Oxy - Supporting-PAA

advertisement

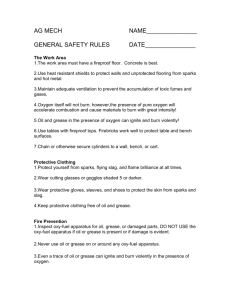

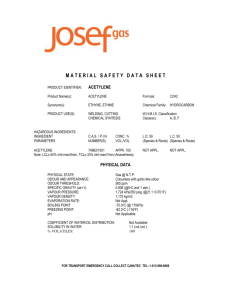

Welding 10 - Oxy-Fuel Welding Safety Oxy-Fuel Welding Safety - Objective Recognize hazards associated with oxy-acetylene welding equipment (i.e., tanks, hoses, gauges) and take the necessary measures to avoid unintentional injuries, including those caused by flashback and backfire The oxyacetylene welding process uses a combination of oxygen and acetylene gas to provide a high temperature flame. Oxyacetylene Welding (OAW) Outfit The term oxyacetylene gas-welding outfit refers to all the equipment needed to weld. Typical Oxyacetylene Welding (OAW) Station Oxy-Fuel Welding Safety 1 Quiz Time In your own words describe the objective for this unit. _________________________________________________________________________________________________ _________________________________________________________________________________________________ _________________________________________________________________________________________________ ____________________________________________________________________________________________ Oxygen Cylinders Oxygen is much more dangerous than many people believe. We generally encounter oxygen as a gas and in this state it is colorless, odorless, and tasteless. Oxygen will not explode or burn, however oxygen increases the flammability of almost everything. Oxygen will also cause anything that is burning to burn hotter and faster. Fires in atmospheres enriched oxygen are very hard to extinguish, and these fires will spread rapidly. The normal oxygen content in air is around 21 percent but at slightly higher oxygen concentrations, for example 25 percent, combustible materials, including clothing fabrics, ignite more easily and burn much faster. Nearly all materials including textiles, rubber and even metals will burn vigorously in oxygen Oxygen is not the same thing as air. Pure oxygen will react with materials like steel and oil in a completely different way than air. Oxygen is very reactive. Pure oxygen, at high pressure, such as from a cylinder, can react violently with common materials such as oil and steel. For example oil may catch fire spontaneously and when exposed to pressurized oxygen and contained, it may explode. See YouTube video of steel wool burning in an enhance oxygen environment. http://supporting-paa.wikispaces.com/Oxygen+-+steel+cutting Oxy-Fuel Welding Safety 2 Oxygen cylinders are filled to an extremely high pressure. Oxygen is stored within cylinders of various sizes and pressures ranging from 2000-2640 PSI. (Pounds Per square inch) In order to accommodate these extreme pressures, oxygen cylinders are forged from solid armor plate steel. No part of the cylinder may be less than 6.35mm (1/4”) thick Under normal operating conditions pressurized gas cylinders are quite safe, but when a gas cylinder is inadvertently exposed to fire or high temperatures. The pressure inside the cylinder will increase dramatically, leading to the possibility of a violent explosion. Pressure-relief devices are installed on most cylinders to prevent the rupture of the cylinder. Oxygen cylinders incorporate a thin metal “pressure safety disk” made from stainless steel. This disk is called a rupture disk. These disks are designed to rupture prior to the cylinder becoming damaged by an extreme increase in pressure. Care should be taken when handling and storing cylinders to prevent damage to the pressure-relief devices. Oxy-Fuel Welding Safety 3 Quiz Time The type of safety device is used on a oxygen cylinder. a. A fusible plug b. A check valve c. A pressure safety disk d. A spring-loaded plug A slight increase in the percentage of oxygen in air will result in _________________________________________________________________________________________________ _________________________________________________________________________________________________ ___________________________________________________________________________________________ Mixing Oil and pressurized oxygen may result in an __________________. Oxy-Fuel Welding Safety 4 Gas Cylinder Transportation Never transport cylinders without the safety caps in place Cylinder caps must be securely in place when transporting cylinders. Always chain cylinders to a secure cart or some other object that cannot be toppled easily. When unsecured, and uncapped cylinders are knocked over and the cylinder valve may break releasing and high-pressure gas. Damaged cylinders can become uncontrolled rockets or pinwheels Rocketing cylinders have caused severe injury and damage. Oxy-Fuel Welding Safety 5 Quiz Time Failure to transport gas cylinders safely may cause _________________________________________________________________________________________________ _________________________________________________________________________________________________ ___________________________________________________________________________________________ Oxy-Fuel Welding Safety 6 Pressure Regulators for Cylinders Pressure regulators for cylinders reduce high cylinder pressure to lower working pressure. Most regulators have two gauges. One gauge shows the cylinder pressure and the second gauge shows the working pressure (line pressure) Regulators are shut off when the adjusting screw is turned out completely. Regulators maintain a constant torch pressure even when cylinder pressure vary. Oxy-Fuel Welding Safety 7 Oxyacetylene Regulator Hoses Hoses are fabricated from nylon mesh sandwiched between two rubber tubes. Oxygen hoses are green in color and have right hand thread. Acetylene hoses are red in color with left hand thread. Acetylene (fuel) gas connections have left hand threads Left hand threads can be identified by a grove in the body of the nut Oxygen gas fittings have right hand threads. These fittings do not have a groove in the body of the nut Oxy-Fuel Welding Safety 8 Quiz Time The hose nuts for oxygen and acetylene differ greatly, because the acetylene hose nut has: a. a right hand thread. b. a grove cut around it. c. the words “Fuel Gas” stamped on it. d. all of the above. Oxy-Fuel Welding Safety 9 Check Valves & Flashback Arrestors Check valves allow gas flow in one direction only Flashback arrestors are designed to eliminate the possibility of an explosion at the cylinder. Combination Check/ Flashback Valves can be placed at the torch or regulator. Oxy-Fuel Welding Safety 10 Victor Torch Safety YouTube video Some manufactuers of oxyacetylene torches have fashback arrestors built into the handle Quiz Time Describe the purpose of an oxyacetylene check valve. _________________________________________________________________________________________________ _________________________________________________________________________________________________ ___________________________________________________________________________________________ Describe the purpose of an oxyacetylene flashback arrestor. _________________________________________________________________________________________________ _________________________________________________________________________________________________ ___________________________________________________________________________________________ Oxy-Fuel Welding Safety 11 Calcium Carbide Calcium carbide mixed with water is used to produce virtually all acetylene gas.. For many years, miners’ lamps produced acetylene by adding water, a drop at a time, to lumps of carbide. Acetylene mixed with oxygen produces the hottest flame for welding and cutting. Unfortunately, acetylene gas is highly volatile, and it is very unstable. Acetylene, which is not stored in an approved cylinder, is extremely unstable at pressures above 15 PSI (Pounds per Square Inch) If acetylene gas is handled improperly it may explode! Oxy-Fuel Welding Safety 12 Quiz Time Acetylene, which is not stored in an approved cylinder, is extremely unstable at pressures above ________PSI. Oxy-Fuel Welding Safety 13 Acetylene Cylinders Pressurized acetylene is stored in cylinders specially designed to safely store the gas. Acetylene tanks produced before 1984 often incorporated small amounts of asbestos, to add stability without flammability. Acetylene cylinders are filled with a very porous substance and a solvent called acetone. The filler and the acetone absorb and stabilize the acetylene. Acetylene cylinders should always be stored in the upright position to prevent the acetone form escaping thus causing the acetylene to become unstable. Acetylene Cylinder Label Oxy-Fuel Welding Safety 14 Acetylene cylinders are protected from explosion by fusible metal plugs. These fusible plugs are designed to melt at 212° F (100 °C). Fusible plugs are located on top and bottom of the cylinder. These devices are an integral part of the cylinder, rather than being installed in the cylinder valve. Oxy-Fuel Welding Safety 15 Some small acetylene cylinders are equipped with fusible plugs in the valve body. Acetylene Valves Acetylene cylinder shut off valves should only be opened 1/4 to 1/2 turn. This will allow the cylinder to be closed quickly in case of fire. Oxygen and Acetylene Regulator Pressure Settings Regulator recommended pressure varies with different torch styles and tip sizes. Always be sure to check the torch manufactures data for optimum pressure settings. Regulator Pressure Settings The maximum safe working pressure for acetylene is 15 PSI! Oxy-Fuel Welding Safety 16 Quiz Time Acetone helps to absorb and _____________________________ acetylene. The device that protects an acetylene cylinder from explosion is called ______________________. Why should acetylene cylinders only be opened ¼ to ½ turn? _________________________________________________________________________________________________ _________________________________________________________________________________________________ ___________________________________________________________________________________________ Why is the area above 15 psi often marked with a red band on an acetylene pressure regulator? _________________________________________________________________________________________________ _________________________________________________________________________________________________ ___________________________________________________________________________________________ Oxy-Fuel Welding Safety 17 Further Reading http://www.aws.org/educators/Library/0000/000631.ppt. http://www.ccohs.ca/oshanswers/chemicals/compressed/compress.html http://www.airproducts.com/~/media/Files/PDF/company/safetygram-15.pdf http://www.victortechnologies.com/index.php/victor/breaking-news/552.html Oxy-Fuel Welding Safety 18