SCORE Working Time Demonstration

advertisement

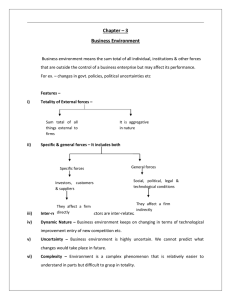

Improving Working Time Arrangements in SMEs An Assessment of the Working Time Demonstration: A research-oriented pilot project in SMEs in Indonesia Jon C. Messenger Team Leader, Working Conditions Group ILO/WORKQUALITY/INWORK Background: Effects of Working Time Arrangements on Firm Performance How working time is organized—called either “working-time arrangements” or “work schedules”—can have important effects on productivity and firm performance Specifically, working time arrangements can (Golden, 2012): Enhance individual and/or organizational productivity, and thus directly restrain unit labour costs of production Improve employee health and well-being and satisfaction with the job or life, without raising current labour costs, and thus reduce costs due to job dissatisfaction & human capital investment Objective of the Working Time Demonstration “Action Research” in SMEs to show how changes in working time arrangements (work schedules) can balance workers’ needs with business requirements, by: Improving firm performance, and Improving workers’ satisfaction with their jobs and their work-life balance Some Key Assumptions 1. Not possible to know a priori what types of working time arrangements (work schedules) are most likely to produce desired results 2. Work with managers and workers to develop customized working time arrangements in each participating enterprise based on their needs 3. Build on key features of the ILO Sustaining Competitive and Responsible Enterprises (SCORE) Programme Participating enterprises completed SCORE training (workplace cooperation) Participating enterprises established Enterprise Improvement Teams (EITs) Implementation (I) Seven SCORE Programme factories in Greater Jakarta, Indonesia volunteered to participate in the Demonstration o Automotive parts and accessories (4) o Medical equipment o Printing and tool bags o Garment manufacturing 5 Implementation (II) 1. Informal focus group discussions conducted with managers and workers in participating enterprises 2. Customized training materials prepared based on the identified needs 3. Training Workshops conducted on designing and managing working time Workshops for enterprises (managers & workers) and SCORE consultants 4. “Kick-off Meetings” conducted with EITs in each participating enterprise 5. EITs in each enterprise developed working time arrangement/schedule SCORE business consultants visited firms monthly to assist the EITs 6. Enterprises implemented the new working time arrangement/schedule Assessment Methodology (I) Qualitative assessment of the processes used by firms to develop and implement working time adjustments, based on site visits Quantitative assessment of key business and worker outcomes • Simple before-and-after comparison of outcomes • Based on survey data collected from managers and selected workers at beginning and end of the Demonstration IMPAQ international, a Washington, DC-based evaluation firm, assessed both the process and outcomes and prepared a report Assessment Methodology (II) Limitations of this Assessment: Small number of firms participating in the Demonstration Participating firms volunteered for the Demonstration (i.e., they were self-selected) The small sample of workers and managers interviewed Observations from Site Visits (I) Some firms tested various small changes in work schedules Starting work 30 minutes earlier (to finish earlier) Starting work 30 minutes later Some firms tested adjusting overtime hours Reducing daily overtime Reducing Saturday hours Some firms tested adjusting break times Providing short breaks (e.g., 10 minutes) One firm enforced a one-hour lunch break However, no firms implemented major changes in working time arrangements (e.g., adding a shift) despite planning to do so Observations from Site Visits (II) Frequent changes in Enterprise Improvement Team (EIT) membership affected design and implementation of new WTAs/work schedules Lack of HR support created serious limitations at some firms Inadequate HR units/functions to support hiring and WTA implementation Frequent turnover in HR staff Heavy customer demands was a major constraint to making working time changes Firms could not reduce daily overtime due to heavy and often unpredictable workloads One firm could not cut Saturday hours because customers insisted on Saturday deliveries Shortages of skilled workers was a constraint for some firms High turnover among skilled workers, due in part to dissatisfaction with long hours Competition for skilled workers made it hard to find enough workers to add an extra shift; this would have enabled these firms to reduce long hours Manager and Worker Surveys IMPAQ International developed two survey instruments: (a) Manager survey and (b) Worker Survey IMPAQ collected Baseline Survey Data (April - May 2013) 20 managers and 21 workers IMPAQ collected Follow-up Survey Data (February – March 2014) 19 managers and 22 workers Manager Survey Responses C11a. How many worker accidents were recorded last year? C11a. How many worker accidents were recorded last year? Baseline Follow-up None 1 5 1-5 accidents 6 2 Manager Survey Responses 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 79% 65% 83% 58% Baseline All respondents Follow-up Repeat Respondents Manager Survey Responses 100 80 85 72 60 40 20 45 45 36 32 21 20 17 0 A B C Baseline 33 21 D Follow-up 21 E Average F G Worker Survey Responses 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 100% 88% 82% 58% Baseline All respondents Follow-up Repeat Respondents Worker Survey Responses 100% 73% 80% 60% 50% 75% 50% 40% 20% 0% Baseline All respondents Follow-up Repeat Respondents Worker Survey Responses 100% 90% 80% 70% 60% 50% 40% 30% 20% 10% 0% 73% 75% 51% 35% Baseline All respondents Follow-up Repeat Respondents Conclusions (I) Few changes in working time arrangements were implemented during the demonstration Efforts to make major changes in work schedules did not succeed due to a variety of obstacles E.g., lack of HR support, inadequate infrastructure, etc. Both managers and workers believed that working time adjustments improve productivity Managers became increasingly aware of the need to measure productivity; however they were unable to measure it correctly While efforts were made to develop and implement new working time arrangements, only small adjustments in work schedules were successful During the project, managers asked for support in measuring productivity SCORE business consultants tried to assist them, but firms were still unable to measure productivity accurately Enterprise profitability did not change as a result of the demonstration There does not appear to be a consistent change in revenue or profitability across enterprises Conclusions (II) The demonstration appears to have reduced the number of accidents at participating firms At follow-up, workers felt substantially more positive about their job and work-life balance than they did at baseline despite few changes in working time arrangements One possible explanation of this finding is that workers appreciated management’s concern about their work-life balance Moreover, workers' involvement in the process of developing new work schedules may have indicated a level of respect from managers that contributed to workers feeling more positive about their job and work-life balance This finding could be interpreted as an effect of worker voice Lessons Learned SMEs have significant limitations in implementing new WTAs/work schedules Limited HR staff and weak HR support Weak (or no) infrastructure to measure the effects of working time changes Other business distractions (e.g., heavy customer demands, inadequate space) The range of WTA options offered to participating SMEs was too broad Some enterprises attempted schedule changes that were not feasible for them Less ambitious changes in work schedules might have been more successful SMEs lack the necessary infrastructure to implement new WTAs/work schedules Firms could benefit from practical tools (manuals, software) to help them: Develop and implement new WTAs/work schedules Measure the effects of WTA/schedule changes on productivity and profitability These tools could enhance development & sustainability of new WTAs/schedules Thank you for your attention! Jon C. Messenger Team Leader, Working Conditions Group ILO/WORKQUALITY/INWORK