ppt

CREEP TEST

EXPERIMENT # 6

Instructor: M.Yaqub

WHAT IS CREEP

All materials under constant stress and temperature will exhibit an increase of strain with time called creep.

Creep is strain with time at constant load and temperature (time dependent strain).

Metals usually creep at temperature above

0.3 to 0.4 Tm, where Tm is the absolute melting temperature of the metal.

TEMPERATURE FOR CREEP

Most metals have creep at high temperature since melting temperature of metals are usually high.

For example, carbon steel starts creep above 500 0 C and Aluminum above 100

0 C.

Lead is soft metal and can creep at room temperature therefore in lab, we will use lead at a test metal.

HOW TEST IS PERFORM

Since metals usually creep at high temperature, the actual test is perform in a furnace as shown in the following figure.

WHERE CREEP IS IMPORTANT

When a metal is subjected to high temperature, the creep is an important design consideration.

In many mechanical application, like turbine blades, boiler, reactors, engine, a designer must consider the creep.

CREEP TEST CURVE

CREEP CURVE

ELASTIC STRAIN is the strain produce due to applied tensile load.

FIRST STAGE (Primary creep) in this region, the rate of creep ( ) decreases with time.

t

SECOND STAGE (Secondary creep) in this zone, the creep rate is constant, therefore the curve is linear. The slope of the line gives the creep rate. Usually, the end of this region is taken as the service life for a metal.

CREEP CURVE (Continue)

Tertiary Creep in this zone, strain increases rapidly, micro cracks appears, and finally metal fails.

CREEP DEPENDS UPON STRESS &

TEMPERATURE

CREEP RATE IN SECONDARY

ZONE

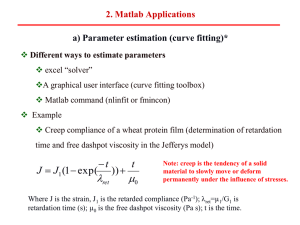

Since creep rate is constant (independent of time) in secondary creep zone, it can be obtained from the following equation.

d

dt

.

K

n exp (

Q

RT

)

CREEP RATE IN SECONDARY

ZONE (CONTINUE)

Where K and n are constant and depends on metal.

Q is the activation energy of the metal in

J/mole. For lead Q = 120,000 J/mole.

R is universal gas constant, 8.31 J/mole-K

Sigma is applied stress and

T is absolute temperature.

CREEP DATA

A Number of sample is tested and the data is plotted as shown in the next slide.

Stress on the Y-Axis and Rupture life on the X-Axis.

Log-Log scale is used for the curve.

This curve is called Stress-rupture-curve.

SRESS RUPTURE CURE

EQUATION OF CREEP RATE IN

SECONDARY ZONE

Test the 4 samples at different load and plot the creep curve for these test.

Gate the creep rate for from the each curve. Now you have 4 stress and corresponding 4 creep rate.

In equation d

dt

.

K

n exp (

Q

RT

)

EQUATION (CONTINUE)

Q, R and T are constant. Therefore get the value of exp(-Q/RT) and say this as A.

Now equation become .

A K

n

Since A and K both are constant, B=AK

.

B

n

EQUATION (CONTINUE)

Since we have 4 points for creep rate and stress, we can plot this equation as creep rate on Y-Axis and Stress on X-Axis. Use excel to plot the point and then fit a power curve. Choose option to display equation.

The power of stress will be “n” and constant will be B.

Get K by using K=B/A

LAB REPORT

Plot the strain as a function of time for each test and calculate the steady state creep rate for each combination of load and temperature.

List the rupture life for all test in one table as function of stress and temperature.

Plot the creep rupture data as explain in lab.

LAB REPORT (Continue)

Estimate n and K by plotting creep rate verses stress as explain in lab.

Use the table available on WebCT to show your results.

Attached 3 graphs with the lab report, graph one having 4 creep curves for the test, graph 2, rupture life curve, graph 3 for n and K.