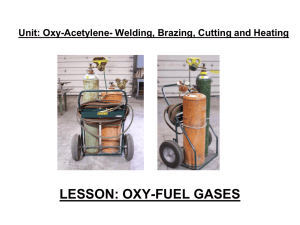

Gas Welding: Principles & Practices - Oxyacetylene Welding

advertisement

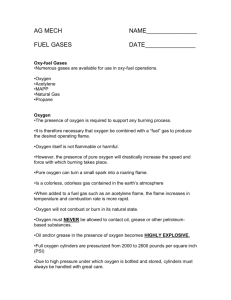

PowerPoint to accompany Welding Principles and Practices Third Edition Sacks and Bohnart Gas Welding Chapter 5 1 Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. Oxyacetylene Welding • Definition: – Join metal by heating surfaces to be joined to melting point with gas flame – Fusing metal into homogeneous mass – Letting it solidify into a single unit • Flame in cone reaches temperatures as high as 5800º to 6300ºF • Filler rod may or may not be used to intermix with molten pool 5-2 Oxyacetylene Process • During first part of this century used as major welding process both for fabrication and construction, maintenance and repair • Today use limited for industrial production purposes • Still used for brazing, soldering, welding metals with low melting points; general maintenance and repair work 5-3 History of Oxyacetylene Welding • Early Egyptians, Greeks, and Romans used alcohol or oil flame to fuse metals • In nineteenth century various gases tested – In 1847, Robert Hare fused platinum with oxyhydrogen flame – In 1880, production of oxygen and hydrogen through electrolysis of water made distribution of gases in cylinders under pressure – Late 1800s experiments done with oxygen-coal gas and air-hydrogen flames 5-4 Discoveries Leading to the Oxyacetylene Process • In 1836, Edmund Davey discovered acetylene gas • In 1862, acetylene gas produced from calcium carbide • In 1895, Thomas L. Willson produced calcium carbide commercially • Used for residential lighting • In 1895, LeChatelier discovered that combustion of acetylene with oxygen produced flame hotter than any other gas flame 5-5 Discoveries Leading to the Oxyacetylene Process • In 1900, Edmond Fouche invented high pressure acetylene torch • Later designed low pressure torch (worked on injector principle) • In 1906 Eugene Bourbonville brought first welding torch to this country • Process first used for maintenance and repair • During World War I oxyacetylene welding became production tool 5-6 Gases • Oxyacetylene welding process uses two principal gases – Oxygen and acetylene • Other gases can be used for cutting and heating – Propane – Natural gas – Mapp® gas\ 5-7 Various Fuel Gas Efficiencies Fuel Gas Btus Usable heat (ft3) (s/ft2) Normal Flame Oxygen velocity temp. per ft3 of fuel (ft/s) Acetylene Mapp®2 Propane Natural gas3 Hydrogen 1433 2381 2309 918 275 5,420ºF 5,301ºF 5,190ºF 5,000ºF 4,600ºF 12,700 5,540 5,500 5,600 7,500 1.04 2.4 4.00 1.50 0.25 17.7 7.9 11.9 15.2 36 5-8 Various Gas Cylinders Thermadyne Industries, Inc. Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5-9 Oxygen • Gaseous Chemical element in air – Necessary for life • Most abundant chemical element in crust of Earth • No color, odor, or taste • Does not burn, but supports combustion – Substances that do not burn in air will in oxygen 5 - 10 Oxygen Production • Two commercial processes used in production of oxygen – Separation of water into oxygen and hydrogen by electrolysis of water – Separation of air into oxygen and nitrogen by liquefying air 5 - 11 Oxygen Distribution Aluminum cylinders • Distributed in steel or aluminum cylinders Used for medical gases (smaller size) Made of high strength 6061-T6 alloy Steel cylinders Made from single plate of high-grade steel Heat treated to develop maximum strength and hardness Seamless, drawn-steel vessels with iron neck ring shrunk on at top and cylinder value screwed into neck High pressure – undergo rigid testing Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 12 Valve Mechanisms • Must be opened to release oxygen • Double-seated valve perfectly tight when completely open or closed – Valve protected from damage by iron cap that screws on neck ring Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 13 Gas Cylinders • Charged with oxygen at pressure of about 2,200 p.s.I. at 70ºF • Gas temperature – Increase: gas expands and increases pressure – Decrease: gas contracts and reduces pressure • Safety device on cylinder valve to blow off oxygen when excess pressure – Occurs, oxygen lost – DO NOT store where cylinder can be overheated 5 - 14 Capacity of Cylinder • Three cylinder sizes used for welding and cutting • Gas suppliers fill tanks with varying amounts – Large size: 220-244 cubic feet of oxygen • Full: 148 to 152 pounds; Empty: 130-133 pounds – Middle size: 110-122 cubic feet of oxygen • Full: 89 to 101 pounds; Empty: 79-93 pounds – Small size: 55-80 cubic feet of gas • Full: 67 pounds; Empty: 60 pounds 5 - 15 Safety Precautions • Take special care to keep oil and grease away from oxygen • When using, do not place cylinders where oil might drop of them from overhead bearings • Never use oxygen in pneumatic tools or to start internal combustion engines • Never use oxygen to blow out pipe or hose lines, dust clothes or create head pressure in tank of any kind 5 - 16 Safety Precautions • Do not store oxygen cylinders near acetylene generator, carbide, acetylene, or other fuel-gas cylinders • Do not use cylinder as roller or lift it by cap • Keep cylinders away from welding operation and close cylinder valve when work completed • Keep cylinders away from any electrical contact 5 - 17 Acetylene • Most widely used of all fuel gages – Both welding and cutting • Generated as result of chemical reaction that takes place when calcium carbide comes in contact with water • Tests show oxyacetylene flame temperatures up to approximately 6,300ºF – Very rapid rate of preheating – Burns with smoky flame, gives off carbon, has peculiar odor 5 - 18 Characteristics of an Effective Welding Fuel Gas • • • • High flame temperature High rate of flame propagation Adequate heat content Minimum chemical reaction of flame with base and filler metal Acetylene most closely matches all these requirements and used for welding purposes. 5 - 19 Acetylene Production and Distribution • Commercial acetylene made from calcium carbide – referred to as carbide – Gray, stonelike substance – Product of smelting coke and lime in electric furnace – Several sizes available • Distributed in standard steel drums – 100 pounds for use in acetylene generators 5 - 20 Acetylene Cylinders • Constructed differently from oxygen cylinders – Free acetylene should not be stored at pressure above 15 p.s.i. • Safety solved by packing cylinders with porous material saturated with acetone – Acetone – liquid chemical having property of dissolving or absorbing many times the volume of acetylene • Strong steel container (packed completely full) • Handle with care 5 - 21 Three Basic Acetylene Cylinders Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 22 Valve Mechanisms • Acetylene drawn off through valve – Some cylinders valve located in recessed top – Others valve located on convex top • Simpler in construction than oxygen valve – Does not have to stand high pressure • Opened only about 1 ½ turns – Can be turned off quickly in case of fire • Safety fuse plugs also provided 5 - 23 Capacity of Cylinder • Full cylinder of acetylene has pressure of about 225 p.s.i. • Two sizes used for welding and cutting – Large size contains 300 cubic feet of acetylene and weighs about 232 pounds when full – Small size contains 100 cubic feet and weighs 91 pounds when full • Two special sizes (10 cubic ft. and 40 cubic ft.) • Not all acetylene in cylinder can be used 5 - 24 Safety Precautions Remember acetylene will burn. It will form explosive mixture with air. • Do not leave acetylene cylinders on their sides – Store valve end up • Store cylinders in well-protected, ventilated, dry location – Away from highly combustible material or sources of heat – Keep valve cap on when not in use 5 - 25 Safety Precautions • Use warm (not boiling) water on the valve if it becomes clogged with ice (Never a flame!) – Fusible safety plugs melt at boiling point of water • Handle acetylene cylinders carefully – Damages could cause leakage • Advise supplier immediately if acetylene leaks around valve spindle when valve opened – Close spindle and move cylinder to outside area • Never tamper with fuse plugs 5 - 26 Propane Gas • Hydrocarbon present in petroleum and natural gas • Used primarily for oxyfuel heating, cutting, soldering and brazing • Sold and transported in steel cylinders containing from 20 to 100 pounds of liquefied gas – Also supplied by tank car and bulk delivery • Oxypropane flame temp less than oxyacetylene – Takes longer to bring steel to melting point – Used for soldering and alloy brazing 5 - 27 Mapp® Gas • Liquefied acetylene compound – Fuel gas for oxyfuel heating and cutting • Strong smell (aid in discovering leaks) • Mixed with oxygen, flame is 5,301ºF • Heating and cutting somewhat slower – Lower temperature • Overall expenses lower due to reduced handling costs and lower gas costs 5 - 28 Mapp® Gas • Use as fuel gas for heating and cutting is growing • Distributed in bulk or steel-cylinders – Shutoff valve similar to ones on acetylene cylinder • Liquefied and stabilized so can be used at pressures as high as 375 p.s.I. at 170ºF • Explosive limits lower than acetylene • Can be stored in free state and at high pressures 5 - 29 Safety in Handling Mapp® Gas • Forms an explosive mixture with air • Same general precautions used with handling acetylene cylinders should be observed • Safest of industrial fuels – Explosive limits of Mapp® gas vapor in air and oxygen much narrower than acetylene, same as propane and natural gas – Can smell it at concentrations as low as 0.01 percent 5 - 30 Manifold Distribution • Supplies both oxygen and fuel gas to number of work stations • Acetylene manifolds must be equipped with flash arrester to prevent flashback through manifold into cylinders • Each cylinder connected to manifold by means of an individual pigtail flash arrester and backcheck valves 5 - 31 A typical station outlet for both oxygen and acetylene pipelines from the source. Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 32 Manifold Regulator • Reduces pressure to 50 or 75 pounds in line that goes to station outlets in shop – Full pressure of 2,000 p.s.i. in oxygen manifold pipes • Work station also equipped with acetylene and oxygen regulator for further pressure control Thermadyne Industries, Inc. Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 33 Acetylene Generators • Two general types – Calcium carbide dropped into water – Water allowed to drip on carbide • Carbide-to-water generators used to produce acetylene gas for welding and cutting – Water absorbs heat given off by chemical reaction – Gas purified by bubbling through water 5 - 34 Acetylene Generator Rexarc Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 35 Acetylene Generators • Two classes of generators – Low pressure (less than 1 p.s.i.) – Medium pressure (1 to 15 p.s.i.) • Generating capacities range from – 30 cu feet of acetylene per hour for small portable – 6,000 cu feet acetylene per hour for mediumpressure generator 5 - 36 Acetylene Generator • Further classified as stationary or portable Example of portable acetylene generator Rexarc Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 37 Protective Equipment • Functions may be combined in one device or provided by separate devices – Located in main supply line, head of each branch line in manifold system or at each location where fuel gas withdrawn • Backflow protection should be provided to prevent fuel gases from flowing into oxygen system • Flashback protection should be provided to prevent flame from passing into fuel-gas system 5 - 38 Oxyhydrogen Welding (OHW) • Form of gas welding once used extensively – Today have limited use • Flame produced by burning two volumes of hydrogen with one volume of oxygen – Temperature of ~ 4,100ºF – Almost invisible • Similar equipment to that used for oxyacetylene welding – Need regulator specifically designed for hydrogen 5 - 39 Oxyhydrogen Welding (OHW) • Relatively low flame temperature – Used principally in welding metals with low melting points – Used extensively in welding of lead • Thicknesses of lead up to 1/4 or 3/8 inch • No deposit of carbon 5 - 40 Flash Arrestors • Generally make of sintered metal alloy • Prevents flame from moving upstream of arrestor • Does not protect torch or tip – Neither does check valve Best way to assure that accidents don’t happen is to follow all safety operating procedures. 5 - 41 Internal View of a Check Valve Prevents the Reverse Flow of Gases Thermadyne Industries, Inc./Victor Equipment Company Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 42 Internal View of a Flashback Arrestor Thermadyne Industries, Inc./Victor Equipment Company Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 5 - 43