M. M. Robinson High School e-Learning!: Login to the site

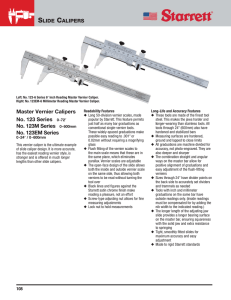

advertisement

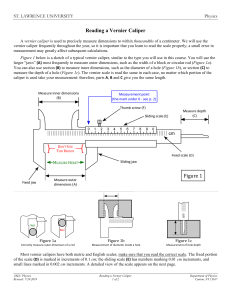

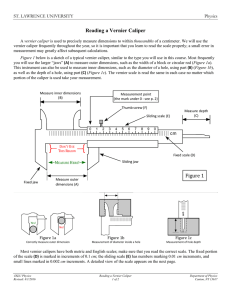

PowerPoint to accompany Technology of Machine Tools 6th Edition Krar • Gill • Smid Vernier Calipers Unit 10 Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 10-2 Objectives • Measure workpieces to within an accuracy of .001 in. using a 25-division inch vernier caliper • Measure workpieces to within an accuracy of .001 in. using a 50-division inch vernier caliper • Measure workpieces to within an accuracy of 0.02 mm using a metric vernier caliper 10-3 Parts of the Vernier Caliper Used to lock readings into place Bar of 25-division vernier scale graduated same as micrometer Manufactured with both 25- and 50-division vernier scales Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 10-4 Measuring a Workpiece • • • • Remove all burrs from workpiece Clean surface to be measured Open jaws enough to pass over work Close jaws against work and lock right-hand clamp screw • Turn adjusting screw until jaws just touch work surface • Lock clamp screw on movable jaw • Read measurement 10-5 Reading the Measurement 1 x 1.000= 1.000 4 x 0.100= .400 1 x 0.050= .050 14 x 0.001= .014 1.464 in. A 50-division inch vernier caliper reading of 1.464 in. Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 10-6 Metric Vernier Caliper • Many have both metric and inch graduations • Parts same as inch vernier • Main scale graduated in millimeters – Every main division numbered, equal to 10 mm – Fifty graduations on sliding scale with every fifth one numbered • 50 graduations occupy same space as 49 graduations on main scale (49 mm) • 1 vernier division = 0.98 mm so difference between 1 main scale division and 1 vernier division = .02 mm 10-7 Reading a Metric Vernier Caliper • Last numbered division on bar to left of vernier scale represents number of millimeters multiplied by 10 • Note how many full graduations showing between this numbered division and zero – Multiply number by 1 mm • Find line on vernier scale that coincides with line on bar and multiply by 0.02 mm • Add for total reading 10-8 Direct-Reading Dial Caliper • Dial indicator, hand attached to pinion, mounted on sliding jaw • Metric: 1 revolution of hand = 2 mm of travel • Inch: 1 revolution = .100 or .200 in. of travel – Depends on manufacturer • Most have narrow sliding blade attached to sliding jaw (and dial) used depth gage 10-9 Digital Electronic Caliper • Can provide readings to resolution of .0005 in. or 0.01 mm at touch of button • No rack, pinion or glass scale • Can connect to Statistical Process Control (SPC) equipment for inspection purposes • Measurements – – – – Inside diameter Outside diameter Step Depth Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display.