Miesho Hadush

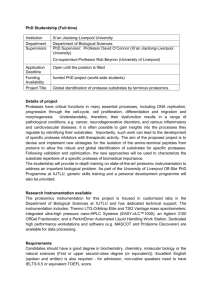

advertisement