AECAPC_Europe_2005_InteractionOfData

advertisement

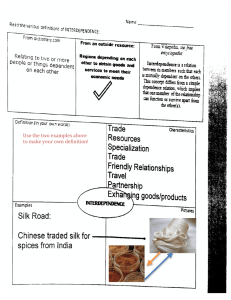

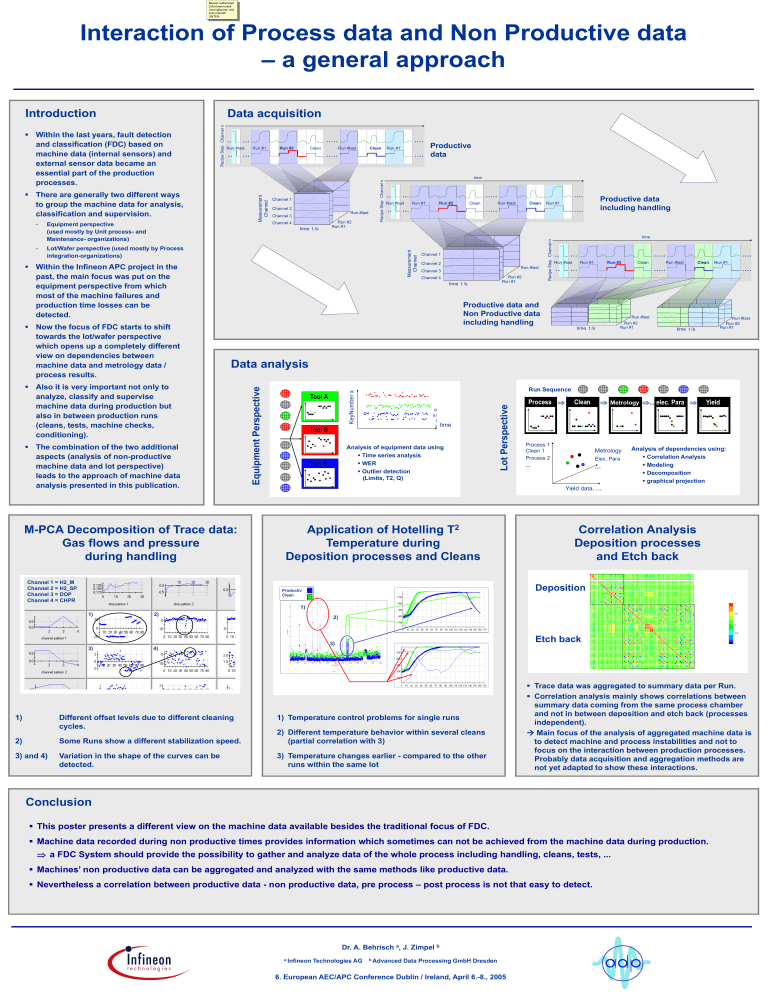

Besser aufbereiten Schichtenmodell Verenglischen und KommentaR UNTEN Interaction of Process data and Non Productive data – a general approach Introduction .. Run #last .. Run #2 Clean Run #last Clean Productive .... data Run #1 ..... ... Measurement Channel Equipment perspective (used mostly by Unit process- and Maintenance- organizations) Channel 1 Channel 2 Run #last Channel 3 Channel 4 time t /s Run #2 Run #1 .. Run #last .. ..... ... Run #1 Run #2 Clean .... Run #last Clean Productive data including handling Run #1 ..... ... .... Lot/Wafer perspective (used mostly by Process integration-organizations) Within the Infineon APC project in the past, the main focus was put on the equipment perspective from which most of the machine failures and production time losses can be detected. Channel 2 Run #last Channel 3 Channel 4 time t /s Run #2 Run #1 .. Run #last .. ..... ... Run #1 Run #2 Clean .... Run #last Clean Run #1 ..... ... Productive data and Non Productive data including handling .... Run #last Run #2 Run #1 time t /s Run #last Run #2 Run #1 time t /s M-PCA Decomposition of Trace data: Gas flows and pressure during handling Channel 1 = H2_M Channel 2 = H2_SP Channel 3 = DOP Channel 4 = CHPR Tool A Tool B time Analysis of equipment data using Time series analysis WER Outlier detection (Limits, T2, Q) Tool C Lot Perspective The combination of the two additional aspects (analysis of non-productive machine data and lot perspective) leads to the approach of machine data analysis presented in this publication. Run Sequence KeyNumber x Also it is very important not only to analyze, classify and supervise machine data during production but also in between production runs (cleans, tests, machine checks, conditioning). Equipment Perspective Data analysis t i m e Now the focus of FDC starts to shift towards the lot/wafer perspective which opens up a completely different view on dependencies between machine data and metrology data / process results. Channel 1 Recipe Step Channel n time Measurement Channel - Run #1 .... time There are generally two different ways to group the machine data for analysis, classification and supervision. - ..... ... Recipe Step Channel n Within the last years, fault detection and classification (FDC) based on machine data (internal sensors) and external sensor data became an essential part of the production processes. Recipe Step Channel n Data acquisition Process Clean Process 1 Clean 1 Process 2 ... Metrology ... elec. Para Metrology Elec. Para … Yield Analysis of dependencies using: Correlation Analysis Modeling Decomposition graphical projection Yield data, … Application of Hotelling T2 Temperature during Deposition processes and Cleans Correlation Analysis Deposition processes and Etch back Deposition Productiv Clean 1) 1) 2) 2) Etch back 3) 3) 1) 4) Different offset levels due to different cleaning cycles. 1) Temperature control problems for single runs 2) Some Runs show a different stabilization speed. 2) Different temperature behavior within several cleans (partial correlation with 3) 3) and 4) Variation in the shape of the curves can be detected. 3) Temperature changes earlier - compared to the other runs within the same lot Trace data was aggregated to summary data per Run. Correlation analysis mainly shows correlations between summary data coming from the same process chamber and not in between deposition and etch back (processes independent). Main focus of the analysis of aggregated machine data is to detect machine and process instabilities and not to focus on the interaction between production processes. Probably data acquisition and aggregation methods are not yet adapted to show these interactions. Conclusion This poster presents a different view on the machine data available besides the traditional focus of FDC. Machine data recorded during non productive times provides information which sometimes can not be achieved from the machine data during production. a FDC System should provide the possibility to gather and analyze data of the whole process including handling, cleans, tests, ... Machines’ non productive data can be aggregated and analyzed with the same methods like productive data. Nevertheless a correlation between productive data - non productive data, pre process – post process is not that easy to detect. Dr. A. Behrisch a, J. Zimpel b a Infineon Technologies AG b Advanced Data Processing GmbH Dresden 6. European AEC/APC Conference Dublin / Ireland, April 6.-8., 2005