Design for Serviceability (DFS) Presentation

advertisement

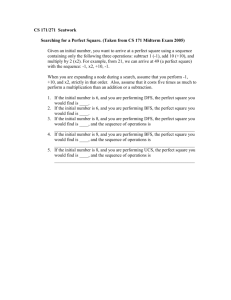

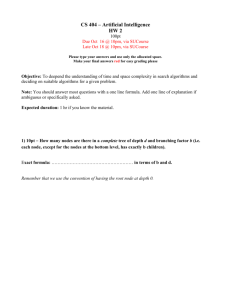

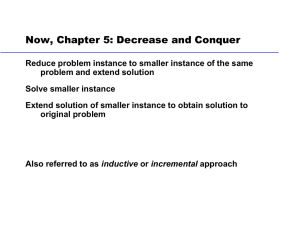

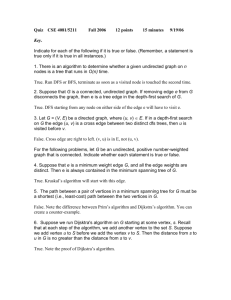

MPD 575 Design for Serviceability Jonathan Weaver 1 • Pg 3 3rd line, "At" should be "at" • Pg 3 4th line from bottom, "Of" should be "of" • Pg 48 "earth" should be "Earth" • Pg 59 "design" should be "designs" • Pg 59 "lead" should be "led" • Pg 63 "engines" should be "engine's" 2 Development History • Originally developed by Cohort 1 team of Henry Brown, David Ogbuaku, and Vince Croom • Critiqued and Improved by Cohort 1 team: Steve Borkes, Larry Liotino, and Dennis Person • Critiqued and Improved by Cohort 2 team: Tom Jones, James Watson, and Doug Schrandt 3 Intro Humor A few days ago a gentleman was having some work done at his local garage. A blonde came in and asked for a seven-hundred-ten. They all looked at each other, and another customer asked, "What is a seven-hundred-ten?" She replied, "You know, the little piece in the middle of the engine, I lost it and need a new one. It had always been there." The mechanic gave the blonde a piece of paper and a pen and asked her to draw what the piece looked like. She drew a circle and in the middle of it wrote 710. He then took her over to another car which had the hood up and asked, "is there a 710 on this car?" She pointed and said, "Of course, its right there." 4 Intro Humor (Cont.) 5 Design for Serviceability(DFS) • • • • • • • • • • • • Introduction to DFS Why DFS? DFS and the Customer Impact of DFS Serviceability Concerns Guidelines for DFS DFS Process Other DFS Needs Useful DFS Data and Tools Software Examples Summary 6 Design for Serviceability (DFS) Introduction "In the Ford Motor Company we emphasize service equal with sales...It has always been our belief that a sale does not complete the transaction between us and the buyer, but establishes a new obligation on us to see that his car gives service... We are as much interested in your economical operation of the car as you are in the economical manufacture of it... This is only good business on our part... If our car gives service, sales will take care of themselves... For that reason we have installed a system of controlled service to take care of all Ford car needs in an economical and improved manner... We wish all users of Ford cars to know what they are entitled to." Henry Ford 7 Design for Serviceability (DFS) Introduction • Service is defined as: – the occupation or function of serving; to perform services for: as to repair or provide maintenance for, to perform any of the business functions auxiliary to production or distribution. Source: Webster’s Dictionary 8 Design for Serviceability (DFS) Introduction • Serviceability, according to Ford Motor Company, is defined as: – The ability to diagnose, remove, replace, replenish, adjust, or repair any component or subsystem, to optimum specification, with relative ease. Source: Ford Motor Company DFIS Manual 9 Design for Serviceability (DFS) Introduction • By extrapolation, Design for Serviceability is defined as: the practice of considering service and serviceability as part of the design process. • The process of optimizing a product for serviceability is fundamentally different from that of optimizing it for ease of initial assembly. 10 Design for Serviceability (DFS) Why DFS? • To achieve and maintain leadership, businesses must satisfy their customer and at the same time control costs, a challenging task. • A great many elements make up customer satisfaction: product cost, performance, styling and quality. • Quality includes not only conformance to specification, measured by fit and function, but also the quality of the vehicle over time, usually measured as life cycle cost. 11 Design for Serviceability (DFS) Why DFS? • Along with these technical elements, products must also be manufactured to create an enjoyable ownership experience to keep customers happy and coming back. • One major obstacle to customer satisfaction is the cost of maintenance and service, and the aggravation they both create. • Warranty is a major cost in the product life cycle, thus both manufacturers and customers are interested in the serviceability of the product. 12 Design for Serviceability (DFS) Why DFS? • Proper application of DFS methods can decrease total life costs and increase the bottom line. • Serviceability must be considered early in the design cycle. • "Serviceability reviews often occur late in the development process when the design is quite firm and changes are costly." (source: Design Theory and Methodology DTM ’91) • 70% of the life cycle costs are committed by the time of concept formulation, rising to 85% by the start of development before any hardware is built. (source: Design for Serviceability Expert System ) 13 Design for Serviceability (DFS) DFS and the Customer - Stakeholders • • • • Distribution System (Dealers) D-I-Y (Do It Yourself) Owners…You!! Manufacturing / Assembly Plants Third-party Service Providers 14 Design for Serviceability (DFS) DFS and the Customer - Buying Motives • A study conducted by Tenneco Corp. to identify customer buying motives found that the number one factor in the buying decision was a well-constructed, high quality product. • Three of the top five buying motives involved quality product service. 15 Design for Serviceability (DFS) DFS and the Customer - Buying Motives • Among the top five buying motives, customers identified: – Quality – Repair work – Repair when promised – Quick service response (source: 1989 ASQC Quality Congress Transactions) 16 Design for Serviceability (DFS) DFS and the Customer - Desires • When it comes to service, customers desire no service at all. • To satisfy customers from a serviceability view, the manufacturer should design for: – Reliability – Minimal maintenance – D-I-Y (Do It Yourself) maintenance 17 Design for Serviceability (DFS) DFS and the Customer - Satisfaction & Loyalty • It cost five times as much to gain one new customer as it does to retain one. • Satisfied customers tell eight to ten others. • Dissatisfied customers tell 16 to 20 others. • Twenty-five percent of the dissatisfied customers may tell as many as 40 other people. (source: Automotive News) 18 Design for Serviceability (DFS) DFS and the Customer - Satisfaction & Loyalty • If service is required, customers expect it to be with relative ease and minimal cost. • To maintain customer satisfaction and loyalty, repair time and cost must be minimized. For the manufacturer this means: – Repairs should be continuously reduced. – Repair time reduction depends on solid diagnostics, ease of access, simplicity and standardization. – The final cost of a repair must be reduced. • Excellent serviceability helps a company develop and maintain customer satisfaction and loyalty. 19 Design for Serviceability (DFS) DFS and the Customer - Satisfaction & Loyalty • Poor serviceability leads to customer dissatisfaction through higher costs and longer repair time resulting in lost sales and market share for the manufacturer. • To maintain customer satisfaction and loyalty, manufacturers should provide a high level of product serviceability. 20 Design for Serviceability (DFS) DFS and the Customer - Satisfaction & Loyalty • Customers expect superior service from major service and repairs to minor adjustments. • The following measured costs have a strong correlation with serviceability: – Operating costs – Scheduled maintenance and repair costs – Unscheduled maintenance and repair costs 21 Design for Serviceability (DFS) DFS and the Customer - Satisfaction & Loyalty Customers look at total cost of ownership. If a product needs repair the owner cares about how often the repair must be done, how long it takes to complete the work (the aggravation factor) as well as how much it costs. – Costs not covered under warranty, or incurred after the warranty expires, increase customer dissatisfaction. – In the automotive industry, estimated life cycle repair costs are three to four times the warranty costs. One of the ratings for used cars in Consumer Digest is the average cost of repairs. A cost index rating shows how each make and model’s repair costs stack up against the competition. 22 Design for Serviceability (DFS) Impact of DFS Design for Serviceability requires considering associated costs of factory corrections of defects, campaigns, litigation, buy-backs, distribution support, and warranty costs. – Reduction in company warranty expenses – Reduction in “customer pay” expenses – Reduction in other hidden costs 23 Design for Serviceability (DFS) Impact of DFS Impact on Manufacturers: • Warranty Improvement • Strengthened Brand Image • Enhanced Residual Vehicle Values • Increased Profitability Impact on Customer: • Improved Satisfaction • Reduced Cost of Repairs • Added Convenience • Improved Diagnostics (faster problem diagnosis leads to faster and less expensive repair) • Reduced Part Pricing • Improved Resale Value 24 Design for Serviceability (DFS) Serviceability Concerns OEM concerns: • Parts Cost: What will be the cost of the replacement parts? • Frequency: How often will the component require service? • Labor Time: How long will the service take? Owner concerns: • Latent Failure: What is the potential for causing a latent failure from the service procedure? • Repeat Repair: What is the potential for having to repair it over? • Performance Level: Will the original vehicle performance level be restored? • Customer Expectation: Will the customer be satisfied with the service? 25 Design for Serviceability (DFS) Serviceability Concerns Technician concerns • Safety: Are there any safety concerns related to service of the component? • Damage: What is the potential for damaging other components during service? • Diagnosis: Are diagnostics required? Can they be performed? • Special Tools: Are special tools necessary? • Reasonableness: Is the service procedure correct for the type of service required and is the procedure straightforward? • Labor Time: How long will the service take? For the technician, all of these are a result of accurate training and well written service reference manuals. 26 Design for Serviceability (DFS) Guidelines for DFS Minimize the number of layers of components. • Results in a reduction in the maximum number of components removed to gain access to a specific part. Design the components that are most likely to fail or need servicing close to the assembly surface. • Results in a cost reduction of the most frequent service operations. Develop a modular product structure. • Whole sub-assemblies may be removed and replaced instead of individual, embedded components. 27 Design for Serviceability (DFS) Guidelines for DFS Minimize the number of connections between sub-assemblies. • The time and complexity to remove and install subassemblies is reduced. Use standard components. • Results in component cost reduction, availability of parts, a reduction in the use of specialty tools, a reduction in the variety of tools needed and reduction of time lost to acquire custom components. Additionally, component characteristics are better predicted. Minimize specialist labor. • Easy problem diagnostics and use of common components allows for servicing by a general technician. Source: U. of Queensland Manufacturing website 28 Design for Serviceability (DFS) DFS Process Determine Initial Serviceability Requirements Define the product serviceability: •Needs •Requirements •Restrictions In addition, what serviceability improvements are needed from the last design? 29 Design for Serviceability (DFS) DFS Process Determine Data Qualifiers for Serviceability • Determine the product’s level of serviceability from past designs and industry benchmarks. • Establish if the product is intended to be serviced by the customer, service centers, the manufacturer or not at all. Components that are regularly serviced by the vehicle owners will have different requirements than those serviced by technicians. 30 Design for Serviceability (DFS) DFS Process Review the Design’s Serviceability A series of checklists should be implemented for serviceability review with the following headings: • Location • Simplification • Standardization • Design for Repair • Life Factors • Diagnostics 31 Design for Serviceability (DFS) DFS Process Review the Design’s Serviceability There are sub-headings, with accompanying questions, under each of the main headings. The sub-headings are as follows: • Location - Accessibility, Obstructions, Orientation, Visibility • Simplification - Minimization, Clustering, Labeling, Intuitive • Standardization - Components and Sub-components, Fasteners and Connectors, Tools • Design for Repair - Ergonomics, Service Aids, Obvious Operation, Safety • Life Factors - Reaction, Mechanical Stress, Environment, Location, Component Retirement • Diagnostics - Indicators, Accessibility, Procedures 32 Design for Serviceability (DFS) DFS Process Location Checklist Accessibility – Is the component layer based on service frequency and user? – Can the component be reached with hands? – Can the component be reached with normal tools? – Can the component be removed from its location? – Can the components be grouped for better serviceability? 33 Design for Serviceability (DFS) DFS Process Location Checklist Obstructions – Do other components have to be removed for visibility, service, or removal? – Is there potential for damage of nearby components in the service process? – Can you offer more space by moving, hiding, or shrinking the component or adjacent component? 34 Design for Serviceability (DFS) DFS Process Location Checklist Orientation – Do the service steps require multiple re-orientations? – Can any fluids be retained in the process? – Will Service expose other parts to contamination? Visibility – Can the component be clearly seen for diagnosis and/or removal/installation? – Does the layout look BIC (Best in Class)? 35 Design for Serviceability (DFS) DFS Process Simplification Checklist Minimization – Have you reduced part count with DFA (Design for Assembly)? – Have you reduced or eliminated user adjustments? Clustering – Is the component located where expected? – Is the component grouped with like functions? 36 Design for Serviceability (DFS) DFS Process Simplification Checklist Labeling – Does the component have clear instructions? – Is the component color coded? Intuitive – Is the disassembly obvious? 37 Design for Serviceability (DFS) DFS Process Standardization Checklist Components and Sub-Components – Can you use an industry standard component or subcomponent? – Can this component be used on other platforms? – Is the component backward/forward compatible? Fasteners and Connectors – Are the fasteners/connectors the same type, size, length? Do they match other assemblies? – Are the fastener orientations the same? 38 Design for Serviceability (DFS) DFS Process Standardization Checklist Tools – Can you service with a minimum of tools? – Can you service without a need for special tools? 39 Design for Serviceability (DFS) DFS Process Standardization Checklist Ergonomics – Can the component be manipulated or removed by hand? – Are the torques within normal user limits? – Have you protected against human-caused failure? 40 Design for Serviceability (DFS) DFS Process Standardization Checklist Service Aids – Have you included guides and assembly aids: locators, pilots, adhesives, sealants, etc. to make assembly easier? – Have you incorporated anti-cross threading? – Have you included adjusting, lifting, pry points? – Can you replace what’s broken? – Must you damage or break components to perform repairs? 41 Design for Serviceability (DFS) DFS Process Design For Repair Checklist Obvious Operation – Can the parts only locate the “right” way? – Is the disassembly/reassembly order mechanically constrained? – Does your design indicate when the repair is correct? Safety – Have you eliminated sharp edges? – Have you guarded against shock hazards? – Have you protected against stored energy - loaded springs, pressurized fluids and explosives? 42 Design for Serviceability (DFS) DFS Process Life Factors Checklist Reaction: – Have you protected against failure from corrosion, galvanic interaction, and reaction with engine and service fluids? Mechanical Stress: – Have you protected against vibration, stress, and thermal expansion? Environment – Have you protected against failure from temperature, ultraviolet, moisture, dirt, and dust? 43 Design for Serviceability (DFS) DFS Process Life Factors Checklist Location – Does the component need to be located for cooling? – Is the component protected from collision damage? Component Retirement – Can the component be designed to be recycled or remanufactured? 44 Design for Serviceability (DFS) DFS Process Diagnostics Checklist Indicators – Have you included maintenance required indicators? – Have you included wear limit, repair, or failure indicators? Accessibility – Does package environment allow diagnostics to be performed with non or limited movement of other components? Procedures – Have you suggested diagnostic procedures? 45 Design for Serviceability (DFS) DFS Process Investigate Opportunities for Improvement • What are our customers telling us they want or need? • What are the existing problems? • What suggestions do our internal experts recommend? • What are we (and our competitors) doing right that we can use? • What are we (and our competitors) doing wrong that we can avoid? 46 Design for Serviceability (DFS) DFS Process Integrate Serviceability into the Design • The first way to improve serviceability is to minimize the need for service. • Use warranty and reliability data to determine failure rates and Pareto ranking to determine priorities. • Use design techniques aimed at increased reliability: Long -life materials and sub-components Reduction of stresses and variations of stresses Design for stiffness Minimize Part Count (DFA/DFM) 47 Design for Serviceability (DFS) Other DFS Needs Other considerations that are not precisely part of that discipline, but have a direct bearing on design for serviceability: • Styling - Styling, craftsmanship and serviceability must be balanced. Innovative designs generate increased need for out-of-the-box thinking to obtain acceptable serviceability. • Appearance - For the consumer who is service conscious, the design of the product must not only be easy to service, it must look easy to service. Many first-time purchases are made on perceptions. 48 Design for Serviceability (DFS) Other DFS Needs • Damageability - Designs must consider damage repair. Expensive and delicate parts must be positioned for protection against damage. The ability to easily disassemble units and only replace damaged elements will reduce labor times and cost to repair. Insurance repair costs are increasingly being used for large purchase evaluations by customers. • Design for Recycleability - With the increasing awareness of our environment, customers are demanding that products be “Earth conscious.” Recycleability is rapidly becoming the law. That means the manufacturer needs to consider using recycled raw materials and increase the ability to reuse or recycle product components that are removed during servicing or maintenance. 49 Design for Serviceability (DFS) Useful DFS Data and Tools Data • • • • • Warranty Data Serviceability Targets Design Manuals TSB (Technical Service Bulletins) TGR/TGW Lists 50 Design for Serviceability (DFS) Useful DFS Data and Tools Tools • • • • • • • R/1000 FMEA DFA/DFM Benchmarking 8D’s (Eight Disciplines) [A Ford Motor Company Process] Reliability/Life Analysis Models (Continuous Improvement Process, etc.) 51 Design for Serviceability (DFS) Software One DFS software product is marketed by Boothroyd Dewhurst, Inc. The same results may be obtained by developing an Excel spread sheet with the proper parameters. • The software provides the user with a series of reports, including a Suggestions for Redesign report which highlights and prioritizes areas in the service task which should be examined for service improvement. • The benefits of conducting a DFS analysis include reduced warranty costs, improved customer satisfaction, and more environmentally sensitive products due to longer life through economical servicing. 52 Design for Serviceability (DFS) Software The benefits of DFS software according to Dr. Peter Dewhurst of Boothroyd Dewhurst, Inc. are: “DFS software provides the type of systematic method that will allow the user to step through the process and look at the service tasks and recognize problems up front.” The methodology for a DFS analysis is: • Identify each service item and choose a disassembly sequence (the reassembly sequence is automatically generated based by the software) • Perform a more detailed analyses of the parts with special service requirements such as corrosion The software renders an analyses on service tasks with estimates of the total disassembly and reassembly time, a serviceability rating and identification of serviceability costs such as labor, operation steps, and part replacement costs. Appliance Manufacturer, Nov. 1993 v41 n11 p69(1) 53 Design for Serviceability (DFS) EXAMPLES 54 Design for Serviceability (DFS) • Financial example for DFS: Independent Tests Prove Toshiba’s Equium Desktops Lead the Industry in Serviceability and Reducing TCO (Total Cost of Ownership) This is mainly attributed to a patent-pending one-touch “Instant Access” door. 55 Design for Serviceability (DFS) • Financial example for DFS: (continued) Excerpts from the article: Equium 7100 series beat the competition in five tests designed to measure business TCO expenses including upgrading memory, upgrading motherboard, replacing hard drive, replacing CD-ROM drive and creating and installing a software pre-install image. 56 Design for Serviceability (DFS) • Financial example for DFS: (continued) Equium 7100 series can reduce PC staffing costs by up to 8.8% or $433 per PC per year. This equates to a total cost savings of $433,000 annually per one thousand seats. Business Wire, July 7, 1999 p0020 57 Design for Serviceability (DFS) Glue as a Serviceability Aid In an article (advertisement in disguise) about the creative use of adhesives, Loctite describes how conformal silicates can replace gaskets in an air pump assembly. The highlights are: A DFA analyses was conducted to demonstrate the savings in time and costs between conventional gaskets and formed-inplace gaskets of silicone. A second analyses was performed to evaluate the formed-inplace gaskets if they were installed in a separate station. 58 Design for Serviceability (DFS) Glue as a Serviceability Aid (continued) The serviceability applicable details of the article are reflected in the data as 13% percent less service time because the gaskets are no longer handled as separate parts but are now in place on the sealed components. An additional feature applicable to DFS is that silicone to silicone seals are more resistant to leaks and environmental degradation than the comparator gasket leading to longer service intervals, both planned and unplanned. Appliance Manufacturer, Nov. 1994 v42 n11 p42(2) 59 Design for Serviceability (DFS) Diesel design in the 1980s Three new diesel engine designs were created in the 1980s with serviceability in mind. This led to a simpler engine design with easier manufacturability in addition to improved serviceability. The new designs were: • Detroit Diesel 60 series engines • Cummins B & C series engines • Caterpillar 3176 series 11.1 and 12.7 liter engines 60 Design for Serviceability (DFS) Diesel design in the 1980s (continued) Detroit Diesel 60 series engine serviceability features: • The engines were electronically controlled which allowed for a diagnostic system that determined the problem quickly and accurately so that the correct part was serviced the first time. • The system self checks each time at engine start to make sure that all sensors, warning lights and electronics are functioning properly. • Electronic control module and sensors are located on one side of the engine compartment. • The hand-held diagnostic reader is reprogrammable for updates and upgrades. 61 Design for Serviceability (DFS) Diesel design in the 1980s (continued) Detroit Diesel 60 series engine serviceability features: • The engines were colored blue to assist in identifying bolts and fluid leaks. The bolts were not painted at all so that the bolt heads would not get gummed up by paint which sometimes prevented sockets from fitting correctly. • The cap screw lengths were varied by at least 10mm to allow for easy identification of a particular bolt. • The 11.1 and 12.7 liter engines have only 450 different parts and are separated by only 8 different part numbers. 62 Design for Serviceability (DFS) Diesel design in the 1980s (continued) Cummins B & C series engine serviceability features: • 600 parts for the B series and 620 parts for the C series achieved through part consolidation. • The water pump inlet and volute, oil cooler, oil pump housing and coolant bypass line are all cast into the engine block. • Designed for the “Backyard mechanic” by eliminating the need for any special tools during servicing. 63 Design for Serviceability (DFS) Diesel design in the 1980s (continued) Caterpillar 3176 series 11.1 and 12.7 liter engine serviceability features: • Part consolidation by commonizing between engines roller and sleeve bearings, O-rings and gaskets. This also minimized the number of special tools required for maintenance. • The gear-type oil pump on the 3116 engine is a separate unit mounted at the front of the engine below the cylinder block. This allows the pump to be removed without removing the front cover or the timing gear train. 64 Design for Serviceability (DFS) Diesel design in the 1980s (continued) Caterpillar 3176 series 11.1 and 12.7 liter engine serviceability features: • Poly-V belts are used with spring loaded belt-tensioners. This allows the belts to be self adjusting and can be installed or removed in minutes. • Gaskets are avoided where ever possible and O-rings are used at all pressure lubrication joints. 65 Design for Serviceability (DFS) New Holland Tractors • Swing-out access door on each side of the hood for routine maintenance. Deere access panels are difficult to remove and tethered to the frame by a cable. • Flip-up hood that gives total access to the entire engine. 66 Design for Serviceability (DFS) New Holland Tractors (Cont.) Swing open instant access to the radiator (Deere requires bolt removal). Self-adjusting belt for A/C and alternator (Deere hard to access; requires adjustment) Fuel filter is vertical (Deere’s is horizontal leading to fuel spills) Common reservoir and screen for transmission and rear axle (Deere uses two) 67 Design for Serviceability (DFS) 1999+ Concorde/Intrepid Powertrain • The 2.7-liter engine oil filter base is integral with the oil pan, preventing spillage during filter changes, and minimizing residual left in the block • The oil filter on the 2.7-liter engines is more accessible than on prior engines • The 2.7-liter engine includes a trough in the valve cover around the oil filler cap nipple that keeps spilled oil (during filling) from running down the side of the block • Increased accessibility to upper bell housing bolts makes transaxle removal easier • A new rear transmission mount simplifies mount replacement and improves transaxle removal • Coil-on-plug ignition eliminates spark plug wires and simplifies tune-ups • Platinum-tipped spark plugs provide 100,000 mile tune-up intervals under normal operating conditions • New exhaust system clamps do not crush pipes together, making pipe separation simple. 68 Design for Serviceability (DFS) 1999+ Concorde/Intrepid (Cont.) Suspension and Steering • New steering tie rod ends make toe adjustment easier • New rear suspension design and fuel tank placement simplifies tank removal • Front stabilizer bar service no longer requires the removal of engine cradle from vehicle • Removal of rear stabilizer bar no longer requires removal of the gas tank • A translucent power steering fluid reservoir allows the fluid level to be checked without removing the cap 69 Design for Serviceability (DFS) 1999+ Concorde/Intrepid (Cont.) Brakes • The modular anti-lock brake system, which places both electronic controls and the valve unit in the same location, is both easier to diagnose and service • New parking brake cable routing along the door sill makes replacement easier Engine Cooling • A carbon seal on the water pump provides life-of-the-vehicle endurance • Long life engine coolant thermostat designed to last 7 years or 100,000 miles • Long-life engine coolant extends the change interval to 5 years or 100,000 miles under normal operating conditions 70 Design for Serviceability (DFS) 1999+ Concorde/Intrepid (Cont.) Body • A new steering column mounting system requires removal of only the steering column cover needs to access the column Diagnostics • Diagnostic communications use the new industry standard J1850 data bus, providing access to on-board diagnostic information by aftermarket scan tools • Odometer readings display briefly when any door is opened to facilitate checking by service attendants 71 Design for Serviceability (DFS) Saturn Serviceability Features • • • • • • • • • Distinctive color-coded dipsticks. Quick-Glance transparent fluid containers. Easy access sparkplugs. Easy replacement air, oil, and transmission filters. Easy access under-hood fuse box. Maintenance-free battery. Self-adjusting accessory belt. Quick-change headlamp bulbs. Handy gas cap holder. 72 Design for Serviceability (DFS) Good example of Heater Core Removal Remove the heater air plenum chamber (18471) assembly as described. 1. Remove the four retaining screws (1) from the heater core cover (18B300) and remove the heater core cover (6) from the heater air plenum chamber assembly. 2. Pull the heater core (18476) assembly from the heater air plenum chamber assembly. Note: There seems to be more steps to this process, removing the hose connections for example, but it is a top removing plan for service which does not require under the car servicing like the next example. 73 Design for Serviceability (DFS) Bad example of Heater Core Removal 1. Remove heater outlet floor duct (18C433) as described. 2. Raise vehicle. Refer to «Section 00-02». 3. Disconnect heater water hoses (18472) from heater core inlet and outlet tubes. Plug heater water hose and cap heater core tubes to prevent coolant loss during removal of heater core (18476). 4. Disconnect vacuum supply hose (black) from vacuum source in engine compartment. 5. Lower vehicle. 6. Disconnect vacuum supply hose (black) from A/C vacuum reservoir tank and bracket (19A566) inside vehicle. 7. Release four retaining tabs, remove two clips and remove heater core cover containing heater core, and vacuum hose (18666) from vehicle. 8. Remove heater dash panel seal (18529) and vacuum hose from heater core cover. 9. Remove retaining screw and heater core mounting bracket from heater core cover. 10.Remove heater core from heater core cover. 11.Remove heater core case seal (18658) from heater core. 12.To install, reverse Removal procedure. 74 Design for Serviceability (DFS) 1975 – 1987 GM HEI Electronic Ignition System Good example of Design for Serviceability 75 Design for Serviceability (DFS) 1975 – 1987 GM HEI Electronic Ignition System 76 Design for Serviceability (DFS) 1977 – 1987 Ford Dura - Spark Electronic Ignition System More complicated Design for Serviceability scheme 77 Design for Serviceability (DFS) Good example of Design for Serviceability Removal 1. Remove approximately one-third of the brake fluid from the brake master cylinder (2140). This will prevent fluid overflow when the caliper piston is pressed into the cylinder bore. 2. Raise and support the vehicle. 3. Remove the wheel and tire assembly. 4. Remove the disc brake pad anti-rattle clip (2B164). 5. Disengage the M-shaped anti-rattle spring from the brake shoes and linings (2001). 6. Remove the two disc brake caliper locating pins (2B296) and the M-shaped anti-rattle spring. Note: Do not discard the shims found behind the brake shoes and linings. Remove the brake shoes and linings and the shims. This service procedure is much less complicated than the following example. 78 Design for Serviceability (DFS) Bad example of Design for Serviceability Removal Refer to the illustration under «Caliper Installation». 1. Remove brake master cylinder cap and check fluid level in brake master cylinder reservoir (2K478). Remove brake fluid until brake master cylinder reservoir is half full. Discard removed fluid. 2. Raise vehicle on hoist. 3. Remove wheel and tire assembly. Use care to avoid damage or interference with front disc brake rotor shield (2K005) or wheel cylinder bleeder screw (2208). 4. Measure run out and rotor thickness. 5. Note: It is not necessary to disconnect hydraulic connections to replace brake shoe and lining (2001). For 15 inch wheels -- Remove front disc brake caliper bolt (2W303) from disc brake caliper (2B120). For 16 inch wheels -- Remove lower brake pin retainer from disc brake caliper. 6. For 15 inch wheels -- rotate disc brake caliper up and away from front disc brake caliper anchor plate (2B292) and front disc brake rotor (1125) pivoting on the disc brake caliper locating pin (2B296). 7. Support the disc brake caliper assembly in a manner that will not stretch or damage the front brake hose (2078). Be sure shoe and linings stay in the front disc brake caliper anchor plate. 8. Remove outer and inner brake shoe and lining assembly from front disc brake caliper anchor plate. 9. Inspect both front disc brake rotor braking surfaces. Minor scoring or buildup of brake shoe and lining material does not require machining or replacement of front disc brake rotor. Remove glaze from both front disc brake rotor braking surfaces by hand-sanding with garnet paper 100A (medium-grit) or aluminum oxide 150-J (medium). 10. Inspect piston boot and caliper pin boots for damage and replace as necessary. 79 Design for Serviceability (DFS) Ignition Switch Removal Good example of DFS 1. 2. 3. 4. 5. Disconnect the battery ground cable. Pull the steering column opening cover off the lower instrument panel (04320). Locate the ignition switch above the driver side knee brace and the steering column opening reinforcement. Disconnect the wiring harness from the ignition switch. Remove the ignition switch screws and the ignition switch. 80 Design for Serviceability (DFS) Ignition Switch Removal Poor example of DFS 1. 2. 3. 4. 5. 6. 7. 8. Disconnect the battery ground cable. Remove the parking brake release handle. Remove the hood latch release handle. Remove the lower instrument panel steering column cover. Remove the instrument panel steering column opening cover reinforcement (04502). Remove the instrument panel steering column opening cover reinforcement. Disconnect the ignition switch electrical connector. Remove the ignition switch. 81 Design for Serviceability (DFS) Oil Fill Cap/Tube LOCATION CHECKLIST • Accessibility, obstruction – Cap and tube access is blocked on three sides. • Visibility – visibility is poor because the tube opening is the same color as the surrounding area when the cap is removed. SIMPLIFICATION CHECKLIST • Clustering – the oil dip stick is not local to this filling tube. • Labeling – cap does have clear labeling • DESIGN FOR REPAIR CHECKLIST • Ergonomics – Cap rotation and oil pour is not easily accomplished. 82 Design for Serviceability (DFS) Oil Filler Tube (continued) LOCATION CHECKLIST • Visibility – visibility is poor because the tube opening is the same color as the surrounding area when the cap is removed. 83 Design for Serviceability (DFS) Oil Filler Tube (continued) LOCATION CHECKLIST •Accessibility, obstruction – Cap and tube access is blocked on three sides. DESIGN FOR REPAIR CHECKLIST •Ergonomics – Cap rotation and oil pour is not easily accomplished. 84 Design for Serviceability (DFS) Oil Filler Tube (continued) DESIGN FOR REPAIR CHECKLIST • Ergonomics – Cap rotation and oil pour is not easily accomplished. Two of three possible positions for oil refill demand an incorrect bottle position. 85 Design for Serviceability (DFS) Oil Filler Tube (continued) Oil refill in correct bottle position but there are no directions on the bottle or on the vehicle to demonstrate this. 86 Design for Serviceability (DFS) Oil Stick LOCATION CHECKLIST •Accessibility, obstruction – Dip stick access is blocked on three sides. •Visibility – visibility is poor because the tube opening is the same color as the surrounding area when the dip stick is removed. SIMPLIFICATION CHECKLIST •Clustering – the oil filling tube is not local to this dip stick. •DESIGN FOR REPAIR CHECKLIST •Ergonomics – Dip stick reinsertion is not easily accomplished. SIMPLIFICATION CHECKLIST •Labeling – handle has clear labeling 87 Design for Serviceability (DFS) Oil Stick (continued) LOCATION CHECKLIST •Visibility – visibility is poor because the tube opening is the same color as the surrounding area when the dip stick is removed. •DESIGN FOR REPAIR CHECKLIST •Ergonomics – Dip stick reinsertion is not easily accomplished. 88 Design for Serviceability (DFS) Oil Filter LOCATION CHECKLIST • Accessibility – Oil filter is not easily accessed for replacement. • Obstruction – Oil filter is accessed only through a narrow slot and degree of rotation with a tool is restricted. • Orientation – Oil filter is oriented for oil drainage but not for the safety of the operator. • Visibility – Engine side threads for the oil filter are not visible. DESIGN FOR REPAIR CHECKLIST • Ergonomics – Surrounding obstructions make filter replacement difficult. • Safety – Oil flow during removal and when the filter is removed is not controllable. 89 Design for Serviceability (DFS) Oil Pan Drain Plug LOCATION CHECKLIST • Accessibility, obstruction – Oil valve is easily accessed. Removal is open for about 180 degrees of turn for a tool. • Visibility – Oil valve is clear and obvious but the addition of color to the head would improve its visibility. DESIGN FOR REPAIR CHECKLIST • Ergonomics – Given that the valve is on the underside of the car, it is relatively easy to access, remove and return to position. • Obvious Operation – The oil valve removal is obvious by the shape of the head. • Safety – The operator has considerable room to work but a warning about hot conditions would be appropriate. 90 Design for Serviceability (DFS) Master Cylinder SIMPLIFICATION CHECKLIST • Clustering – The reservoir is located near the master cylinder • Labeling – The labeling on the cap should be painted. Also, there are too many letters so the character size is quite small making the text hard to read. 91 Design for Serviceability (DFS) Master Cylinder (continued) SIMPLIFICATION CHECKLIST • Labeling – The reservoir has no labeling to tell its function when the cap is removed. 92 Design for Serviceability (DFS) Power Steering Pump Reservoir LOCATION CHECKLIST • Accessibility, obstruction – Power Steering reservoir is easily accessed. Removal is open for about 360 degrees of turn. • Visibility – Power Steering reservoir is clear and obvious. SIMPLIFICATION CHECKLIST Labeling – The reservoir cap has clear, colored labeling. Labeling – There is no label on the reservoir itself. Also, there seems to be no indication as to the correct fluid level, only a warning not to go past it. DESIGN FOR REPAIR CHECKLIST Service aids – The cap is tethered to the bottle. 93 Design for Serviceability (DFS) Coolant & Washer Fluids LOCATION CHECKLIST • Obstruction – The reservoirs have obstructions around them that interfere with fluid pour. They are also located towards the center of the vehicle. • Visibility – The labeling and color of the reservoirs make them distinctive given the color of the surrounding parts. SIMPLIFICATION CHECKLIST • Labeling – The labeling of the reservoir caps are clear and colored. 94 Design for Serviceability (DFS) Coolant & Washer Fluids (continued) SIMPLIFICATION CHECKLIST •Clustering – The two reservoirs are located next to each other, have a similar appearance but contain incompatible fluids. •Labeling – The color and shape similarity of the reservoirs make them indistinctive with the caps removed. The bottles should have labels. 95 Design for Serviceability (DFS) Air Cleaner SIMPLIFICATION CHECKLIST • Clustering – All of the elements for servicing the air system are grouped together. • Labeling – There are no clear labels for any components function. 96 Design for Serviceability (DFS) Air Cleaner (continued) LOCATION CHECKLIST •Accessibility – Assembly attachments are located deep into the vehicle cavity. •Obstruction – The walls of the compartment and the assembly itself acts as obstructions for servicing. •Visibility – There are no colored indications for attachment location and they are located where there is poor light under normal conditions. 97 Design for Serviceability (DFS) Air Cleaner (continued) DESIGN FOR REPAIR CHECKLIST •Ergonomics – Separate, manual fasteners are reduced by slot and tab assembly •Safety – If manual manipulation is required, the assembly is located quite close to sheet metal which may have sharp edges and burrs. 98 Design for Serviceability (DFS) Air Cleaner (continued) LOCATION CHECKLIST • Accessibility, obstruction – the cover is limited in its travel so it is difficult to access the filter itself for removal. 99 Serviceability of Cyclone Grinder • Reducing the part count makes the product easier to service because the tool can be assembled more quickly and the user does not have to keep many parts in inventory for when a grinder needs repair. • Designing parts that can only be assembled in the correct positions and combining small parts into subassemblies facilitates tool maintenance assembly in the plant. http://bits.me.berkeley.edu/mmcs/cyclone/design4service.html 100 Serviceability of Washer • Complete front removes for easier serviceability. • Overall reduction of parts. http://www.warehouseappliance.com/staber.htm 101 Design for Serviceability Aircraft Engines • Removal of an Aircraft Engine Starter with Human Motion • This shows the removal path of a high maintenance starter. • This also shows: – Design for Ergonomics – Design for Assembly http://www.crd.ge.com/esl/cgsp/projects/video/mech/service.html 102 Design for Serviceability Aircraft Engines • Removal Path of an Aircraft Engine Sensor • Film clip shows the access path needed to remove engine sensor. • This also shows: – Design for Assembly – Design for Packaging http://www.crd.ge.com/esl/cgsp/projects/video/mech/service.html 103 Design for Serviceability Automotive • Maintenance Access Solid of a Car Shock Absorber • Film Clip shows access path and clearance to remove shock absorber. • Methods also shows: – Design for Assembly – Design for Ergonomics http://www.crd.ge.com/esl/cgsp/projects/video/mech/service.html 104 Design for Serviceability Related X’s • DFS is most inter-related to: – – – – DFA (Assembly) DFE (Environment) DFE (Ergonomics) DFR (Robustness) 105 Design for Serviceability (DFS) Summary Why - To stay competitive, a company must look at all elements of customer satisfaction. To be profitable, a company must consider the total product life cycle costs. One of the elements that must be considered to accomplish these goals is serviceability. When - 70% of the life cycle costs of a product are committed by the time of concept formulation. A company must incorporate serviceability early in their designs to deliver a product that is efficiently serviceable. How - By following a step-by-step methodology, a company can ensure that it has analyzed the opportunities and best design directions for serviceability incorporation. By using a simple checklists, the basic design features that lead to more serviceable designs may be incorporated. 106 Design for Serviceability (DFS) Summary The Basic Methodology • • • • • Determine Initial Requirement Determine Data Qualifiers Investigate Product Serviceability Investigate Opportunities Integrate Results into the New Design Design Elements • • • • • Location Simplification Standardization Design for Repair Life Factors • Diagnostics 107 Design for Serviceability (DFS) Summary DFS Guidelines • Minimize the number of layers of components • Design the components that are most likely to fail or need servicing close to the assembly surface • Develop a modular product structure • Minimize the number of connections between subassemblies • Use standard components • Minimize specialist labor 108 References • References noted within 109