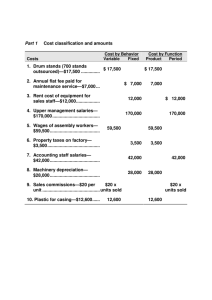

Implementation of TOC

advertisement

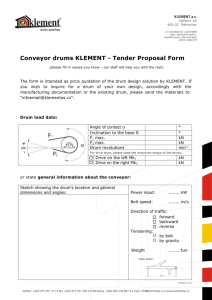

Session 18 Implementation of TOC at Tosoh, SMD Laura Blum Production and Inventory Control Manager 1 Overview • • • • Why we chose Theory of Constraints Overview of Theory of Constraints Implementation Results 2 Before TOC • Manual scheduling using calendars & guesses • Rough understanding of run times • No clear measure of capacity • No ability to forecast upcoming capacity constraints • MRP system – poorly maintained 3 Why We Chose DBR • Deliver product faster and more reliably – Short Product Life Cycles (6-12 months) • Maximize throughput of factory • Better Utilization of Resources • Reduced Finished Goods Inventory – Increased flexibility – Minimize obsolescence 4 Why We Chose DBR (continued) • Minimize batch sizes – Reduced cycle time – Improved responsiveness – Reduced WIP 5 Theory of Constraints • Any manufacturing system has a very limited number of constraints • The constraint limits the output of the entire system • By controlling and maximizing the output of the constraint, you can control and maximize the output of the entire system 6 TOC: Drum-Buffer-Rope • Drum – Another name for constraint or “bottleneck” – Detailed Schedule – Reduce set-ups – Maximize Machine availability • Buffer – WIP to protect against variations in upstream operations – Represents time to resolve problems at upstream operations • Rope – “Pull Signal” – total of upstream processing time and buffer time – Ties drum schedule to customer requirement – Ties material release schedule to drum schedule 7 Steps in TOC • • • • • • • Identify drums Establish buffers Manage buffers Exploit drums Subordinate to the drums Elevate the drum Start over 8 Implementation • The Drum – Scheduling – Identify Constraints – Identify First Day Loads • The Buffer – Proactive Management – Determine the Buffer Size – Non-Drums operate in FIFO mode – Buffer Management – Managing the Exceptions – Identify causes of buffer “holes” 9 Drum Schedules 10 Implementation • Exploit the drums – Work drums continuously – Reduce set-ups – Off-load work to non-drum work centers • Subordinate everything to drum – – – – – Staffing Maintenance Engineering Support Run Non- constraints FIFO Buffer coordinator expedites at non-constraints to meet drum schedules 11 Implementation • Elevate Drum – Increase Capacity – Add Capacity – Process Improvements – Offload • Start Over – Identify new constraint 12 Paradigm Shift Traditional Measure Efficiencies Keep equipment running Focus on product cost TOC Measure Drum Performance and buffer attainment Maximize Throughput Revenue generated per drum time 13 Implementation Process • Change Company Culture – Educate Personnel in DBR/TOC – Eliminate Cost Accounting Based Performance Measures (Productivity, Efficiency, Product Cost, etc.) – It’s O.K. for non-drums to be idle – Company-wide, not just manufacturing 14 Implementation Process (Continued) • • • • Began Manual DBR Purchased software to assist Developed Manufacturing Information Ongoing effort to change company culture 15 Implementation Process (Continued) • Eliminate obstacles to flowing material – – – – – – Raw Material Availability Sense of Urgency in People Process Reliability Equipment Reliability Scrap Batch Processes 16 Achievements • • • • • • Non-Precious Product Sales Delivery Performance Lead Times Finished Goods Inventory WIP Reserves for obsolete inventory + + - 14% 38% 14% 32% 14% 50% 17