WELDING/BRAZING/TORCH

advertisement

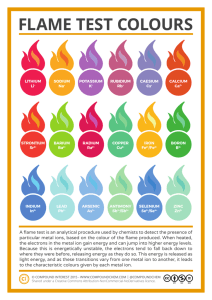

OXY-ACETYLENE CUTTING AND WELDING UNIT 23-24 I CAN I can identify oxyacetylene equipment I can describe the safe startup, settings and shutdown of the oxyacetylene equipment. I can explain the correct operating procedure for brazing, heating and cutting. Oxy/Acetylene Fusion – Process of joining two metals by fusioning (melting) the adjoining surfaces. – Move molten puddle back & forth between the metal. Holds very little Brazing – Process of joining two metals by fusioning (melting) with a third metal bronze – Brazing flame is 800 degree (F) or below. – Base metal is not brought to molten stage. THE FIRE TRIANGLE TO PRODUCE FIRE, THREE THINGS MUST BE PRESENT AT THE SAME TIME The basic process that allows the oxy-acetylene equipment to work. OXYGEN HEAT FUEL Oxyfuel Gas Welding & Cutting Oxyfuel is a group of processes that use heat generated as a result of the combustion of a mixture of oxygen and a combustible gas. Acetylene is the most commonly used in oxyfuel processes. Propane is another good source of fuel. The flexibility and mobility provided by oxyacetylene welding allow its use in all metalworking industries. Oxyfuel welding is primarily used for maintenance, general fabrication, and repair work. Chemicals Used Oxygen – Colorless, odorless, tasteless gas – Supports combustions & increase heat – Produce by cooling air to a low temperature and turning it into liquid where the oxygen is separate out. Acetylene – Colorless, has a very distinctive odor – Highly flammable – Produce by mixing calcium carbide (coke + limestone burnt together) and water yields acetylene and calcium hydroxide. ADVANTAGES The relative cost of the equipment is low. No electricity is required for this process. Can be used for welding in all positions because no electrical cables are required and the operator has precise control of the process. This process is also extremely portable. Can be used on both thick and thin materials, which makes it a very versatile process. Very clean, producing no slag or spatter that must be removed from the weld. Produces high quality welds when done properly. LIMITATIONS The materials that can be welded are limited primarily to ferrous materials. Creates a “Hot Zone”, fire hazard, because of the sparks and flame generated in the welding process. Requires the handling of high pressure gases. The combination of oxygen with a fuel gas creates the potential for flashbacks and backfires. The process can often be slow when compared to other types of welding processes. Welding is limited to oxy-acetylene or oxyMAPP. TIP HEIGHT This slide depicts cuts that have been made when the cutting tip is too high or too low. If the cutting tip height is too high, the top edge of the cut is beaded or rounded. The cut face is not smooth and often is only slightly beveled because the preheat effectiveness is partially lost because the tip is held too high. In this situation, the cutting speed is reduced because of the danger of losing the cut. If the cutting tip height is too low, the cut had grooves and deep drag lines caused by an unstable cutting action. In this case, part of the preheat cone burns inside the kerf where normal gas expansion deflects the oxygen cutting stream CUTTING The preheat flame performs four functions: To preheat the base metal to ignition temperature. To maintain a protective shield around the cutting stream. To maintain the reaction temperature. To penetrate rust, scale, and other foreign properties on the base metal. CUTTING Before cutting action can start, the steel must be preheated to a bright cherry red. When the red spot appears, depress the cutting oxygen lever slowly. Move steadily across base metal, keeping the luminous inner cones approximately 1/8 inch above metal. While moving across the base metal, if cutting stops, release the cutting lever, preheat again and restart the cut. Use a smooth straight edge to steady and guide torch movement, if necessary. Type of Flame Oxygen flame – More oxygen is used than acetylene – Used on torch cutting or heating. – Flame is noisy Acetylene – More acetylene than oxygen. – Flame produces a black soot and is worthless Neutral – Oxygen & acetylene same pressures – Quiet flame – Used on brazing. FLAMES There are three basic flame types used in oxyfuel processes. The neutral flame is used in most welding, brazing, soldering and cutting because it does not carburize or burn the metal. A neutral flame has a bright blue outer envelope with a sharp inner cone visible. It is called a neutral flame because there is an approximate one-to-one mixture of acetylene and oxygen. This results in a flame that is chemically neutral. The brilliant white cone should be approximately 1/16” to ¾” long, depending on the welding tip size. Any variation from the one-to-one oxygen-acetylene mixture will alter the flame characteristics. When excess oxygen is forced into the oxyacetylene mixture, the resulting flame is said to be oxidizing The oxidizing flame has excess oxygen beyond the neutral flame. It is pale blue in color without the clearly defined inner cone and characterized by a hissing sound. An oxidizing flame is sometimes used for brazing. The carburizing or reducing flame is caused by excess acetylene and is characterized by a feather flame that contracts towards the welding tip and inner cone. A carburizing flame can be identified by observing the existence of three flame zones instead of the usual two found in the neutral flame. The end of the brilliant white cone is not as well defined and is surrounded by an intermediate white cone, that has a feathery edge in addition to the bluish outer envelope. Equipment Cylinder Sizes – Oxygen—green color cylinder » Sizes—244, 122, or 80 cubic feet. – Acetylene—red color cylinder » Sizes—300, 100 or 60 cubic feet » Contains acetone which absorbs large amounts of acetylene without changing the nature of the gas. Cylinder Pressure (Full pressurize cylinders) – Oxygen—2200 psi at 70 degree244 cubic feet – Acetylene—250 psi at 70 degree100 cubic feet. Operating Pressure (NEVER ADJUST ACETYLENE ABOVE 15 PSI) – Cutting—5 parts oxygen to 1 part acetylene » Setting—35 oxygen, 7 acetylene – Brazing—1 part oxygen to 1 part acetylene » Setting 3 oxygen, 3 acetylene Cylinders Acetylene Bottle Oxygen Bottle Equipment II Cylinder Valve – Oxygen & acetylene valves—open all the way. » Allows the gases to flow one way—out. Gages – 1st gage will show the pressure in the cylinders » Oxygen 0 to 4000 psi; Acetylene 0 to 400 psi – 2nd gage will show the working line pressure. » Oxygen 0 to 100 psi; Acetylene 0 to 30 (Never go above 15 psi) Regulators – Used to adjust the line pressure. – Double stage regulators. – Turn regulator knob clockwise to increase pressure. NOZZLES Regulators Equipment III Nuts – Acetylene nuts are grooved—counter threads. » Turn counter clockwise to tighten Torch body – Two passages for the gases to travel. Hoses – Acetylene—red; Oxygen—green Brazing tips – Numbered 0—15; Larger the number the larger the hole. Cutting tips – Have 4 preheat orifices (holes) Oxygen Pre-Heat Valve – Adjusts your flame Brazing Head Setup Torch Head Setup Cutting Tip Safety Concerns Lens—Use a number 5 lens. – Used to see the hot metal from the cold metal. Acetylene Adjustment – Never go above 15 psi working pressure. Check for leaks. – Use non-organic soap and water. Brush soap and water on connection and see if bubbles form. If bubbles appear—fix. Use long sleeve, long pants, close toe shoes, leather gloves. Backfire—tip is too close to metal, causes the flame to blow out. Caused by overheating, wrong pressure. Flashback—flame goes into torch head, makes a shrill hissing noise. Cause—hose leak. Shut off acetylene, check and fix. SUMMARY Most popular gases for heating, cutting, welding metal are acetylene & propane. Acetylene is shut off first followed by oxygen. 3-types of flames – oxidizing flame(excess oxygen) hottest flame; carbonizing flame(excess acetylene) cooler flame; neutral flame(correct balance of acetylene/oxy SUMMARY Check leaks with soapy water. NEVER!!! NEVER use oil or oily substance around oxygen regulators, fittings, etc. Slag is an insulator rather than steel. Will not cut. Clearance prevents bevel cuts(distance between tip and base metal. SUMMARY Oxygen must be 99.5% pure to support the combustion of iron. Cutting or heating galvanized metal creates a toxic fume. Prevent Backfire(tip to close to work, dirty tip, tip overheating) & flashback(leakage)