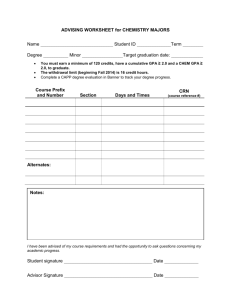

Fracture Mechanics modeling of subsurface crack propagation

advertisement

Analytical Modeling of Surface and Subsurface Initiated Fretting Wear Arnab Ghosh Ph.D. Research Assistant Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 2 Outline • Motivation & Background • Surface Initiated Fretting Wear – Simulation of fretting – Stress based wear model (Damage Mechanics) – Effect of friction, hardness and Young’s modulus • Subsurface Initiated Fretting Wear – – – – Use of Linear Elastic Fracture Mechanics (LEFM) Crack propagation criteria Crack paths and life calculations Effect of friction and normal load on life Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 3 Motivation and Background Cracks caused by alteration of the friction forces acting on surfaces of actual contact (Hirano & Goto, 1967) Intergranular fracture of ball bearing steel due to hydrogen embrittlement (Scott, 1968) Surface Crack Initiation Alternating tensile and compressive stresses induce fatigue crack formation around the regions of surface contact. The direction of propagation of these cracks is clearly associated with the direction of the contact stresses. Cross section of specimen showing surface cracks. (Nishioka & Hirakawa, 1969) Crack formation underneath the wear track of annealed copper (Suh, 1973) Subsurface crack initiation - Ductile fracture initiated by formation of microcracks at interface between precipitates - Subsequent removal of material in fretting wear happens due to delamination (Waterhouse, 1977) Fracture surface showing crack extension by alternating shear (wavy slip region) – (Pelloux, 1970) Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 4 Simulation of Fretting in FEA Partial Slip A 2 dimensional Hertzian line contact with plain strain condition is simulated in FEA to study the stress states at different stages of fretting. Gross Slip Von Misses stress and fretting loops at the interface It can be observed that high contact stresses are observed in the slip regions and therefore, surface damage (wear) can be related to these stresses. Each Voronoi cell is divided into Constant Strain Triangle elements Steel microstructure Voronoi Tessellation FEA mesh 2D Voronoi tessellations incorporate randomness in the microstructure and geometrically simulate the grain morphology observed in reality. Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 5 Stress based Wear Model ENERGY BASED WEAR EQUATION DAMAGE EVOLUTION 𝐹𝑓 = 𝐹𝑠 + 𝐹𝑝 (E Rabinowicz) Fs : Shear Force Fp=Ploughing Force Generalized damage equation: dD dN r 1 D 𝐹𝑓 = 𝑆𝑢𝑠 𝐴𝑟 + 𝐹𝑝 Fp = 0 (for surfaces with similar hardness and roughness) 𝐴𝑟 ≅ 𝐹𝑁 /𝐻 𝐹𝑠 ≅ 𝐹𝑁 𝑆𝑢𝑠 /𝐻 𝜇 = 𝐹𝑠 /𝐹𝑁 ≅ 𝑆𝑢𝑠 /𝐻 (Amonton) 𝑉 ∝ 𝜇𝐹𝑁 𝑠 (Fouvry et al) 𝑆𝑢𝑠 𝐹𝑁 𝑠 𝑉= 𝐸𝐻 m Damage Law derived for Wear equation: 𝒅𝑫 𝑺𝒖𝒔 ∆𝝉 = 𝒅𝑵 𝑬𝑯(𝟏 − 𝑫) ∆𝜏 ∶ (max − min) shear stress 𝑆𝑢𝑠 : Ultimate strength in shear (0.8𝑆𝑢𝑡 ) INTERGRANULAR CRACK PROPAGATION Grain removal (Crack surrounds a grain) D Dc Crack at grain boundary Crack Propagtes along the grain boundary in CCW direction Simulating wear by removing grains at the contact interface Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 6 Wear Propagation Evolution of contact pressure as wear progresses Vw Vwr N Vwo Archard’s Law: VAR k AR FN 4 N H VAR k AR FN 4 N H From the Damage Mechanics model: Vwr VAR kGS FN 4 N H kGS Vwr H FN 4 The coefficient kGS thus obtained is compared to Archard’s wear coefficients found in literature Comparison of wear scars with experiments Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 7 Effect of Coefficient of Friction 2000 1500 1000 0.25 0.5 0.75 1.0 500 0 0 500 1000 Number of Cycles H=4GPa, E=200 GPa 1500 2500 22.928,-4018 30.911,-4812 33.492,-4547.7 33.255,-4504.3 3000 2500 2 2500 3500 9.6586,-4317.2 7.3796,-2516.8 13.379,-4528.9 13.612,-4631.9 3000 2 Wear Volume (m /m) 2 Wear Volume (m /m) 3000 3500 5.1226,-4199.4 8.5199,-5385.9 8.4701,-4716.2 6.7386,-3586 Wear Volume (m /m) 3500 2000 1500 1000 0.25 0.5 0.75 1.0 500 0 0 500 1000 Number of Cycles 2000 1500 1000 0.25 0.5 0.75 1.0 500 1500 H=2.5GPa, E=200 GPa 0 0 500 1000 Number of Cycles 1500 H=1GPa, E=200 GPa 𝑉𝑤 = 𝑉𝑤𝑜 + 𝑉𝑤𝑟 𝑁 H (GPa) E (GPa) 4 200 4 200 4 200 4 200 µ 0.25 0.5 0.75 1 Vwr 5.1226 8.52 8.47 6.7 Vwo V(@10000) k 4199.4 47027 1.14E-02 5385.9 79814 1.89E-02 4716.2 79984 1.88E-02 3586 63414 1.49E-02 A critical value of µ was observed between 0.25 and 0.5 for the mentioned input parameters. Increasing µ beyond 0.5 doesn’t change wear rate considerably. Wear rate vs Coefficient of Friction V@10,000 : Wear Volume after 10000 cycles calculated using the equation Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 8 3500 3000 3000 3000 2500 2 2500 2 Wear Volume (m /m) 3500 Wear Volume (m /m) 3500 2 Wear Volume (m /m) Effect of Hardness 2000 1500 8.5199,-5385.9 14.352,-5734 30.911,-4812 1000 4 GPa 2.5 GPa 1GPa 500 0 0 500 1000 Number of Cycles 1500 µ=0.5, E=200 GPa 2000 8.4701,-4716.2 13.379,-4528.9 33.492,-4547.7 1500 1000 4 GPa 2.5 GPa 1GPa 500 0 0 500 1000 Number of Cycles 1500 2500 2000 1500 1000 4 GPa 2.5 GPa 1GPa 500 0 0 µ=0.75, E=200 GPa H (GPa) E (GPa) 4 200 4 200 4 200 2.5 200 2.5 200 2.5 200 1 200 1 200 1 200 6.7386,-3586 13.612,-4631.9 33.255,-4504.3 500 1000 Number of Cycles µ=1.0, E=200 GPa µ 0.5 0.75 1 0.5 0.75 1 0.5 0.75 1 Vwr 8.52 8.47 6.7 13 13.38 13.61 30.91 33.49 33.255 Vwo V(@10000N) k 5385.9 79814 1.89E-02 4716.2 79984 1.88E-02 3586 63414 1.49E-02 5734 124266 1.81E-02 4529 129271 1.86E-02 4632 131468 1.89E-02 4812 304288 1.72E-02 4547.7 330352 1.86E-02 4504.3 328046 1.85E-02 Wear rate vs Hardness Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 1500 9 Effect of Young’s Modulus 3500 14.352,-5734 8.0862,-2980.9 3000 6.4052,-2362.3 1500 1000 200 GPa 300 GPa 400 GPa 500 0 0 500 1000 Number of Cycles 1500 2500 2 2500 2 2000 30.911,-4812 20.25,-2987.1 16.329,-2414.1 3000 Wear Volume (m /m) Wear Volume (m /m) 2500 2 Wear Volume (m /m) 3000 3500 3500 8.5199,-5385.9 5.2344,-3131.5 4.138,-2451.1 2000 1500 1000 200 GPa 300 GPa 400 GPa 500 0 0 µ=0.5, H=4 GPa 500 1000 Number of Cycles 2000 1500 1000 200 GPa 300 GPa 400 GPa 500 1500 0 0 µ=0.5, H=2.5 GPa H (GPa) E (GPa) 4 200 4 300 4 400 2.5 200 2.5 300 2.5 400 1 200 1 300 1 400 Wear rate vs Young’s Modulus 500 1000 Number of Cycles 1500 µ=0.5, H=1 GPa µ 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 0.5 Vwr 8.52 5.23 4.14 14.35 8.08 6.4 30.9 20.25 16.33 Vwo V(@10000N) k 5385.9 79814 1.89E-02 3131.5 49169 1.16E-02 2451.1 38949 9.20E-03 5734 137766 1.99E-02 2981 77819 1.12E-02 2362.3 61638 8.89E-03 4812 304188 1.72E-02 2987 199513 1.13E-02 2414.1 160886 9.07E-03 It has been shown that for low cycle fatigue wear of dry and smooth contacts , the wear coefficients are of the order of 10-3 to 10-2 (Challen & Oxley, 1986) Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 10 Subsurface Crack Propagation 1600 • • • Linear Elastic Fracture Mechanics is used to propagate subsurface cracks An initial crack of length 5 𝜇𝑚 is created at depth of 10 𝜇𝑚 from the contact surface Alternating shear stress is observed at both the crack tips A mode II fracture mechanism is assumed 1500 LEFT CRACK TIP 1400 xy (MPa) • 1300 1200 RIGHT CRACK TIP 1100 1000 2 2.2 2.4 2.6 2.8 3 3.2 Time (s) 3.4 3.6 3.8 4 Shear stress reversal at the 2 crack tips Detailed view of the Left crack tip Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 Use of Linear Elastic Fracture Mechanics (Mode II) 11 Under compressive load (Hertzian Pressure), Mode I growth is suppressed and Mode II growth is more predominant. Linear Elastic Fracture Mechanics (LEFM) can be used to find the direction of crack growth Check for LEFM assumption The plastic zone size: 𝜎𝑌 CYCLIC PLASTIC ZONE 𝟏 𝑲𝑰𝑪 𝑹𝑷 = 𝟐𝟒𝝅 𝝈∗𝒀 𝟐 = 𝟐. 𝟖𝟖 𝝁𝒎 The crack extension, Δa therefore needs to be a value higher than 𝑅𝑃 𝐾𝐼𝐶 is the fracture toughness and 𝜎𝑌∗ for plane strain is given by: 𝝈𝒀 𝝈∗𝒀 = 𝟏 − 𝟐𝝂 CRACK MONOTONIC PLASTIC ZONE −𝜎𝑌 𝜎𝑌 is the yield stress of the material 52100 steel properties are used: 𝜎𝑌 = 1220 𝑀𝑃𝑎, 𝐾𝐼𝐶 = 18 𝑀𝑃𝑎√𝑚 Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 12 Crack Propagation Direction The radial shear stress at the crack tip is given by: 𝟏 𝜽 𝝉𝒓 = 𝐜𝐨𝐬 𝑲𝟏 𝒔𝒊𝒏𝜽 − 𝑲𝑰𝑰 𝟑𝒄𝒐𝒔𝜽 − 𝟏 Stress Intensity Factors (SIFs) ~ Modified Crack Closure Technique 𝟐 𝟐𝝅𝒓 𝟐 The alternating shear stress is given by 𝚫𝝉𝒓 = 𝟏 𝜽 𝐜𝐨𝐬 𝚫𝑲𝟏 𝒔𝒊𝒏𝜽 − 𝚫𝑲𝑰𝑰 𝟑𝒄𝒐𝒔𝜽 − 𝟏 𝟐 𝟐𝝅𝒓 𝑮𝑰 = 𝟏 𝑭 𝒄 𝒖𝒚𝒂 − 𝒖𝒚𝒃 𝟐𝚫𝒂 𝒚 𝑮𝑰𝑰 = 𝟏 𝑭𝒙𝒄 𝟐𝚫𝒂 𝟐 𝒅𝚫𝝉𝒓 =𝟎 𝒅𝜽 𝒖𝒙𝒂 − 𝒖𝒙𝒃 For plane strain, 𝑲= 𝑮𝑬 𝟏 − 𝝂𝟐 Possible crack paths 𝛥𝑎 Valid for 𝑎 < 0.05, but Crack Tip Opening Displacement is restricted under compressive load and MCCT can be used for higher 𝛥𝑎. In the current model, 𝛥𝑎 = 3𝜇𝑚 The crack propagates in the direction of maximum alternating shear stress Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 13 Crack Tip Mesh Refinement • • • Crack Growth showing adaptive meshing around crack tip The mesh around the crack tip is refined within a radius of 𝑟 > Δ𝑎 A refined mesh around the crack tip is required to – Obtain a more accurate singular stress field – Propagate crack within the refined region. An automatic adaptive mesh refinement is used which moves with the crack tip and maintains the same level of refinement as the crack grows. Rp= 2.88 𝝁𝒎 CYCLIC PLASTIC ZONE REFINED MESH ZONE (r=5 𝝁𝒎) CRACK Crack Tip mesh refinement and the von Mises stress field 𝚫𝐚= 3 𝝁𝒎 Regions around crack tip and crack extension Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 14 Crack Paths and Life 𝝁=0.1 • 10 𝝁𝒎 5 𝝁𝒎 • 𝝁=0.3 𝝁=0.6 • Growth of Initial Crack for different values of Coefficient of Friciton PH=0.5 GPa • • PH=1 GPa PH=2 GPa • Growth of Initial Crack for different values of Hertzian Pressure Initial Crack Dimensions: – Length: 5𝜇m – Depth from Contact Surface: 10 𝜇𝑚 As coefficient of friction increases the span of the crack when it reaches the surface decreases. This is due to decrease in slip with increase in 𝜇. As Hertzian Pressure increases, the span of the crack as it reaches the surface decreases. As the applied load increases, the slip decreases Life is defined as the number of cycles till the crack reaches surface, after which material will be removed. In the current model, life is calculated using the Paris’ Law: 𝒅𝒂 = 𝑪 𝚫𝑲 𝒎 𝒅𝑵 For Martensitic steel, – C=1.36 x 10-10 m/cycle MPa√m – m=2.25 Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 15 Effect of Different variables on Life PH PH=0.5 GPa Approaching partial slip Life decreases 𝜇 PH=1 GPa PH=2 GPa Life vs applied pressure at different values of coefficient of friction • • • • • Life decreases with increase in applied load Effect of 𝜇 at higher loads is negligible Life decreases with increase in 𝜇. Shear Force, Q=𝜇P Life Decreases significantly with increase in Shear Force. 6.5 Log (N) = - 1.39*Log(Q) + 11.3 6 5.5 Log (N) 5 4.5 4 3.5 3 2.5 3.5 4 4.5 5 5.5 6 Log (Q) Life vs Shear Force (Q) Log-log plot of Life vs Shear Force Log(N) = -1.39 Log (Q) +11.3 Mechanical Engineering Tribology Laboratory (METL) November 14, 2013 16 Summary • Surface initiated fretting wear can be modeled by damage mechanics using only standard material properties – – – • Wear rate decreases with increase in Hardness and Young’s modulus Increasing coefficient of friction beyond 0.5 doesn’t impact wear rate The wear coefficients obtained from the model are comparable to Archard’s wear coefficient Sub surface initiated fretting wear can be modeled by Linear Elastic Fracture Mechanics – – – – Alternating shear stress at crack tips drives crack propagation. Crack direction is calculated using a Mode II criteria Crack path is studied for different combinations of variables Paris’s Law is used to calculate the Life Life decreases with increase in applied load and coefficient of friction Future Work • • • • • Incorporate plasticity effects and model hardness in the stress based damage mechanics model Study the effect of grain size and surface roughness Extend the LEFM model to study cracks at different depths from the contact surface Model stress risers (inclusions, void) in the domain and study its effect on crack path Combine Damage Mechanics and LEFM: Subsurface crack initiation using damage mechanics and propagation using LEFM Mechanical Engineering Tribology Laboratory (METL) November 14, 2013