gas welding - SNS Courseware

advertisement

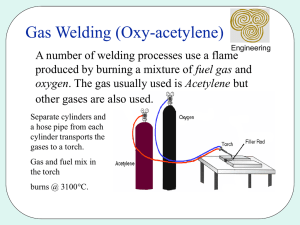

GAS WELDING Sound weld is obtained by selecting proper size of flame, filler material and method of moving torch The temperature generated during the process is 33000c When the metal is fused, oxygen from the atmosphere and the torch combines with molten metal and forms oxides, results defective weld Fluxes are added to the welded metal to remove oxides Common fluxes used are made of sodium, potassium. Lithium and borax. Flux can be applied as paste, powder,liquid.solid coating or gas. GAS WELDING EQUIPMENT... • 1. Gas Cylinders • Pressure • Oxygen – 125 kg/cm2 • Acetylene – 16 kg/cm2 • 2. Regulators • Working pressure of oxygen 1 kg/cm2 • Working pressure of acetylene 0.15 kg/cm2 • Working pressure varies depends upon the thickness of the work pieces welded. • 3. Pressure Gauges • 4. Hoses • 5. Welding torch • 6. Check valve • 7. Non return valve Oxy-Acetylene welding TYPES OF FLAMES… • Oxygen is turned on, flame immediately changes into a long white inner area (Feather) surrounded by a transparent blue envelope is called Carburizing flame (30000c) • Addition of little more oxygen give a bright whitish cone surrounded by the transparent blue envelope is called Neutral flame (It has a balance of fuel gas and oxygen) (32000c) • Used for welding steels, aluminium, copper and cast iron • If more oxygen is added, the cone becomes darker and more pointed, while the envelope becomes shorter and more fierce is called Oxidizing flame • Has the highest temperature about 34000c • Used for welding brass and brazing operation Three basic types of oxyacetylene flames used in oxyfuel-gas welding and cutting operations: (a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing flame. Three basic types of oxyacetylene flames used in oxyfuel-gas welding and cutting operations: (a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing flame. GAS CUTTING • Ferrous metal is heated in to red hot condition and a jet of pure oxygen is projected onto the surface, which rapidly oxidizes • Oxides having lower melting point than the metal, melt and are blown away by the force of the jet, to make a cut • Fast and efficient method of cutting steel to a high degree of accuracy • Torch is different from welding • Cutting torch has preheat orifice and one central orifice for oxygen jet • PIERCING and GOUGING are two important operations • Piercing, used to cut a hole at the centre of the plate or away from the edge of the plate • Gouging, to cut a groove into the steel surface GAS CUTTING… Manual Gas Cutting What is Gas Welding? • Gas Welding relies on the combustion of fuel gases, usually Oxygen and Acetylene to heat metals at the welding point • Widely used in welding tubes and pipes • Commonly referred to as oxyacetylene welding Main Components of Gas Welding • Oxygen and Fuel Cylinders • Two-stage Regulators (one per tank) • Two Hoses – Green (Oxygen) – Red (Fuel) • Check Valve • Non-return Valve • Welding Torch Dangers of Gas Welding • Burns • Eye Damage – Retinal burning and cataracts • Heat Exposure – Torch burns at around 6000° F Dangers of Gas Welding • Asphyxiation – Leaks of poisonous gases – Confined space welding without proper ventilation • Explosions/Fire • Due to ignition of leaking gases • Acetylene very unstable when stored above 15 psi Injury Statistics • Nearly 365,000 welding-related eye injuries occur annually • An estimated cost to employers of $467 million annually • More than half of injured workers returning to work in less than two days and 95 percent in less than seven days • Deaths occur annually due to explosions, falls while welding and burns http://www.ohsonline.com/articles/46296/ Proper Gas Welding Procedures • Inspect equipment for wear and leaks • Replace bad hoses • Use flint lighter to ignite flame • Open cylinder valves very slowly to keep sudden high pressures from exploding the regulators http://www.cdc.gov/nasd/docs/d001601d001700/d001691/d001691.html Proper Gas Welding Procedures • Open and light acetylene first, then open and adjust oxygen to a neutral flame • When finished, close valves, bleed the lines, neatly coil hoses and replace equipment. • Have a fire extinguisher accessible http://www.cdc.gov/nasd/docs/d001601d001700/d001691/d001691.html Oxyacetylene Welding (OAW) The oxyacetylene welding process uses a combination of oxygen and acetylene gas to provide a high temperature flame. Oxyacetylene Welding (OAW) • OAW is a manual process in which the welder must personally control the the torch movement and filler rod application • The term oxyfuel gas welding outfit refers to all the equipment needed to weld. • Cylinders contain oxygen and acetylene gas at extremely high pressure. Typical Oxyacetylene Welding (OAW) Station Oxygen Cylinders • Oxygen is stored within cylinders of various sizes and pressures ranging from 2000- 2640 PSI. (Pounds Per square inch) • Oxygen cylinders are forged from solid armor plate steel. No part of the cylinder may be less than 1/4” thick. • Cylinders are then tested to over 3,300 PSI using a (NDE) hydrostatic pressure test. Oxygen Cylinders • Cylinders are regularly re-tested using hydrostatic (NDE) while in service • Cylinders are regularly chemically cleaned and annealed to relieve “jobsite” stresses created by handling . Cylinder Transportation • Never transport cylinders without the safety caps in place • Never transport with the regulators in place • Never allow bottles to stand freely. Always chain them to a secure cart or some other object that cannot be toppled easily. Oxygen Cylinders • Oxygen cylinders incorporate a thin metal “pressure safety disk” made from stainless steel and are designed to rupture prior to the cylinder becoming damaged by pressure. • The cylinder valve should always be handled carefully Pressure Regulators for Cylinders • Reduce high storage cylinder pressure to lower working pressure. • Most regulators have a gauge for cylinder pressure and working pressure. Pressure Regulators for Cylinders • Regulators are shut off when the adjusting screw is turn out completely. • Regulators maintain a constant torch pressure although cylinder pressure may vary • Regulator diaphragms are made of stainless steel Pressure Regulators Gauges Using a “Bourdon” movement • Gas entering the gauge fills a Bourdon tube • As pressure in the semicircular end increases it causes the free end of the tube to move outward. • This movement is transmitted through to a curved rack which engages a pinion gear on the pointer shaft ultimately showing pressure. Regulator Hoses • Hoses are are fabricated from rubber • Oxygen hoses are green in color and have right hand thread. • Acetylene hoses are red in color with left hand thread. • Left hand threads can be identified by a grove in the body of the nut and it may have “ACET” stamped on it Check Valves & Flashback Arrestors • Check valves allow gas flow in one direction only • Flashback arrestors are designed to eliminate the possibility of an explosion at the cylinder. • Combination Check/ Flashback Valves can be placed at the torch or regulator. Acetylene Gas • Virtually all the acetylene distributed for welding and cutting use is created by allowing calcium carbide (a man made product) to react with water. • The nice thing about the calcium carbide method of producing acetylene is that it can be done on almost any scale desired. Placed in tightly-sealed cans, calcium carbide keeps indefinitely. For years, miners’ lamps produced acetylene by adding water, a drop at a time, to lumps of carbide. • Before acetylene in cylinders became available in almost every community of appreciable size produced their own Acetylene Cylinders • Acetylene is stored in cylinders specially designed for this purpose only. • Acetylene is extremely unstable in its pure form at pressure above 15 PSI (Pounds per Square Inch) • Acetone is also present within the cylinder to stabilize the acetylene. • Acetylene cylinders should always be stored in the upright position to prevent the acetone form escaping thus causing the acetylene to Acetylene Cylinders • Cylinders are filled with a very porous substance “monolithic filler” to help prevent large pockets of pure acetylene form forming • Cylinders have safety (Fuse) plugs in the top and bottom designed to melt at 212° F (100 °C) Acetylene Valves • Acetylene cylinder shut off valves should only be opened 1/4 to 1/2 turn • This will allow the cylinder to be closed quickly in case of fire. • Cylinder valve wrenches should be left in place on Oxygen and Acetylene Regulator Pressure Settings • Regulator pressure may vary with different torch styles and tip sizes. • PSI (pounds per square inch) is sometimes shown as PSIG (pounds per square inch -gauge) • Common gauge settings for cutting – 1/4” material Oxy 30-35psi Acet 3-9 psi – 1/2” material Oxy 55-85psi Acet 6-12 psi – 1” material Oxy 110-160psi Acet 7-15 psi • Check the torch manufactures data for optimum pressure settings Regulator Pressure Settings • The maximum safe working pressure for acetylene is 15 PSI ! Typical torch styles • A small welding torch, with throttle valves located at the front end of the handle. Ideally suited to sheet metal welding. Can be fitted with cutting • attachment in place of the welding head shown. Welding torches of this general design are by far the most widely used. They will handle any oxyacetylene welding job, can be fitted with multiflame (Rosebud) heads for heating applications, and accommodate cutting attachments that will cut steel 6 in. thick. • A full-size oxygen cutting torch which has all valves located in its rear body. Another style of cutting torch, with oxygen valves located at the front end of its handle. Typical startup procedures • Verify that equipment visually appears safe IE: Hose condition, visibility of gauges • Clean torch orifices with a “tip cleaners” (a small wire gauge file set used to clean slag and dirt form the torch tip) • Crack (or open) cylinder valves slightly allowing pressure to enter the regulators slowly • Opening the cylinder valve quickly will “Slam” the regulator and will cause failure. Typical startup procedures • Never stand directly in the path of a regulator when opening the cylinder • Check for leaks using by listening for “Hissing” or by using a soapy “Bubble” solution • Adjust the regulators to the correct operating pressure • Slightly open and close the Oxygen and Acetylene valves at the torch head to purge any atmosphere from the system. Typical startup procedures • Always use a flint and steel spark lighter to light the oxygen acetylene flame. • Never use a butane lighter to light the flame Flame Settings • There are three distinct types of oxy-acetylene flames, usually termed: – Neutral – Carburizing (or “excess acetylene”) – Oxidizing (or “excess oxygen” ) • The type of flame produced depends upon the ratio of oxygen to acetylene in the gas mixture which leaves the torch tip. Pure Acetylene and Carburizing Flame profiles Neutral and Oxidizing Flame Profiles Flame definition • The neutral flame (Fig. 4-1) is produced when the ratio of oxygen to acetylene, in the mixture leaving the torch, is almost exactly one-toone. It’s termed ”neutral” because it will usually have no chemical effect on the metal being welded. It will not oxidize the weld metal; it will not cause an increase in the carbon content of the weld metal. • The excess acetylene flame (Fig. 4-2), as its name implies, is created when the proportion of acetylene in the mixture is higher than that required to produce the neutral flame. Used on steel, it will cause an increase in the carbon content of the weld metal. • The oxidizing flame (Fig. 4-3) results from burning a mixture which contains more oxygen than required for a neutral flame. It will oxidize or ”burn” some of the metal being welded. Oxyfuel Gas Welding Fig : Three basic types of oxyacetylene flames used in oxyfuel-gas welding and cutting operations: (a) neutral flame; (b) oxidizing flame; (c) carburizing, or reducing flame. The gas mixture in (a) is basically equal volumes of oxygen and acetylene. Oxyfuel Gas Welding • Welding process that uses fuel gas combined with oxygen to produce flame • This flame heat melts the metals at the joint • Acetylene fuel is used in gas welding process Primary combustion process C2H2 + O2 2CO + H2 + heat • This reaction dissociates into carbon monoxide and hydrogen. Secondary combustion process 2CO + H2 + 1.5 O2 2CO2 + H2O + heat Types of flames • Neutral flame • Oxidising flame • Carburising flame Filler Metals : • • • • Additional material to weld the weld zone Available as rod or wire They can be used bare or coated with flux The purpose of the flux is to retard the Torch Used in Oxyacetylene Welding Fig : (a) General view of and (b) cross-section of a torch used in oxyacetylene valve is opened and the flame adjusted. (c) Basic equipment used in oxyfuel-gas welding. To ensure correct connections, all threads on acetylene fittings are left-handed, whereas those for oxygen are right-handed. Oxygen regulators are usually painted green acetylene regulators red. Welding practice & equipment STEPS : • Prepare the edges to be joined and maintain the proper position • Open the acetylene valve and ignite the gas at tip of the torch • Hold the torch at about 45deg to the work piece plane • Inner flame near the work piece and filler rod at about 30 – 40 deg • Touch filler rod at the joint and control the movement according to the flow of the material Torch used in Oxyacetylene Welding Fig : (a) General view of and (b) cross-section of a torch used in oxyacetylene welding. The acetylene valve is opened first; the gas is lit with a park lighter or a pilot light; then the oxygen valve is opened and the flame adjusted. (c) Basic equipment used in oxyfuel-gas welding. To ensure correct connections, all threads on acetylene fittings are left-handed, whereas those for oxygen are right-handed. Oxygen regulators are usually painted green, acetylene regulators red. Pressure-Gas Welding Process Fig : Schematic illustration of the pressure-gas welding process.