Interface management process

INTERFACES MANAGEMENT

CRYOMODULES

Vincent HENNION

SYSTEM ENGINEERING ACTIVITIES

TABLE OF CONTENTS

Chapter 01: objectives and constraints (WHY?)

Chapter 02: tasks with associated goals (WHAT?)

Chapter 03: Management process (HOW?)

Chapter 04: Organisation (people) (WHO?)

Chapter 05: tasks planning (WHEN?)

CEA Saclay/ESSI Project| 8 Feb16 | PAGE 2

OBJECTIVES AND CONSTRAINTS

Definition of the external interfaces

Technical interfaces: limit of the responsibility

Functional interfaces: integration success and global performances achievement

Definition of the internal interfaces

Elliptical cavity interfaces

PBS

Unavoidable contraints

International collaboration: multilabs contributions (ESS, CEA, IPNO, LASA,

STFC) for interdependant components required to be very formal

Complex technical system

Multi-site

ESS Specific requirements in terms of massive COTS procurements (pumps, valves…)

CEA Saclay/ESSI Project| 8 Feb16 | PAGE 3

TASKS AND ASSOCIATED GOALS

Mid-Beta Elliptical Cavities

CEA to provide to ESS for LASA interface drawings to be approved by ESS

High-Beta Elliptical Cavities

CEA to provide to ESS for STFC interface drawings to be validated by ESS

Vacuum interfaces: definition under ESS responsibility

Standardization of gaskets?

Standardization of type of valves?

Standardization of type of pumping system equipment?

He cryogenic interfaces

Lessons learnt from demonstrators for design simplification? (flexible parts, number of weldings vs complex geometry…)

RF line interfaces

Handling and Accelerator building interfaces

Alignment interfaces

Electrical interfaces

Test stand interfaces

No interface with Control System

CEA Saclay/ESSI Project| 8 Feb16 | PAGE 4

INTERFACE MANAGEMENT PROCESS

definition

• Technical meetings

• Workshop with ESS partners?

• Preliminary configuration baseline

verification

• Digital Mock-up

• drawings

• lessons learnt from demonstrators

• Tests measurement results

validation

• Interfaces review chaired by ESS

Initial Configuration to be configuration management

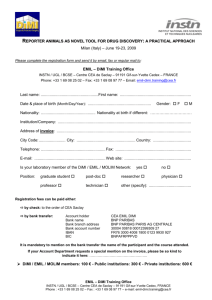

CONTACT PERSONS

CEA Responsibility

Vincent HENNION Interfaces manager

Christelle CLOUE QA manager

Pierre BOSLAND ESS WP Leader

Guillaume DEVANZ ESSI Instrument Scientist

Franck PEAUGER CEA WP Leader

Thierry TRUBLET CEA Deputy WP Leader

Denis

Xavier

GEVAERT CEA contracts manager

HANUS Cryomodule engineering

ESS

Christine DARVE

CEA Saclay/ESSI Project| 8 Feb16 | PAGE 6

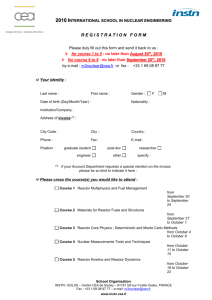

INTERFACE DESCRIPTION FILE

PBS code : XXX

IDF code

X1

Mid-Beta Cavity

Type of interface

Coupler flange

Equipment in interface

RF coupler

Location Institute in interface

CEA ISO5 CR ESS (LASA)

Interface delivery & services at Saclay

ESS : Approve state of the cavity before shipment to CEA

CEA : in charge of the assembly

CEA : control the conformity of the flange

CEA : Specification of the coupler flange on the cavity

Technical characteristics of the flange (type, dimensions tolerances, type and number of screws , material….)

Torque value

CEA: Definition of the cavity interface flange on the coupler

Technical characteristics of coupler interface

Milestone

J1

J2

CEA Saclay/ESSI Project| 8 Feb16 | PAGE 7

INTERFACE DESCRIPTION FILE

Code Title

J1

J2

Project responsible

Ch. Date planed

Mid-Beta Cavity

IDF/X1 coupler flange

Specification of the coupler flange on cavity

CEA coupler

IDF/X1 coupler flange

Definition of the cavity flange on the coupler

CEA

Date validation

CEA Saclay/ESSI Project| 8 Feb16 | PAGE 8

PLANNING

definition: 1st meeting with ESS and CEA on 2016, Feb, 8th

CEA Saclay/ESSI Project| 8 Feb16 | PAGE 9

Thank you for your attention!

QUESTIONS?

| PAGE 10

CEA Saclay/ESSI Project| 8 Feb16

Commissariat à l’énergie atomique et aux énergies alternatives

Centre de Saclay | 91191 Gif-sur-Yvette Cedex

T. +33 (0)1 69 08 xx xx | F. +33 (0)1 69 08 99 89

Etablissement public à caractère industriel et commercial | RCS Paris B 775 685 019

DSM

Irfu