Spray Booth Operations

advertisement

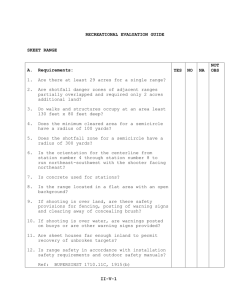

Spray Finishing Operations/Spray Booth March 9, 2009 OSHA Section 5(a)(1) of the OSH Act, often referred to as the General Duty Clause, requires employers to "furnish to each of his/her employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm to his/her employees". Section 5(a)(2) requires employers to "comply with occupational safety and health standards promulgated under this Act". Effect of Lighting……… Proper lighting (bright & fluorescent) along with light color painted walls in the Spray Paint room so that workers/students can see better when spray painting. Selection of Respirators Employer must select and provide an appropriate respirator based on the respiratory hazards to which the worker is exposed and the factors that affect respirator performance and reliability. A pressure gauge that indicates airflow outside the booth will make it easier for instructors to determine when to replace the booths air filters. CLEAN FILTERS Replacing clogged air filters keeps the paint booth’s ventilation system working efficiently to remove paint and solvent mists, protecting the painter and others from overexposure to potentially hazardous substances and decreasing the risk of fire due to flammable vapors. SPRAYING APPLICATIONS A spray application is also particularly hazardous because it creates fine droplets of the fluid, making the fluid more ignitable than when it is applied with a brush. FOLLOW GOOD HOUSEKEEPING Combustible cardboard boxes should not be stored in the booth and filters are not stored properly. STORED CHEMICALS Store only the required amount(s) of flammable liquid for one classes usage at the spraying area. Liquids need to be contained to tight fitting safety containers and labeled properly. Any bulk storage should be stored in a separate storage facility on site or outside the school. The larger the amount stored and used, the greater the potential for improper handling and/or spillage. ERGONOMICS IN THE BOOTH CHECK POINTS Are No smoking signs conspicuously posted. Ref: 1910.107(g)(7) Is the electrical equipment in an electrostatic hand spraying area interlocked with the ventilation system so that it cannot be turned on unless the ventilation fans are operating? Ref: 1910.107(I)(8) Are automatic sprinkler heads located so as to provide water distribution throughout the spray booth? Ref: 1910.107(f)(1) Are fire extinguishers installed near all spraying areas? Ref: 1910.107(f)(4) Is all residue, scrapings, and debris contaminated with residue immediately removed from the premises and properly disposed of? Ref:1910.107(g)(3) Are approved metal waste cans provided whenever rags or waste are impregnated with finishing material and are rags and waste deposit in them immediately after use? Ref:1910.107(g)(3) CHECK POINTS II Are freshly sprayed articles dried only in spaces provided with adequate ventilation? Ref: 1910.107(d)(12) Is mechanical ventilation being operated during all spraying operations and for a sufficient time afterward to allow vapors to be exhausted? Ref:1910.107(d)(2) Does the quantity of flammable or combustible liquids that are kept in the vicinity of spraying operations exceed a supply needed for one shift? Ref: 1910.107(e)(2) Is a visible gauge, audible alarm, or pressure-activated device installed to ensure that the required air velocity is maintained? Ref:1910.107(b)(5)(i) Are only fixed lighting units used as a source of illumination? Ref: 1910.107(b)(10) Are spray booths installed so that there is a clear space of not less than 3 feet on all sides that is kept clear of combustibles? Ref: 1910.107(b)(9) AVOIDANCE OF AIRBORNE CONTAMINENTS A properly working ventilation system will allow the avoidance of time it takes to put on the full body protection & respirators. Ventilation will prevent skin absorption of hazardous substances and inhalation of fumes, mists or vapors from paints or solvents. IN SUMMARY: Have sufficient air flow to assure that the sprayed particles are drawn into the filter system. Be able to filter almost 100% of the particles over 10 microns to assure a clean environment. Have a carbon-type filter, preferably of activated carbon granules, to filter odors. TO ENSURE SAFE & EFFICIENT OPERATION OF THE BOOTH: INSPECT FILTERS MONTHLY. REPLACE FILTERS AS NEEDED. RECORD ANY ACTIONS TAKEN ON A MONTHLY LOG. INITIAL ALL LOG ENTIRES. **** ABOUT EVERY 90 SURFACE SPRAY APPLICATIONS A FILTER WILL NEED TO BE CHANGED.