pptx

advertisement

Multi-Product Floorplan Optimization

Framework for Chip Multiprocessors

Marco Escalante1, Andrew B. Kahng2, Michael Kishinevsky1,

Umit Ogras3 and Kambiz Samadi4

1Intel

Corp., 2ECE and CSE, University of California at San Diego

3School of ECEE, Arizona State University, 4Qualcomm Research

SLIP 2015

1

Outline

• Big Picture and Motivation

• Background on Tile-level Floorplanning

• Multi-product Chip Floorplanner

– Generic Formulation

– Choppability constraints for multi-product optimization

• Experimental results

• Conclusions and future work

2

Big picture

• Interconnection networks commonly used in industry

– Servers – Ring and mesh

– Graphics / Throughput computing – mesh

– Clients – Rings

• Cyclic dependency between interconnection network and floorplan

– Interconnection network depends on tile and chip floorplan

– Floorplan depends on interconnection network

core

core

core

core

Cache

Cache

Cache

Cache

core

core

core

core

Cache

Cache

Cache should be wide enough

to support link width

Cache

Cache

Both floorplan and interconnect topology affect Power/Performance/Area

3

Current Examples: Chip-Multiprocessors

• Last level cache (LLC)

• Memory controllers (MC) &

channels

• I/O controller(s)

• QPI controller(s)

• Power control unit (PCU),

• …

PCU

Memory Controller

Core*

C

R

LLC

C

LLC

• Same resources (building

blocks) used for many SKUs

4

C

R

LLC

LLC

C

C

R

LLC

C

MC

* Picture of a low core count system is drawn for illustrative purposes. “Core”

box entails mid-level caches and other common blocks in all cores

Q

P

I

R

LLC

C

R

R

LLC

C

R

LLC

R

LLC

C

C

R

C

MC

P

C

I

e

Multi-product FP optimization

• Different SKUs with varying requirements

– Different number of cores, memory channels, I/O agents

– …yet share the same building blocks

Make the FP choppable to the optimization once and re-use for all

QPI 0

QPI 1

PCIe

QPI

PC

U

QPI

IIO

R3CS

I

R3CS

I

core

Cache

Cache

core

core

Cache

core

Cache

Cache

core

core

Cache

core

Cache

Cache

core

core

Cache

core

Cache

Cache

core

core

Cache

core

Cache

Cache

core

core

Cache

VMSE 0

MC

MC

VMSE

1/2

IV Town – 15 cores

5

QPI 2

MC

MC

VMS

E

3

Intel Xeon Server processor Haswell

had 27 different SKUs, with number of

cores ranging from 4 to 18

Overview of Approach

• Goal: Develop an efficient and robust floorplan optimization

framework for server products

• Involves floorplanning at two levels of hierarchy:

– (1) tile-level, ~10-20 resources

– (2) chip-level, many tiles (> 20 tiles)

• Tile-level FP considers the physical constraints

due to interconnect

• Chip-level FP addresses choppability constraints by

simultaneously optimizing the FP across product classes

6

Tile Floorplanning

• Objective: Minimize area

• Subject to:

– Global routing constraints

– NoC link width

• Major resources

– Core, LLC and MLC caches, Core-MLC interface, LLC/MLC - Ring

interface, snoop filter, etc.

– Resources can be both hard or soft

– Hard blocks can rotate 90°

• Approach: Mixed-integer linear programming (MILP)

• Since tile level FP is not the focus of the paper, only major

distinct properties will be mentioned

Reference: S. Sutanthavibul, E. Shragowitz and J. B. Rosen, “An Analytical Approach to Floorplan Design and

Optimization”, IEEE Trans. on CAD, 10(6), 1991, pp. 761-769.

7

Constraints Imposed by Chip FP

• Routing constraint: Block i and j should not overlap in X and Y directions

j

j

XXX

i

j

CORE

j

XXX

XXX

Router

• Adjacency constraint:

Block i and j should be adjacent

XXX

i

i

j

i

j

i

8

Outline

• Motivation and Big Picture

• Background on Tile-level Floorplanner

• Multi-product Chip Floorplanner

– Generic Formulation

– Choppability constraints for multi-product optimization

• Experimental results

• Conclusions and future work

9

Chip Level Floorplan Overview

• Floorplans of each class can be easily derived through

chopping operation

• Differences with respect to tile floorplan

– Overlap constraints are met by default

– Integer linear programming formulation

– Simultaneous floorplan optimization across multiple product classes

P2

P3

Row 1

MC

Core

MC

MC

Core

Row 0

Core

Core

Core

Core

Core

1

2

0

1

MC

Core

0

1

Chopped

P1

y

Column 0

x

10

2

Chopped

2

Chopped

Preliminaries and Notations

• We use 1-hot binary variables uij such that

– uij = 1 means the cell (i,j) is occupied

– uij = 0 means the cell (i,j) is empty

(1,0)

(1,1)

(0,0)

(0,1)

FP: S0

• We need to extend the definition to multiple floorplans

– usij represents the cell (i,j) in FP “s”

– Multiple types of cells, Core, Memory Controller (MC), Empty

– usij0 means an empty cell at (i,j) in FP “s”

– usij1 means a CORE at cell (i,j) in FP “s”

– usij2 means an MC at cell (i,j) in FP “s”

(1,0)

(1,1)

(0,0)

(0,1)

FP: S1

– Our formulation can consider k resource types

• Example at the right hand side

– u0001 (Core), u0011 (Core)

– u0101 (Core), u0112 (MC)

(1,1)

(0,0)

(0,1)

FP: S2

Core

11

(1,0)

MC

Empty

Generic Problem Formulation

• GOAL: to find {usijk}’s to

• Minimize sum of half-perimeter of all products

(1,0)

(1,1)

(0,0)

(0,1)

FP: S0

(1,0)

(1,1)

(0,0)

(0,1)

• Constraints on number of resources

FP: S1

– Each tile can be occupied by only one type of resource

– Each product has a specified number of instances of each resource

• Monotonicity constraints: Suppose, product i can be chopped to j

(1,0)

(1,1)

(0,0)

(0,1)

FP: S2

MC

Core

12

Empty

Choppability

• Solution = Finding {usijk}’s

• Example at right hand sice

(1,1)

(0,0)

(0,1)

FP: S0

– {u0000 , u0001 } = {0,1} (Core), {u0010 , u0011 } = {0,1} (Core)

– {u0100 , u0101 } = {0,1} (Core), {u0110 , u0111 } = {1,0} (MC)

– {u1000 , u1001 } = {0,0} (Empty), {u1010 , u1011 } = {0,1} (Core)

– {u1100 , u1101 } = {0,0} (Empty), {u1110 , u1111 } = {1,0} (MC)

(1,0)

(1,1)

(0,0)

(0,1)

FP: S1

– {u2000 , u2001 } = {0,0} (Empty), {u2010 , u2011 } = {0,1} (Core)

– {u2100 , u2101 } = {0,0} (Empty), {u2110 , u2111 } = {0,0} (Empty)

Chop the box = Cores are converted to empty

Chopping a cell means Core or MC converted to

Empty

(1,0)

(1,1)

(0,0)

(0,1)

FP: S2

Core

13

(1,0)

MC

Empty

Core/MC Count Constraints

• Assume

– NsCore = Number of cores in FP “s”

– NsMC = Number of MCs in FP “s”

s

s

u

N

ij 1 Core , for s 0,1,2

j

s

s

u

N

ij 2 MC , for s 0,1,2

i

(0,0)

(0,1)

(1,0)

(1,1)

(0,0)

(0,1)

FP: S1

j

usij2 = 1 only if there is an MC in the cell

(1,0)

(1,1)

(0,0)

(0,1)

FP: S2

usij1 = 1 only if there is an Core in the cell

Core

14

(1,1)

FP: S0

• Example: N0Core = 3, N1Core = 1, N2Core = 1, N0HA = 1, …

i

(1,0)

MC

Empty

Height and Width Computations

• To express area, we need a way of representing height

and width, but we will have “s” heights and widths

• For each product class i

Shows that

row r is used

i

1, if

u

rck 1

0 r R 1 1 k K

i, c used ci

0, otherwise

Shows that

column c is used

i

used

r

0 r R 1

i W i w

i

used

c

(0,0)

(0,1)

(1,0)

(1,1)

(0,0)

(0,1)

FP: S1

(1,0)

(1,1)

(0,0)

(0,1)

FP: S2

0 r R 1

Core

15

(1,1)

FP: S0

i

1, if u rck

1

i

0 c C 1 1 k K

i, r used r

0, otherwise

i H i h

(1,0)

MC

Empty

Additional Placement Constraints

• Sources at the boundaries

– Memory controller channels and I/O controllers

• Contiguous tiles

• Adjacency constraints

MCh

MCh

MCh

MC MC

MCh

I/O

I/O

I/O

MCh

MC MC

MCh

I/O

MCh

MCh

MCh

I/O

MCh

MCh

I/O

MCh

MCh

MCh

MCh

MCh

I/O

MCh

I/O

I/O

I/O

MCh

16

MCh

MCh

MCh

MCh

Power- / Performance-Driven DSE

• We allow the number of core and memory controllers for each

product to vary in a given range given target design thermal power

• We add constraints on maximum number of memory controllers in a

given row or column

17

Outline

• Motivation and Big Picture

• Background on Tile-level floorplanning

• Multi-product Chip Floorplanner

– Generic Formulation

– Choppability constraints for multi-product optimization

• Experimental results

• Conclusions and future work

18

Developed Infrastructure

• Read a floorplan description file

• Generate corresponding integer

linear programming formulation that

is fed into CPLEX

• Solutions are written into an ascii file

describing final floorplans of all the

product classes

• The final floorplan description of each

product class is printed as a PDF file

# <#rows> × <#columns>

Biggest product grid size: 6 × 6

N_C_0: 26

N_H_0: 4

N_C_1: 18

N_H_1: 2

# max-k constraint on HAs

MC top: 1

MC bottom: 2

MC left: 1

MC right: 1

# Tile width and height information

Tile width: 2

Tile height: 1

Multi-Product FP Description File

19

Chopping with Four Product Classes

• S0 = 34 cores, 8 MCs S1 = 26 cores, 4 MCs

• S2 = 18 cores, 2 MCs S3 = 10 cores, 2 MCs

20

MC

MC

Core

Core

Core

MC

Empty

MC

Core

Core

Core

Core

Core

Empty

MC

Core

Core

Core

Core

Core

Empty

Core

Core

Core

Core

Core

Core

Empty

Core

Core

Core

Core

Core

Core

Empty

Core

Core

Core

Core

Core

Core

Empty

MC

Core

Core

MC

Core

MC

Empty

Chopping with Four Product Classes

• S1 = 26 cores, 4 MCs S2 = 18 cores, 2 MCs

21

MC

Core

Core

Core

Core

Core

Core

MC

MC

Core

Core

Core

Core

Core

Core

Core

MC

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Chopping with Four Product Classes

• S2 = 18 cores, 2 MCs S3 = 10 cores, 2 MCs

22

MC

Core

Core

Core

Core

Core

MC

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Core

Results with Memory Controller Channels

• S1 = 36 cores, 8 MCs, 8 MChs

S2 = 27 cores, 6 MCs, 6 MChs

MCH8

E

MCH7

MCH6

MCH5

E

MCH2

E

MC

E

MC

E

MC

E

MC

C

C

C

C

C

C

C

C

C

C

C

C

C

C

MC

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

E

MC

C

MCH3

23

C

C

E

MC

C

MCH1

MC

MCH4

I/O

Results with Memory Controller Channels

• S2 = 27 cores, 6 MCs, 6 MChs

S3 = 18 cores, 4 MCs, 4 MChs

MCH2

E

MCH1

24

MCH3

MCH5

MCH4

MC

E

MC

MC

MC

C

C

C

C

C

C

C

C

C

C

E

C

C

C

C

C

C

C

C

C

C

C

C

C

C

MC

C

C

C

MC

E

MCH6

I/O

Conclusions & Future works

• Simultaneous floorplan optimization framework for CMPs

across multiple products

• We define the concept of a choppable floorplan

– Enables us to easily derive the floorplan of smaller products

from those of larger

• Finding choppable floorplans across multiple products to

reduce re-design costs and shortens time-to-market

• Future challenges

– Joint tile and chip level floorplanning

– Reducing the white space when

25

26

Results with Memory Controller Channels

• S1 = 36 cores, 8 MCs, 8 MChs

S2 = 27 cores, 6 MCs, 6 MChs

S3 = 18 cores, 4 MCs, 4 MChs

27

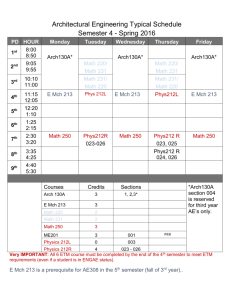

Test Case

# Binary

Variables

# Constraints

CPU

Runtime (s)

1

595

3014

687

2

896

6204

4744

3

1089

7218

14936

Different Grid Size

MC

MC

MC

MC

MC

MC

MC

• Grid size is 6 x 6

• Total number of tiles = 30

• Tile height = 1, Tile width = 2

MC

28

• Enables exploration of different

tile aspect ratios

Power- / Performance-Driven DSE (2)

• We consider different width and height values for different resource types

29

Tile Floorplan Examples

XXX

Logic

MISC

XXX

Pipeline Stages

CORE

Out.

Buffer

XXX

Router

XXX

XXX

IDI

Interface

XXX

XXX

Sample Core Floorplan

30

Sample FP for Router &Cache

Controller

Developed Infrastructure

• Read a floorplan description file

• Generate corresponding mixedinteger programming

formulation that is fed into

CPLEX

• Solutions are written into an

ascii file describing final

floorplan

• The final floorplan description is

printed as a PDF file at the end

# <block name> <area> <minAR> <maxAR> <rotation>

BEGIN FP DESCRIPTION

X1 A1 minAR1 maxAR1 0

X2 A2 minAR2 maxAR2 1

X3 A3 minAR3 maxAR3 1

X4 A4 minAR4 maxAR4 0

END FP DESCRIPTION

# <Block 1> <Block 2> <nonoverlapping constraint>

BEGIN OVERLAP CONSTRAINTS

X2 X4 3

END OVERLAP CONSTRAINTS

#<Block 1> <Block 2>

BEGIN ADJACENCY INFO

X3 X4

END ADJACENCY INFO

Floorplan Description File

31