ELG 4152 MODERN CONTROL SYSTEM PROJECT

advertisement

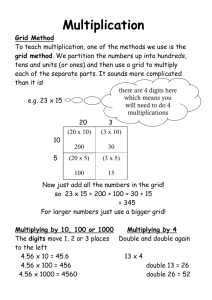

ELG 4152 MODERN CONTROL SYSTEM PROJECT Predictive Feed forward Control for a Hydroelectric Plant by Amirul Bhuiya Norman Escobar Omar Faroque Hung Pham for Professor: Riadh Habash TA: Fouad F. Khalil March 28, 2007 Introduction The purpose for this project is to replicate the work done by Dewi Jones and Sa’ad Mansoor in their paper “Predictive Feedforward Control for a Hydroelectric Plant”, IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 12, NO. 6, NOVEMBER 2004 Their work consisted of simulating the Dinorwig hydroelectric plant in the U.K. and improving its performance by designing a feed forward loop to better respond to frequency variations on the electrical grid. Their design allowed them to improve the system response time by up to 3 seconds depending on the operating point of the hydroelectric plant and the load on the system. Introduction The following references were used in the development of our project: D.I. Jones, “Dynamic system parameters for the National Grid”, IEE Proc.-Gener. Transm. Distrib., Vol. 152, No. 1, January 2005 In this paper Dr. Jones developed a generic model of the National grid Dewi Jones, “Estimation of Power System Parameters”, IEEE TRANSACTIONS ON POWER SYSTEMS, VOL. 19, NO. 4, NOVEMBER 2004. In this paper Dr. Jones developed the parameters for estimating the low order dynamic model of the U.K. power system. German Ardul Mu˜noz-Hern´andez,Dewi Jones, “MIMO Generalized Predictive Control for a Hydroelectric Power Station”, IEEE TRANSACTIONS ON ENERGY CONVERSION, VOL. 21, NO. 4, DECEMBER 2006. In this paper Dr. Ardul applies generalized predictive control to a multivariable model of the Dinorwig power plant. Dewi Jones and Sa’ad Mansoor, “Predictive Feedforward Control for a Hydroelectric Plant”, IEEE TRANSACTIONS ON CONTROL SYSTEMS TECHNOLOGY, VOL. 12, NO. 6, NOVEMBER 2004 In this paper the authors use a feed-forward model to improve the Dinorwig power plant. Sa'ad Mansoor , Thesis "Behaviour and Operation of Pumped Storage Hydro Plants” University of Wales, Bangor, School of Informatics, July 2000. In this thesis Dr. Mansoor developed a model of the Dinorwing power plant. METHODOLOGY APPLIED PROJECT SELECTION FROM IEEE PAPER PAPER RESEARCH EQUATION/MATERIAL ANALYSIS DEVELOPMENT OF BASIC MODEL DEVELOPMENT OF GUI AND TEST SCRIPTS IMPLEMENTATION AND TESTING ANALYSIS OF RESULTS Work Distribution Amirul Bhuiya: Research power plant modeling, select most appropriate model to use and develop proper plant parameters for model implementation Norman Escobar: Implement the system model, the GUI interface and perform related tests using MATLAB and its Simulink and GUIDE toolboxes Omar Faroque: Research a viable grid model, develop and simplify for implementation Hung Pham: Research feed forward systems, develop a feed forward loop to be incorporated into the system model. Each member wrote the corresponding sections in the report and in the development of the presentation. General Background Power Plant DAM Water Generator Transformer Turbine sinning by water flow General Background Water Outlet Water Entrance From Tunnel General Background Dinorwig Electric Generator General Background LV/Secondary side HV/ Primary Side Breather Oil Tank 10MVA Oil Filled Power Transformer General Background Power Grid • The power grid consists of many interconnected power generating stations • Grid circuit load is shared by interconnected power station. • Interconnected power generating stations have to maintain identical Voltage, Phase difference, and Frequency with each other. General Background CB Power Generation Plant 11KV Circuit Breaker C O N S X-former CB Power Generation Plant 11KV Circuit Breaker Transmission Line Consumer Consumer X-former 220KV Circuit Breaker 220KV Circuit Breaker CB X-former Consumer CB Power Grid X-former General Background What causes grid frequency variations? 1. 2. Load variation on the GRID overloads the generators causing their rotation (RPM) to slow down. Lightning creates tremendously high voltages on the Transmission lines with unknown frequencies producing resonant frequencies on the HT line.. Why the need to maintain a constant grid frequency? 1. 2. Frequency variations can damage or disrupt sensitive electronic equipment. Motors, variable speed drives, switching power supplies etc… rely on constant frequency. Frequency deviation to power demand relationship Freq. Deviation Power Demand MODEL DEVELOPMENT Model of Hydroelectric Plant and Electric Grid MODEL DEVELOPMENT PI Controller Guide Vane Servo model MODEL DEVELOPMENT Hydrodynamic model Turbine/Generator MODEL DEVELOPMENT Grid Feedback MODEL DEVELOPMENT Feed forward model FEED FORWARD MODEL Required Feed Forward Transfer Function = Inverse of Gp (According a paper propose by G. C. Goodwin) RESULTS GUI developed to perform tests on system model RESULTS • The GUI was designed to control the turbine/generator parameters • It provides control of the amount of generators running at any given time • It allows the addition of disturbance that models the grid power demand change • It allows control of feed forward and feedback loops to test performance RESULTS • Simulation of system with one generator running, standard turbine/generator parameters and no grid disturbance with feedback only RESULTS • Simulation of system with all generators running, standard turbine/generator parameters, 15MW grid disturbance, feedback and feed forward enabled RESULTS # of Generators Response time (s) With Feedback only With Feed Forward With Disturbance 1 2.24 2.24 2.27 2 3.36 3.36 3.3 3 4.43 4.43 4.12 4 5.44 5.44 5.42 5 6.36 6.36 5.5 6 7.22 7.22 5.9 RESULTS Response time (s) With Feedback only With Feed Forward With Disturbance Normal Operation 3.15 3.15 0 High Load 9.85 9.85 0 RESULTS Normal Operation with grid incorporated RESULTS High Demand with grid incorporated Conclusion • • • • The objective of this project was to simulate the hydroelectric plant model by Dewi Jones and Sa’ad Mansoor which incorporated a feed forward path in an existing feedback control system. Here, we have successfully simulated the idea behind the feed forward control system of 6 hydro power generator. As the results indicate, with feedback alone, the system is stable and works within requirements and specifications. However, the electrical power response to demand variations is very important with respect to delivery time and frequency variations (every second counts). This is where the feed forward theory comes into the design. For this particular control system, feedback improved the steady state error, the settling time, the system’s overall stability, and the system’s overshoot but not the system’s delivery time (when the power is actually being deliver to the consumer). The clear advantages of feed forward theory for this particular system are: 1. Improve delivery time 2. Cheap to implement into existing system (avoiding a new design from scratch) The disadvantage of this particular feed forward model is that every new Grid (city) needs a new feed forward path because different cities have different load or demand characteristics. The main problem that we encounter during the investigating of this project is the simulation of the more practical feed forward design propose by the paper. This is due the fact that we do not have the exact parameter values of the Turbine generator and the exact transfer function for the Grid (city) that the paper has access to. However, by simulating our developed feed forward design it is easy to demonstrate that feed forward theory is something that should be consider in all control system designs.