Supply Chain Drivers and Obstacles

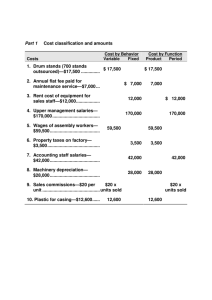

advertisement

Supply Chain Management Lecture 26 Detailed Outline • Thursday April 22 Simulation game briefing – Simulation game description – FCQs • Tuesday April 27 Review – Simulation strategy – Formula sheet (available online) – Review final • Thursday April 29 Simulation Game – Thursday December 10 is the last day to turn in homework • Tuesday May 4 Final 7:30pm – 10:00pm Teams The Supply Chain Game • Simulation game description: http://co.responsive.net/sc/colorado/Assign1/ • Simulation game login: http://co.responsive.net/SupplyChain/SCAdmin The Supply Chain Game • Manage the supply chain for the Jacobs Industries on the fictional continent of Pangea – Jacobs only product is an industrial chemical that can be mixed with air to form a foam (used in air conditioner retrofit kits) Assignment • You can make the following changes to the supply chain – Add capacity to the factory (increase only) Assignment • You can make the following changes to the supply chain – Change the order quantity – Change the reorder point Assignment • You can make the following changes to the supply chain – Change the type of transportation (mail or truck) Objective • It is now day 730, two years after Jacobs began producing and marketing the chemical. A new foam technology is in development at Jacobs that will render all production capacity and inventory of the current foam obsolete and worthless on day 1460. All customers are aware of the pending new technology and as a result, demand will decrease to zero on day 1460. – Maximize the cash generated by the foam technology over the remaining two years of its lifetime. On day 1460 the game will end and all inventory and capacity will become obsolete The winning team is the one with the highest cash position on day 1460 The Market • Jacobs Industries’ only product is an industrial chemical that can be mixed with air to form a foam that is – Lightweight, stable over a wide range of temperatures, a very efficient thermal insulator, a very efficient acoustic insulator • Jacobs sells its chemical to manufacturers of air conditioner retrofit kits. The manufacturers are all located in the region of Calopeia The Market • The chemical is shipped in small plastic drums at a price of $1450 a piece. – Demand for the chemical is highly seasonal but otherwise very stable. There are no long-run market trends, either upward or downward. – The size of orders is very random and arrive randomly throughout each 24-hour day. – If Jacobs cannot ship an order within 24 hours of receiving the order from the customer, the customer makes its purchase from a competitor without any loss of future demand. Demand • It is now day 730, two years after Jacobs began producing and marketing the chemical. 140 Demand 120 Forecast 100 80 60 40 20 0 0 200 400 600 800 1000 1200 1400 Operations • The current capacity of the factory is 20 drums per day. More factory capacity can be purchased at a cost of $50,000 per drum per day. For example, expanding the capacity by 10 drums per day for a total of 30 drums per day would be 10*$50,000 = $500,000. Capacity costs are incurred as soon as the capacity expansion begins. It takes 90 days to complete a capacity expansion. Capacity cannot be retired 20 units per day Unlimited storage Operations • Jacobs produces its chemical in batches, loads the chemical into small plastic drums, and then transports the drums from the factory to the warehouse by truck. The warehouse sends drums to customers as orders are received. The cost of fulfilling an order, including the cost of mailing the drum to the customer, is $150 per drum $1000 $150 by mail (1 day) $15,000 by truck (7 days) $150 $1,450 One truck can carry up to 200 drums Operations • Production in factories is carried out in batches, where each batch is an integer number of drums set by you. The cost to produce one batch equals $1500 plus the number of drums in the batch times $1000. For example, the cost to produce a batch of 10 drums is $1500 + 10*$1000 = $11,500. Drums won’t ship until batch is complete $1500 per batch Order quantity = batch size Operations • Both the costs of producing the batch and then shipping it to the warehouse are incurred as soon as production of the batch starts. If there is insufficient cash to pay for the production and shipping of the batch, the factory will remain idle • Production of a batch is triggered when the finished goods inventory (both en route to the warehouse and in the warehouse) fall below the order point • Holding costs for one drum for one year equal $100, whether the drum is en route to a warehouse or the drum is physically in the warehouse. There are no such holding costs for work-in-process inventory in the factory • Jacobs earns 10% interest per year on its cash, compounded daily Assignment • You can make the following changes to the supply chain – – – – Add capacity to the factory (increase only) Change the order quantity (i.e. batch size) Change the reorder point Change the type of transportation (mail or truck) Decisions • Add capacity to the factory (increase only) 140 Demand 120 Capacity 100 80 60 40 20 0 0 100 200 300 400 500 600 700 Decisions • Change capacity of factory (increase only) 140 Demand 120 Lost demand 100 80 60 40 20 0 0 100 200 300 400 500 600 700 Decisions • Change the order quantity (i.e. batch size) • Change the reorder point • Change the type of transportation (mail or truck) Grading • Based on your analysis (see handout) Hints • Create a general strategy beforehand • All inventory and capacity will be obsolete at the end of the simulation • Most investments pay off, but it takes time Analysis questions • When are transportation cost per drum minimized? • What is minimum transportation cost per drum? • What is the physical annual holding cost of one drum? • What is the financial annual holding cost of one drum (what is the opportunity cost)? • What is the total holding cost of one drum? Analysis questions • Ignore the batch production cost. What is the maximum margin that can be obtained from selling one drum? – – – – – – Retail price per drum Production cost per drum Minimum transportation cost per drum Minimum holding cost per drum Fulfillment cost per drum Maximum margin per drum