launch happen due to several push backs of the launch schedule. This facilitated the wrong decisions made by key officials, such as the Launch Director or Shuttle Programme Manager, because they were not “privy” to the issues at hand. (Evans, 264) Lessons Learned In response to the shuttle’s disaster all shuttle missions were halted at the recommendation of a special team, The Roger Commission, created by President Regan to determine the cause of the accident. As a result, modifications to existing and new space shuttles were made such as an improved O-ring design and a crew bail-out system. Missions did not resume until September of 1988 (“Space Shuttle Challenger Disaster”). Roger Commission came down hard with a list of recommendations for when it came to the design of the SRB joints. According to the commission the SRB had to be insensitive to factors such as: Dimensional tolerances. Sykes 5 Transportation and handling. Assembly procedures. Inspection and test procedures. Environmental effects. Internal case operating pressure. Recovery and reuse effects. Flight and water impact loads The certification of the new design needed to include tests that duplicate actual launch configurations closely as possible and that goes over full range of operating conditions that include temperatures (Presidential Commission). The Roger Commission suggested the creation of an oversight committee to ensure that the appropriate recommendations were made and too evaluate the certification requirements (Presidential Commission). The Commission also targeted maintenance procedures recommending that NASA establish a system for analyzing and reporting performance trends for items that are deemed Criticality 1 (Presidential Commission). In assessing the Orbiters NASA needed to develop a maintenance inspection plan, execute periodic structural checks and support the maintenance and spare parts program (Presidential Commission). The practice of removing parts for one Orbiter to help supply another needed to cease (Presidential Commission). In an attempt to increase the survivability of the crew members some improvements were made. Upgraded brakes and tyres were installed in light of what happened to the Challenger (Presidential Commission). Also, a drag chute was created to support the Shuttle’s high speed touchdowns. Finally, an escape pole which could be used for bail outs was implemented (Presidential Commission). However, this pole could only be used when the ship is in controlled gliding patterns and not at an altitude much higher than when the challenger disintegrated (Evans, 265). Along with improvements of the ship, astronauts were now equipped with a partial-pressure suit that could provide hyperbaric protection for ascent and also helped with cold-water immersion protection in an event of a bail-out over an ocean. The suit was also equipped with a parachute and life raft (Evans, 265) A general overview of the lessons learned from the review exposes that there was a distinct breakdown in communications that existed between top level management all the way to lower level employees and engineers. As a result, managers were pressured to influence employees into breaking certain rules to maintain flight schedules (Safety Division). The space program was inherently flawed based on the fact that it was built on the grounds of innovation; resulting in the waiving of rules. From the Challenger disaster we can learn that there is a need to follow management rules and have effective communication between top level Sykes 6 management and lower level employees as they perform the tasks necessary for improving space shuttle safety (Safety Division). The communication between different layers of the work force was only one aspect that was criticized hard. The Commission called for improved communications by eliminating the tendencies at the Marshall Space Flight Center (Presidential Commission). This was done by changing of the personnel, organization and indoctrination. Also, The Flight Readiness Reviews and Mission Management Team meetings became a requirement to record (Presidential Commission). The Flight Crew Commander or a representative of the crew had to attend the Flight Readiness Review, participate in an accepted replica vehicle for flight and verify that the crew is adequately prepared for the flight (Presidential Commission). Another concern the Rogers Commission found was the glaring short periods between individual missions. When looking over the future flight plans for Challenger it indicated an over the top flight rate. As a result, NASA created a mandate that stated a minimum of three weeks should separate between each shuttle flight (Evans, 266). While NASA kept strict regulations and tried to create safer environment for shuttle launches for a while, another disaster unfortunately occurred on February 1st, 2003 when shuttle Columbia disintegrated a few minutes after launch (Watson). This was due to a chunk of foam insulation peeling off the shuttle’s fuel tank, creating a tremendous hole into the shuttle wing (Watson). There are glaring similarities between these two launches: in both instances, problems that should have been addressed before launch were categorized as “acceptable risks” (Watson). Personal Lessons Learned After researching the Space Shuttle Challenger Disaster all I could think about was how with all these flaws how could anyone decided to go through with the launch? I do understand the mantra that space exploration is a new frontier, and just like any new frontier death and unfortunate mishaps may follow. The Challenger Disaster marked the first of two extreme accidents, but before that NASA did a good job at keeping launches safe. Because of this fact I believe NASA officials began to become more compliant. The organization forgot that space exploration was dangerous and requires an extreme amount of precision to execute a successful flight. The lesson I learned after researching this disaster is that there needs to be strict procedures and rigid protocols. NASA had some idea that the O-ring was flawed. Also, the weather conditions were less than ideal which contributing to the disaster. It is important to remember that when dealing with massive shuttles and speeds of upwards 17,000 mph, a small flaw could mean the destruction of a launch and the loss of lives. With lives at stake and the amount of money going into these launches there needs to be rules that only strict protocols could provide. With that being said, I admire and acknowledge the ability of resilience and not conceding defeat is one of the hardest things. Space Exploration is a high risk situation and can involve an inflated amount of danger for those involved. Hindsight is 20/20; however, we must not become compliant and realize that if there is a problem we need to look to strict procedural action and know not to go through with the mission. Sykes 7 Works Cited Bergin, Chris. "Remembering the Mistakes of Challenger." NASASpaceFlight.com. NASA, 28 Jan. 2007. Web. 30 Sept. 2013. Chow, Denise. "Space Shuttle Challenger Disaster FAQ: What Went Wrong." Space.com. Space.com, 25 Jan. 2011. Web. 30 Sept. 2013. Dunbar, Brian. "Space Shuttle Overview: Challenger (OV-099)." NASA. NASA, 12 Apr. 2013. Web. 30 Sept. 2013. Evans, Ben. Space Shuttle Challenger. Chichester, UK: Praxis, 2007. Print. (1st Book Source) Safety, Division. "Lessons Learned From Challenger." Lessons Learned From Challenger(1988): n. pag. Ocw.mit.edu. MIT. Web. 31 Oct. 2013. "Space Shuttle Challenger Disaster." Space Shuttle Challenger Disaster. Vic Stathopoulos, 15 Aug. 2013. Web. 31 Oct. 2013. United States. Presidential Commission on the Space Shuttle Challenger Accident. Report to the President. 5 vols. Washington: The Commission, 1986. Print. (2nd Book Source) Watson, Traci. "25 Years Later: How the Challenger Disaster Brought NASA down to Earth." USATODAY.COM. USA Today, 30 Jan. 2011. Web. 14 Nov. 2013. Welch, Charles. "Space Shuttle Challenger." Space Shuttle Challenger. The Ozone Hole Inc, n.d. Web. 14 Nov. 2013.